Safe cantilever crane

A cantilever crane, safety-type technology, applied in the direction of cranes, clockwork mechanism, load hanging components, etc., can solve the problems of over-limited hoisting height, excessive wire rope unwinding, operation safety accidents, etc., and achieve safe operation control Strong ability, avoiding excessive rotation, and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] In order to further understand the content, characteristics and efficacy of the invention, the following examples are given for detailed description.

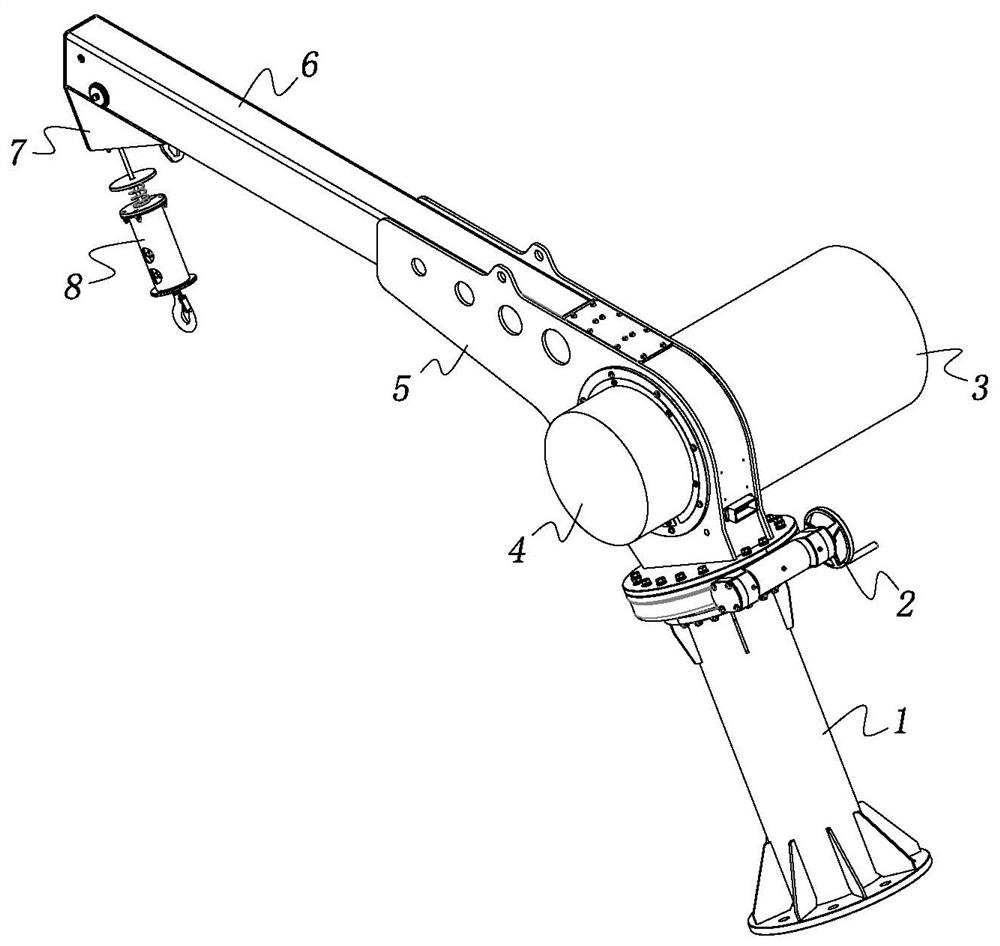

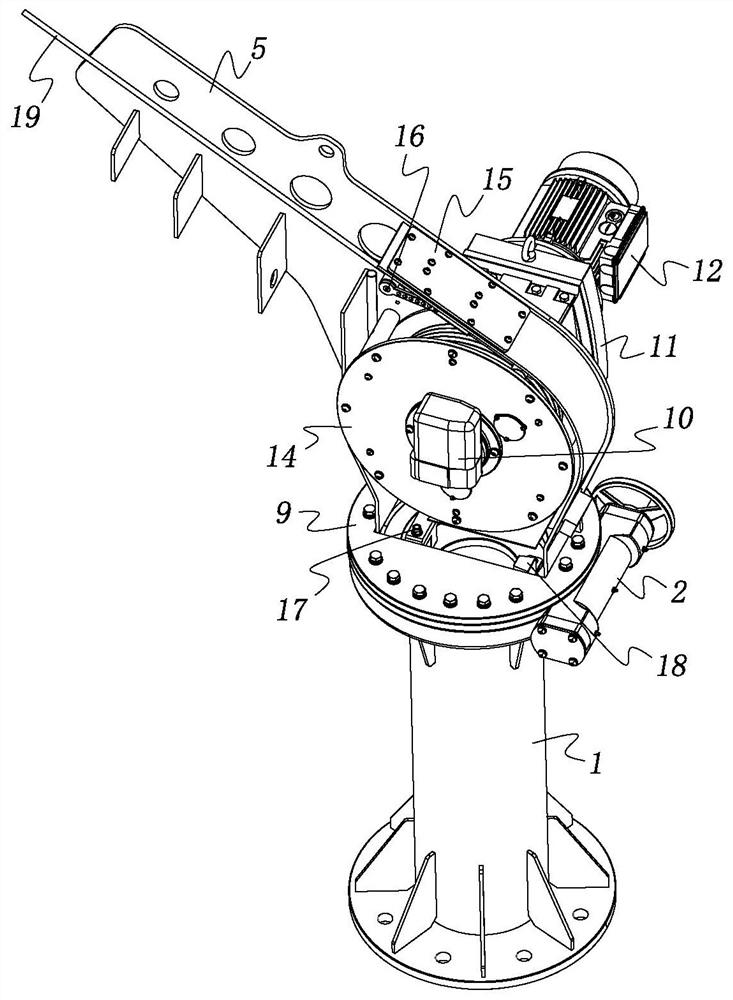

[0030] See Figure 1 , the safe cantilever crane column 1 and the crane host of the invention are provided with a rotary driving device 2 between the column 1 and the crane host. Among them, the column 1 is used for support, so that the crane host is at a certain height position, and the cantilever crane is installed and fixed at a specific position. The rotary driving device 2 is used to drive the crane host to rotate and move, so as to adjust the lifting position.

[0031] Column 1 is made of thick wall metal pipe, and flange plates are set at the top and bottom. The flange plates at the bottom are installed and fixed with strong bolts, such as fixed on the platform of wind power facilities or the deck of ship facilities.

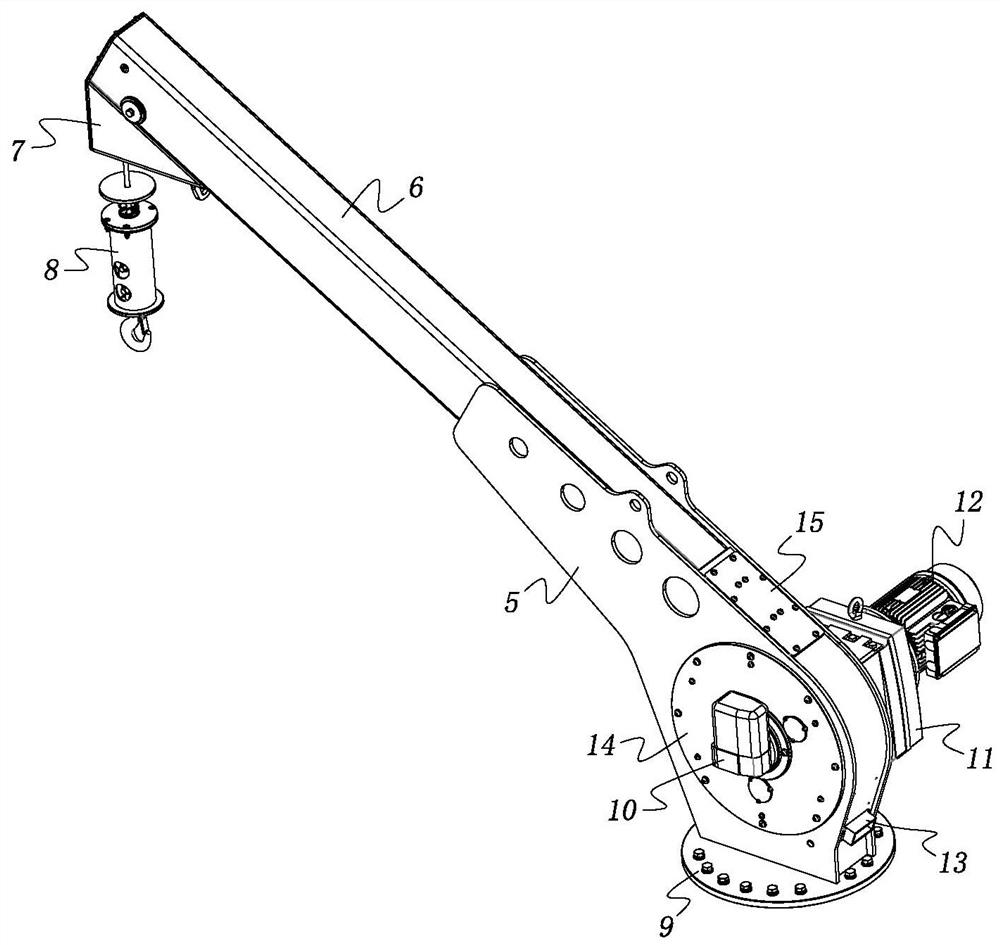

[0032] See Figure 2 、 Figure 3 and Figure 5 It can be seen that the crane host includes the host hous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com