Knitted fabric shaping waste gas spraying equipment with heat energy recovery function

A knitted fabric and heat recovery technology, applied in fabric surface trimming, heating/cooling fabrics, textiles and papermaking, etc., can solve problems such as heat dissipation, residual impurities, environmental pollution, etc., and achieve the effect of avoiding waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

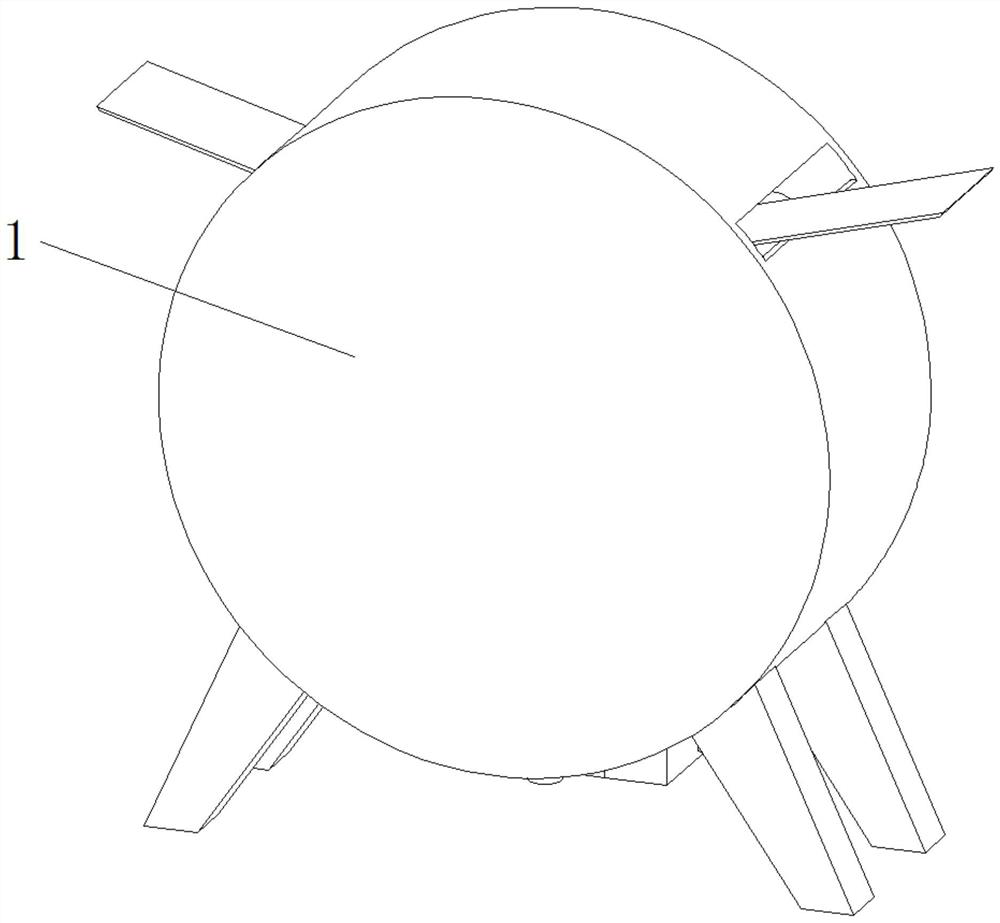

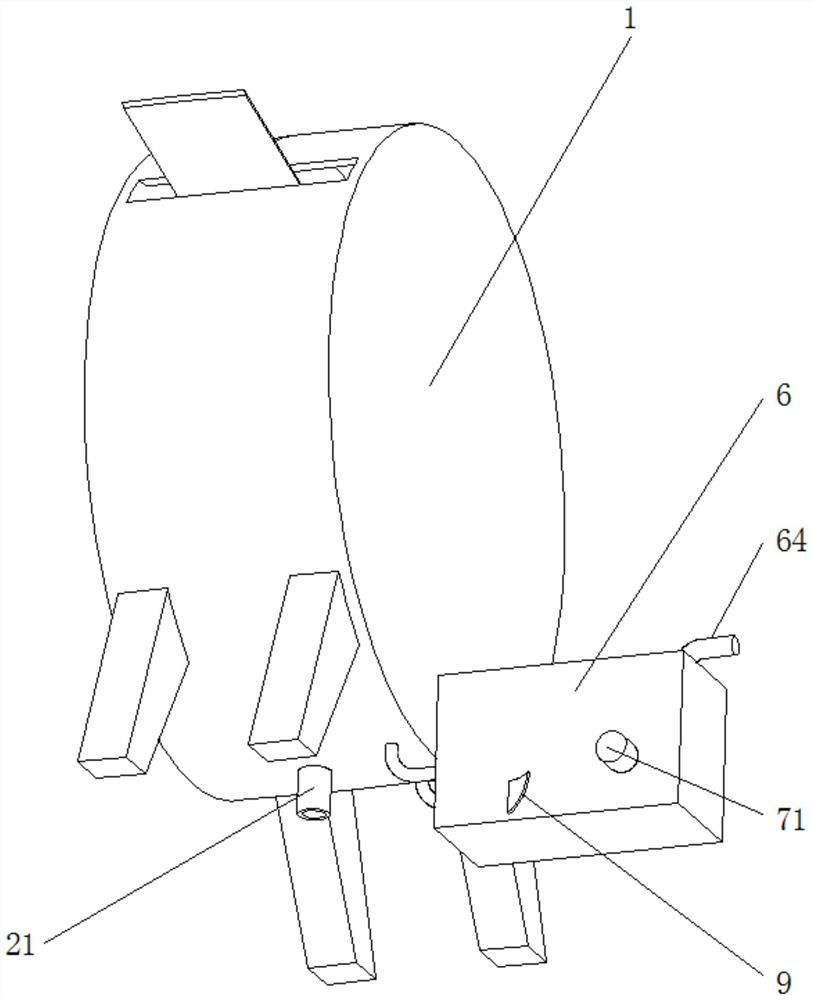

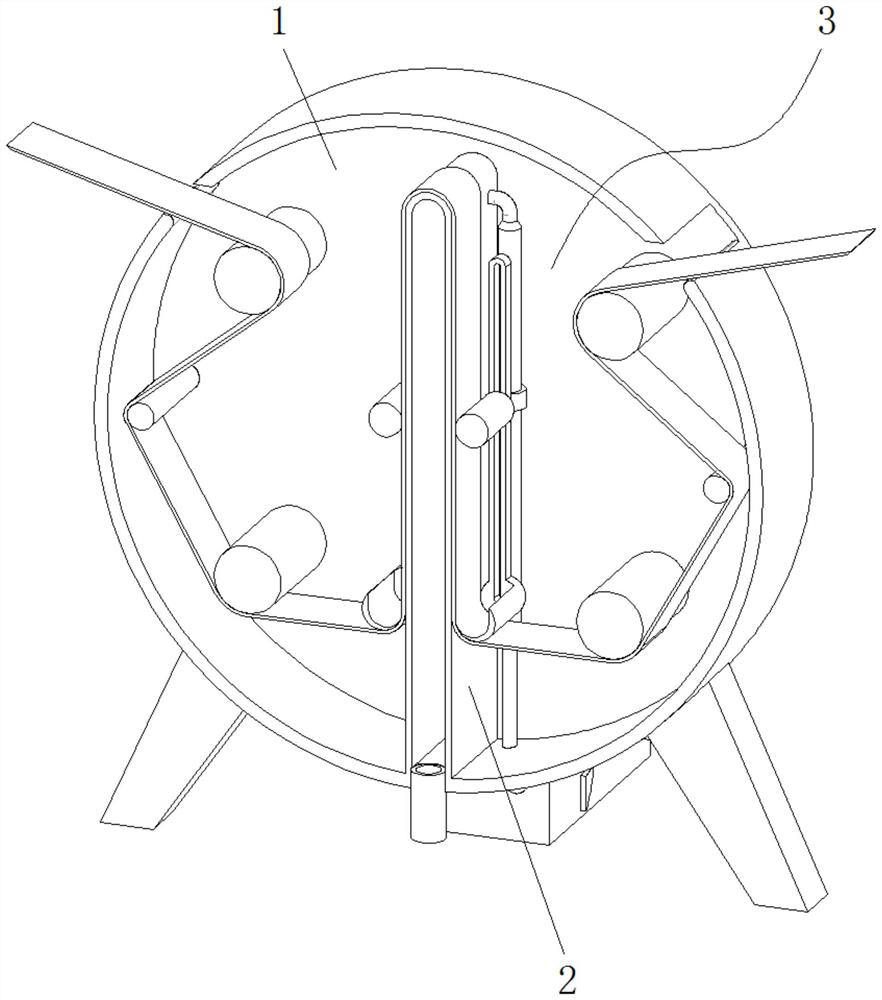

[0028] The embodiment of the present invention provides a knitting fabric shaping waste gas spraying equipment with heat energy recovery function, such as Figure 1-9 As shown, a circular box 1 is included, and a vertical plate 2 is welded in the circular box 1. The interior of the vertical plate 2 is hollow, and the left and right sides of the vertical plate 2 are symmetrically fixed with stereotyped components 3 . The circular box 1 is pivotally connected with a plurality of traction rollers. as attached Figure 4 As shown, the fabric enters from the left end of the circular box 1, passes through the shaping assembly 3 along the cloth running direction, then moves along the surface of the vertical plate 2, and finally moves out from the right end of the circular box 1.

[0029] The sizing assembly 3 is used to attach the fabric to the surface of the vertical plate 2, and the round box 1 back is fixedly equipped with a processing box 6. The shaping assembly 3 includes a dr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com