Rare earth feed liquid feeding and conveying device for rare earth separation and extraction

A rare earth material liquid and conveying device technology, applied in the field of conveying equipment, to avoid mixed pollution, improve separation effect, and ensure the effect of purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

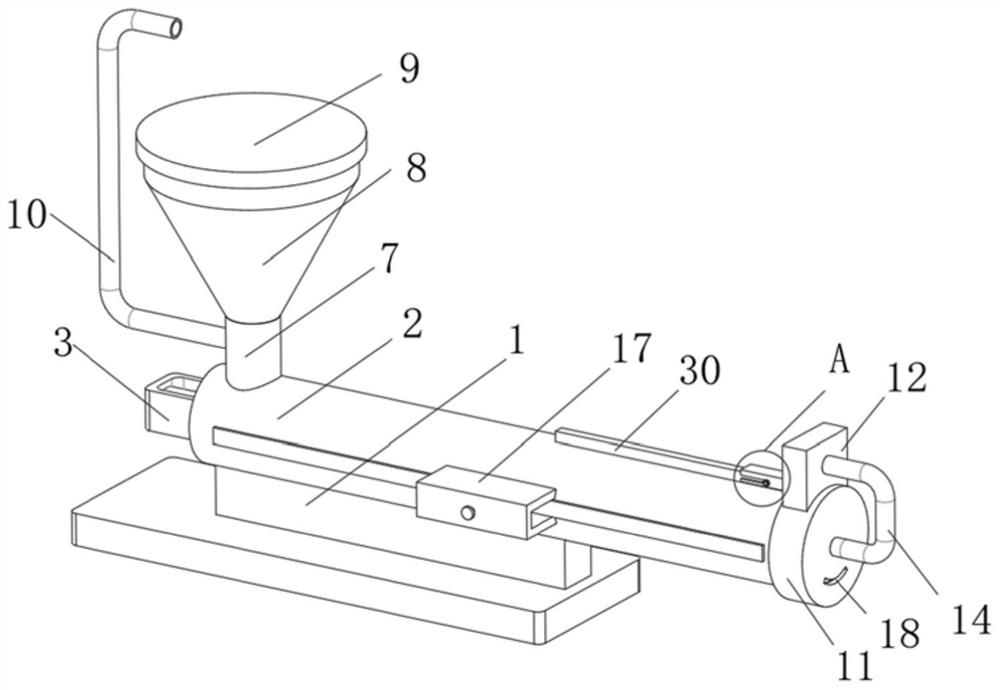

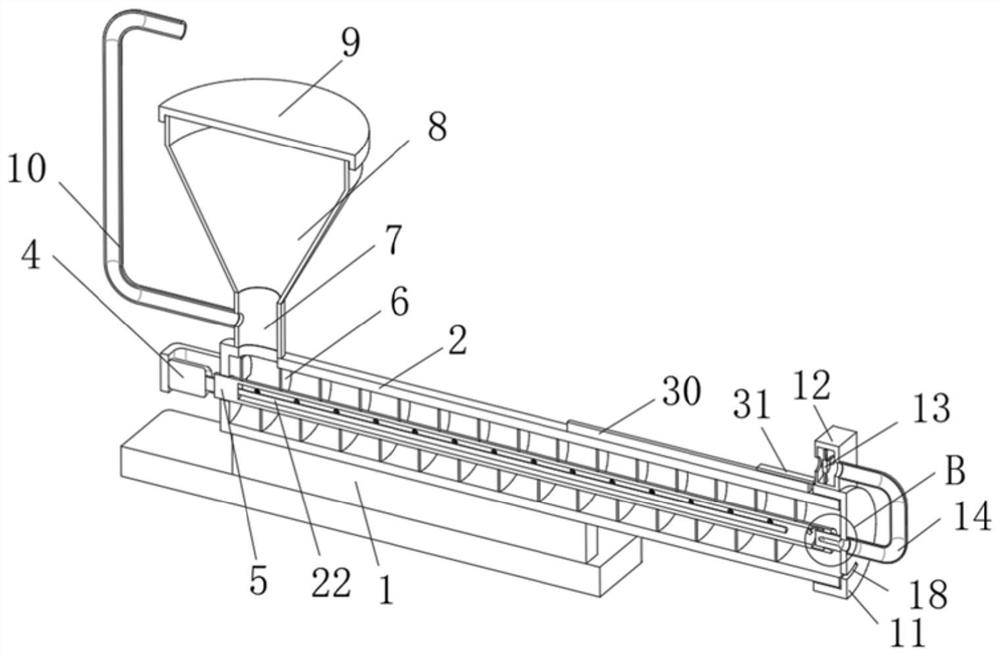

[0034] The first embodiment: as figure 1 , image 3 , Figure 4 and Figure 6 As shown, when the upper extraction liquid needs to be sucked, the adjusting screw 175 is loosened outwards, and the sealing plate 172 and the adjusting plate 171 are moved outward for a small distance, so that the adjusting plate 171 is away from the screw blade 6, and the suction pipe 10 is placed in the upper extraction liquid, and the sealing cover 9 is covered, and the suction fan 13 is started, so that the suction fan 13 sucks the air in the delivery pipe 2 through the communication pipe 14 and the installation cover 11, so that the air pressure inside the delivery pipe 2 Decrease, so that the upper material liquid in the extraction bottle is sucked into the feed pipe 7 along the suction pipe 10 and injected into the delivery pipe 2, after the material liquid is sucked, the adjusting screw 175 is pushed to reset the adjusting plate 171, and the suction fan is turned off 13. Start the motor 4...

no. 2 example

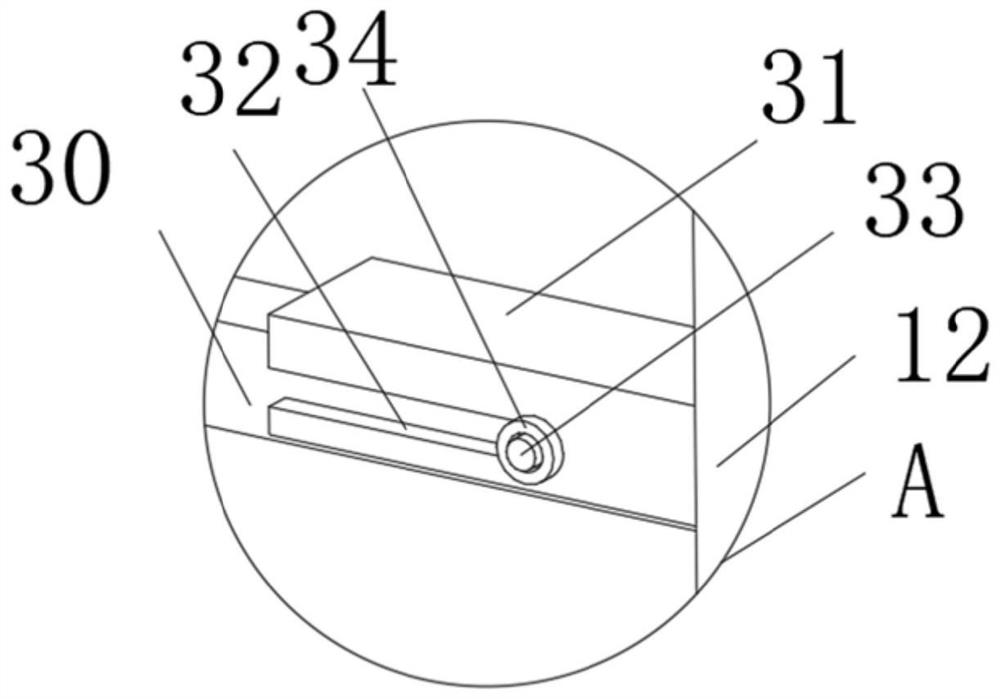

[0039] The second embodiment: as figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 and Figure 8 As shown, when the inner wall of the delivery pipe 2 needs to be flushed, the threaded cap 34 is loosened, and the movable plate 31 is pushed to move to the left, so that the sealing sleeve 15 slides in the inner cavity 20 of the rotating shaft 5, so that the curvature of the outer surface of the sealing sleeve 15 The hole 16 communicates with the annular groove 19, and the end surface of the installation sleeve 12 is filled with cleaning water, so that the cleaning water enters the sealing sleeve 15 through the communication pipe 14, and enters the inside of the rotating shaft 5 through the curved hole 16 inside the sealing sleeve 15, Start motor 4 simultaneously, make motor 4 drive rotating shaft 5 rotations, and along with clear water feeds, clear water amount increases gradually, and promotes the movable plug 26 in the fixed pipe 24 to slide outwards, simultaneously N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com