Multi-shaft variable-speed thermal washing module and thermal washing method thereof

A technology of hot washing and modules, applied in chemical instruments and methods, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problem of large impact on the next batch of materials, large volume and space occupation, small mechanical friction, etc. problems, to achieve the effect of reducing investment and land occupation, improving efficiency and increasing friction strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

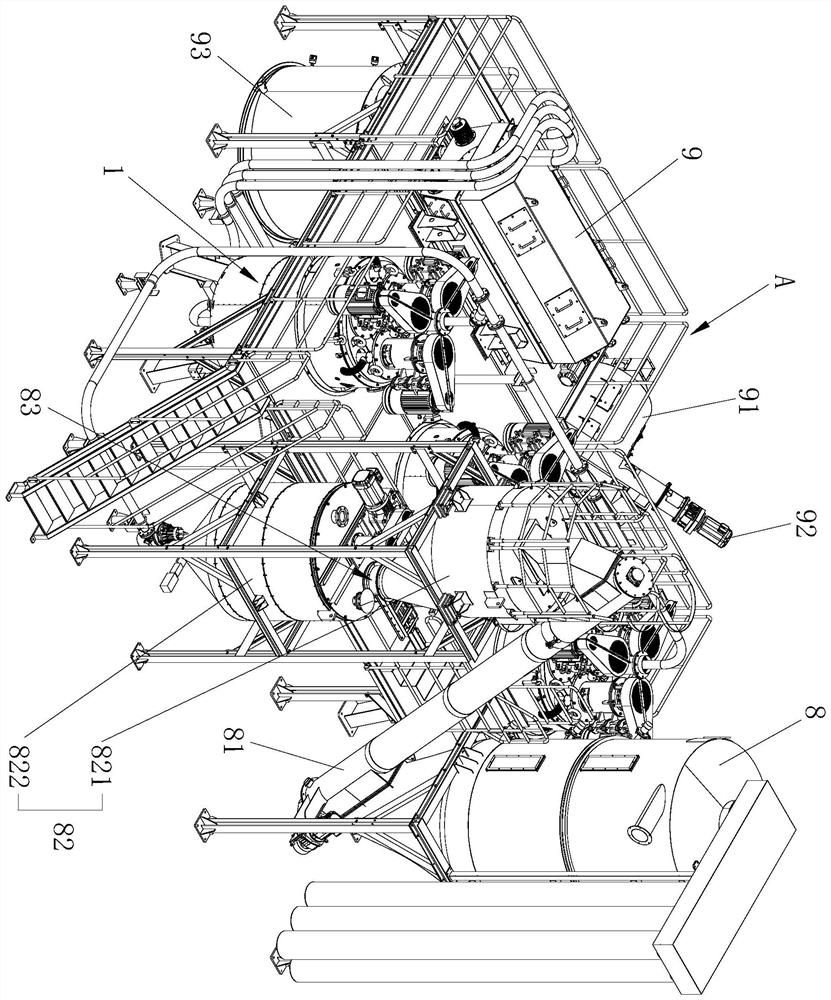

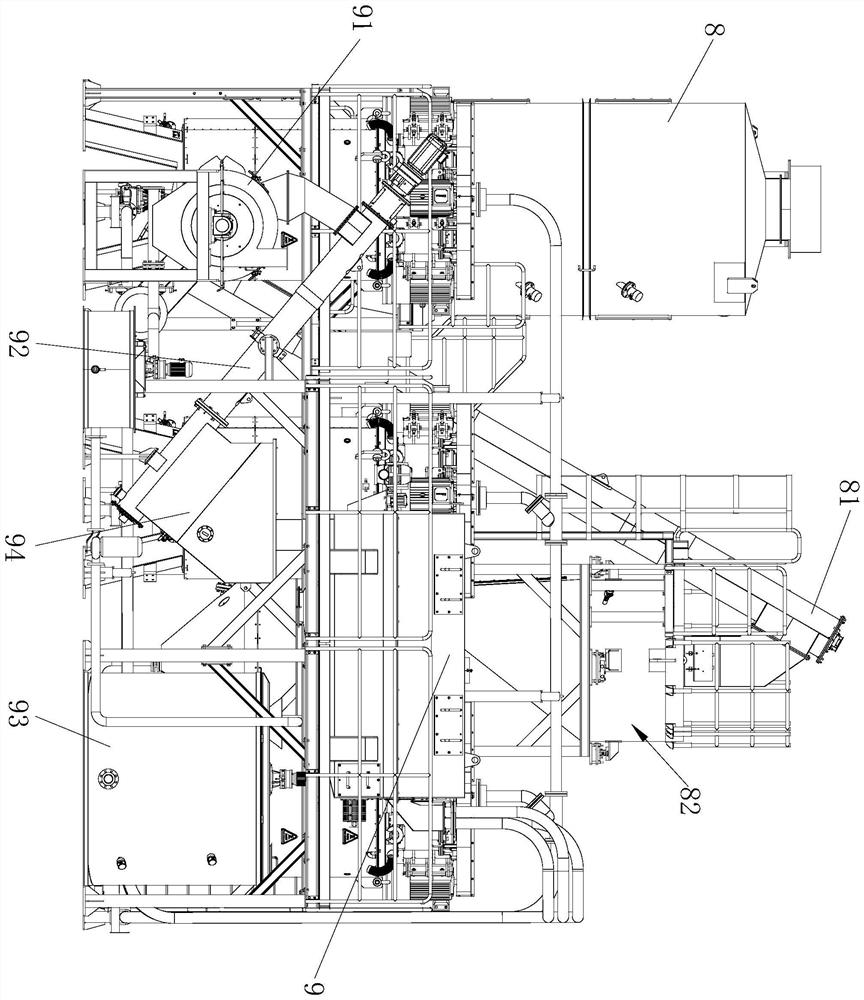

[0067] refer to figure 1 , is the multi-axis variable-speed heat washing module disclosed in the present invention, including a storage assembly and a dehydration assembly, and is characterized in that it also includes one or more multi-axis variable-speed heat washing machines 1, and the multi-axis variable-speed heat washing machines 1 are respectively Connect with storage components and dehydration components.

[0068] Among them, the multi-axis variable speed thermal washing machine 1 includes a cleaning chamber 10, a variable speed driving device 2 and a rotating mechanism 3. The rotating mechanism 3 is arranged in the inner cavity of the cleaning chamber 10 and is connected to the variable speed driving device 2. There are two or more groups, and the variable speed drive device 2 is used to adjust the rotating speed of the rotating mechanism 3 .

[0069] Two or more sets of rotating mechanisms 3 are rotated at variable speeds in the cleaning cavity 10 through the variab...

Embodiment 2

[0119] A multi-axis variable-speed hot-washing module differs from Embodiment 1 in that three sets of rotating mechanisms 3 are provided, and the three sets of rotating mechanisms 3 share one variable-speed driving device 2 . The three groups of rotating mechanisms 3 share one variable speed drive device 2 , so that the three groups of rotating mechanisms 3 can operate synchronously.

Embodiment 3

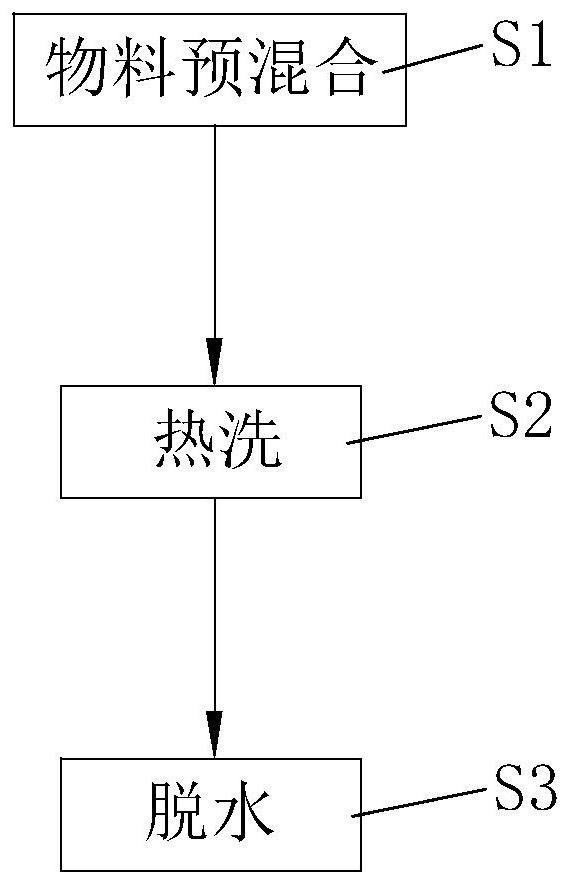

[0120] Embodiment 3: A hot-washing method for a multi-axis variable-speed hot-washing module, the difference from Embodiment 1 is that in step S2:

[0121] The steps of regular low-speed soaking and washing include: adjusting the variable-speed driving device 2 of the multi-axis variable-speed thermal washing machine 1, so that the variable-speed driving device 2 drives a plurality of cleaning blade shafts 31 to perform low-speed pre-soaking and cleaning for 20 minutes at a speed of 15 r / min. The steps of regular high-speed friction washing include: adjusting the variable speed drive device 2 of the multi-axis variable speed thermal washing machine 1 again, so that the rotation speed of multiple cleaning blade shafts 31 is increased to 500r / min for high-speed cleaning, which lasts for 20 minutes.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com