Sand discharging device of sand silo

A technology for sand bins and bin walls, which is applied in the field of storage and discharge devices for sand materials, and can solve problems such as inability to realize switching actions, fast flow speed, and deformation of mandrel mold shells, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

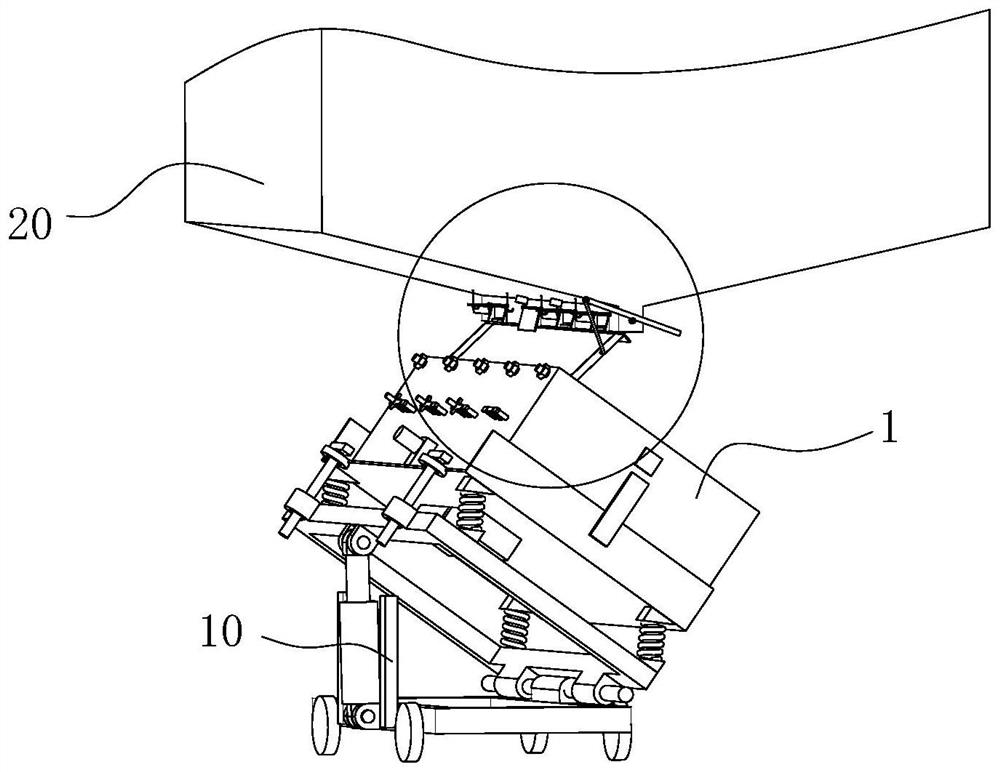

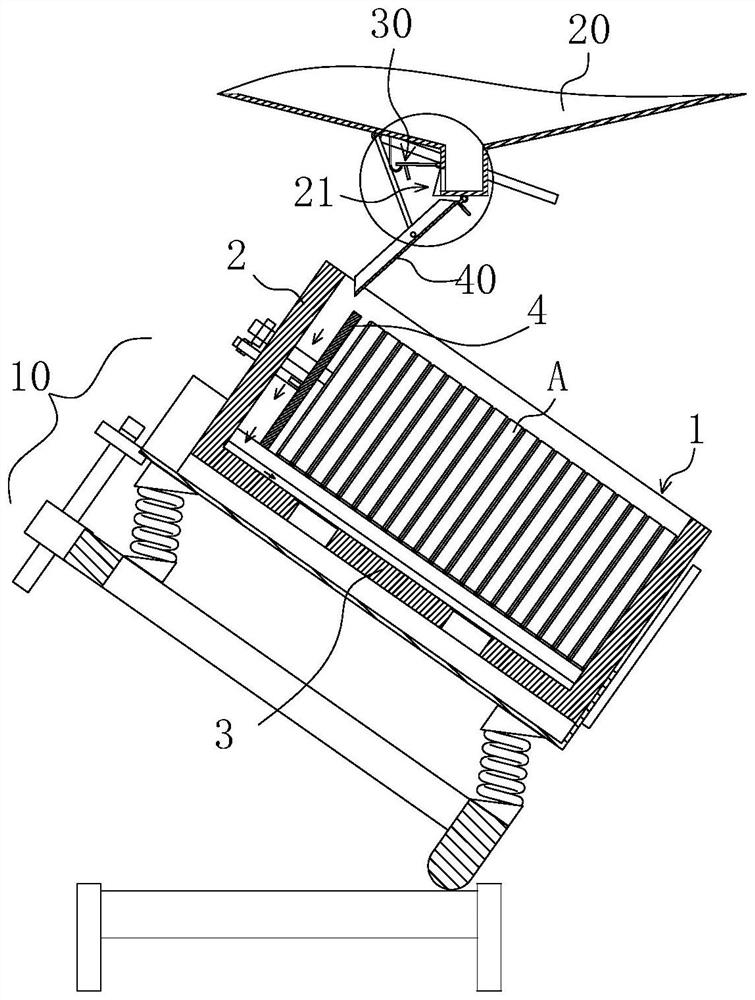

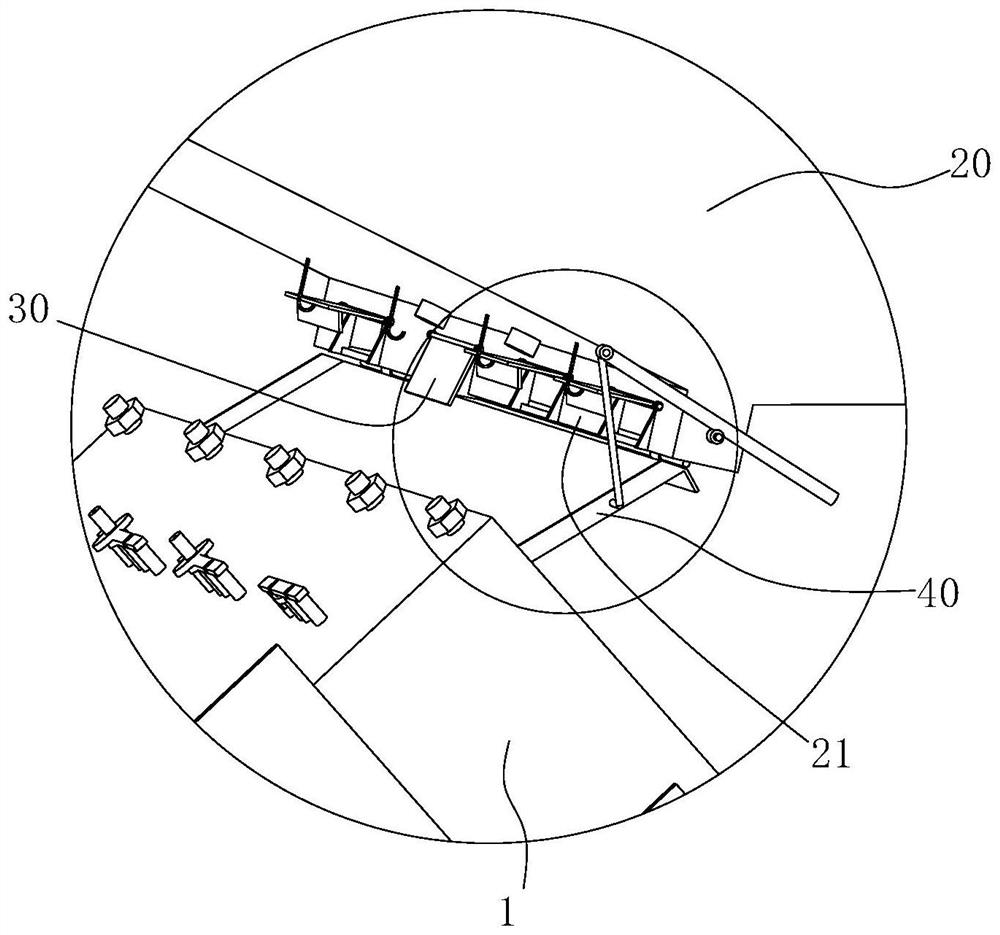

[0013] Such as figure 1 , 2 As shown, the bracket 10 will support the sand box 1 so that the bottom 3 of the box is in an inclined posture, which ensures that the cavity between the bottom 3 of the box and the bottom of the core type A of the coated sand shell presents an oblique posture, and the sand box For the structure, please refer to the patent document named "Sand Shell Core Casting Box" (document number CN 109226696A). At this time, the flow path of the outer molding sand flowing from the sand outlet 21 is limited to reach the inner side of the upper edge of the box wall 2 on the high side This part is also the space between the box wall 2 and the movable platen 4 that clamps the coated sand shell core type A set in the sand box 1. The falling sand enters from this place and moves along the box wall 2 and the movable platen 4. The clamp cavity between the pressing plates 4 falls to the high position of the box bottom 3, and then flows from the high position of the box...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com