Zinc-based high-resistance film coating liquid, preparation method thereof and preparation method of zinc-based high-resistance film

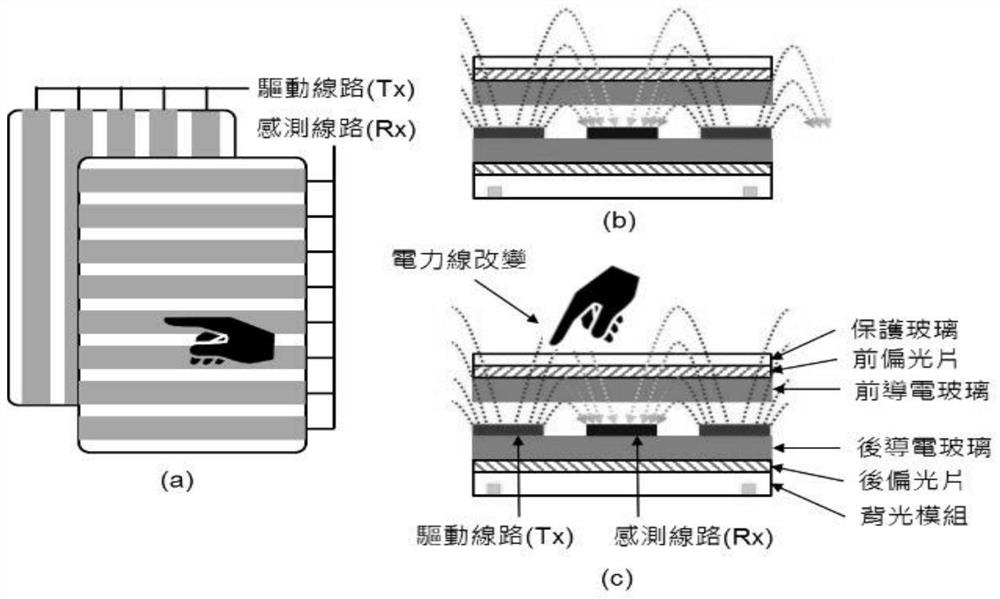

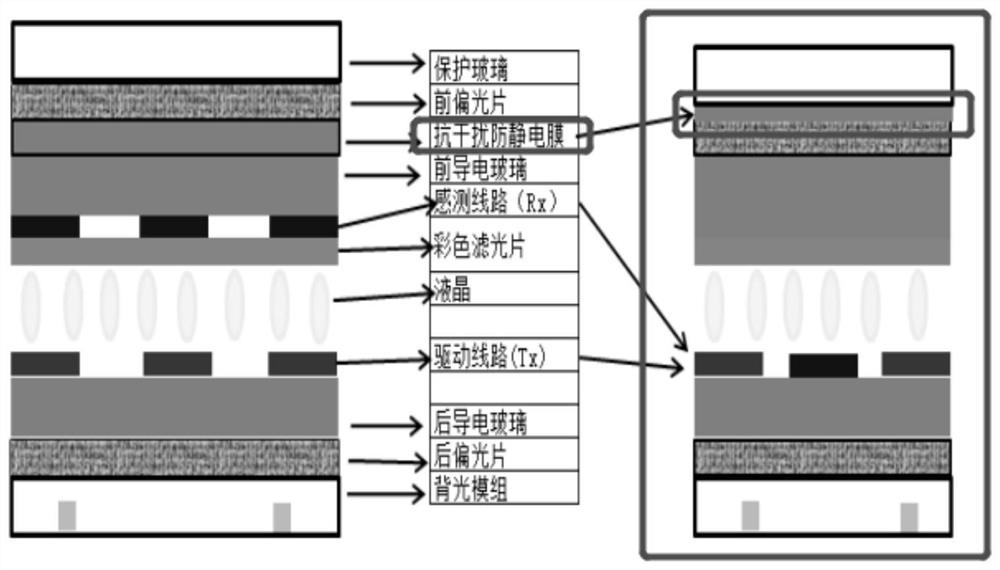

A technology of large resistance and coating solution, which is applied in the preparation of zinc-based high-resistance thin film and the field of zinc-based high-resistance thin film coating solution, which can solve the problems of difficult to achieve touch effect, occlusion, and affect the touch effect, so as to maintain stability , Reduce the resistance change of large resistors, and the effect of high light transmittance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0034] The application also provides a method for preparing a zinc-based high-resistance thin film coating solution, comprising the following steps:

[0035]After mixing water, ethanol and a dispersant, adding a zinc-based alloy, adding a thickener, and stirring to obtain a zinc-based high-resistance thin film coating solution.

[0036] The preparation sequence of the above zinc-based high-resistance thin film coating solution can ensure good uniformity of the thin film. During the above mixing process, the whole process is carried out under stirring; the stirring speed is 100-200 rpm, and the stirring time is 60-120 min.

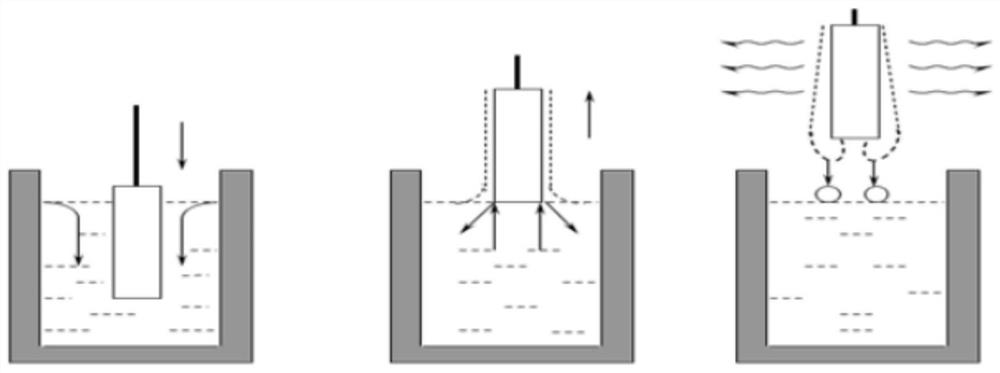

[0037] The present application also provides a method for preparing a zinc-based high-resistance thin film, which uses the dipping and pulling method to dip the entire cleaned substrate into the coating solution, and then immerses it at a controlled uniform speed. The substrate is pulled out of the coating solution smoothly, and a uniform liquid film is fo...

Embodiment 1

[0054] Vacuum absorb the cleaned PET substrate on the surface of the workbench, the vacuum pressure is 0.6Pa; the PET substrate enters the coating solution 1 to pull the coating, and then the rotary table automatically rotates the coating solution 2 to the bottom of the substrate, and then the substrate descends into Coating solution 2 pulls the coating, and the subsequent film layers are completed in sequence; the pulling speed is 120 μm / s; the immersion time is 150s; the number of coating times is 4 times; the solution temperature is 19°C;

[0055] After the coating is completed, let it dry naturally for 20 minutes at a temperature of 25°C and a film thickness of 120 μm;

[0056] Put the air-dried substrate into a vacuum drying oven, raise it to 100°C at 5°C / min and keep it for 1.3 hours, then raise the temperature to 240°C and keep it for 40 minutes to dry, then naturally drop to room temperature, the vacuum degree is 0.04Pa, the drying process can pass Inject 20sccm of oxy...

Embodiment 2

[0058] Vacuum absorb the cleaned PET substrate on the surface of the workbench, the vacuum pressure is 0.8Pa; the PET substrate enters the coating solution 1 to pull the coating, and then the rotary table automatically rotates the coating solution 2 to the bottom of the substrate, and then the substrate descends into Coating solution 2 pulls the coating, and the subsequent film layers are completed in sequence; the pulling speed is 160 μm / s; the immersion time is 165 s; the number of coating times is 5 times; the solution temperature is 22°C;

[0059] After the coating is completed, let it dry naturally for 20 minutes at a temperature of 25°C and a film thickness of 150 μm;

[0060] Put the air-dried substrate into a vacuum drying oven, raise it to 105°C at 5°C / min and keep it for 1.5h, then raise the temperature to 260°C and keep it for 45min to dry, then naturally drop to room temperature, the vacuum degree is 0.05Pa, the drying process can pass Inject 150sccm nitrogen gas a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com