Engineering paving process for preparing sponge city water permeable concrete road by using steel slags

A technology for permeable concrete and sponge city, which is applied in the field of paving technology of permeable concrete road engineering made of steel slag for sponge city, can solve problems such as occupying land, and achieve the effects of reducing pollution and damage, reducing material cost and improving utilization rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

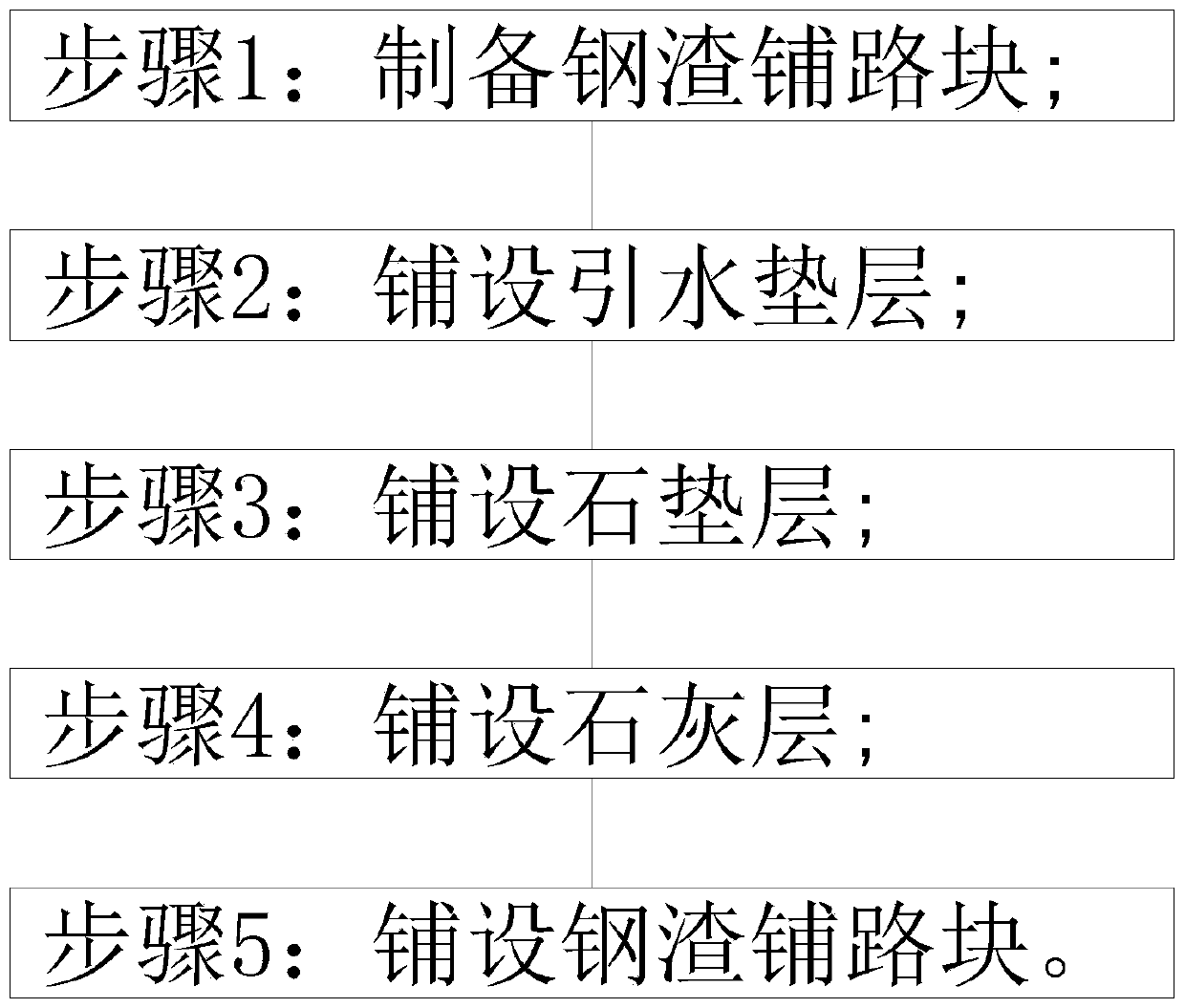

[0026] A kind of steel slag is made sponge city permeable concrete road project pavement technology, it is characterized in that, this technology comprises:

[0027] Step 1: Prepare steel slag paving blocks, use the crushing machine to support the dry steel slag on the stone crusher, sandstone grade and fly ash grade steel slag blocks, and mix the raw materials after drying and crushing the steel slag with curing agent, lime, siliceous additives, and water , put it into a hydraulic press for molding, and the formed green body is sent into a hydrothermal reaction kettle for hydrothermal curing treatment, and the raw materials after hydrothermal curing treatment are crushed, and then added to 425 cement concrete as aggregate;

[0028] Step 2: Lay the water diversion cushion, and use reinforced concrete to lay the bottom panel for guiding the water flow. The section of the panel is an isosceles triangle structure, and the two same angles in the isosceles triangle structure are bot...

Embodiment 2

[0042] A kind of steel slag is made sponge city permeable concrete road project pavement technology, it is characterized in that, this technology comprises:

[0043] Step 1: Prepare steel slag paving blocks, use the crushing machine to support the dry steel slag on the stone crusher, sandstone grade and fly ash grade steel slag blocks, and mix the raw materials after drying and crushing the steel slag with curing agent, lime, siliceous additives, and water , put it into a hydraulic press for forming, and the formed green body is sent into a hydrothermal reaction kettle for hydrothermal curing treatment;

[0044] Step 2: Lay the water diversion cushion, and use reinforced concrete to lay the bottom panel for guiding the water flow. The section of the panel is an isosceles triangle structure, and the two same angles in the isosceles triangle structure are both less than 15°. There are several drainage grooves;

[0045] Step 3: Lay the stone cushion, pave with coarse sand, the c...

Embodiment 3

[0058] A kind of steel slag is made sponge city permeable concrete road project pavement technology, it is characterized in that, this technology comprises:

[0059] Step 1: Prepare steel slag paving blocks, use the crushing machine to support the dry steel slag on the stone crusher, sandstone grade and fly ash grade steel slag blocks, and mix the raw materials after drying and crushing the steel slag with curing agent, lime, siliceous additives, and water , put it into a hydraulic press for forming, and the formed green body is sent into a hydrothermal reaction kettle for hydrothermal curing treatment;

[0060] Step 2: Lay the water diversion cushion, and use reinforced concrete to lay the bottom panel for guiding the water flow. The section of the panel is an isosceles triangle structure, and the two same angles in the isosceles triangle structure are both less than 15°. There are several drainage grooves;

[0061] Step 3: Lay the stone cushion, pave with coarse sand, the c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com