Foundation pit covering and excavating structure for construction under bridge side traffic opening and construction method

A construction method and foundation pit technology, which is applied in the direction of foundation structure engineering, underwater structures, excavation, etc., can solve the problems of inconvenient traffic opening of the road under the bridge, limited clearance above the foundation pit, and the influence of adjacent bridge piers, so as to save time and Funds, good effect of opening to traffic, small vibration and deformation of opening to traffic

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

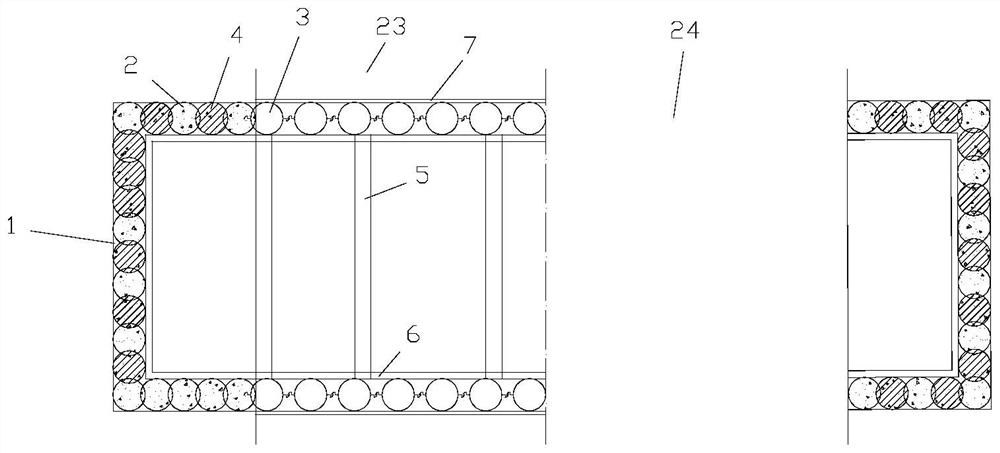

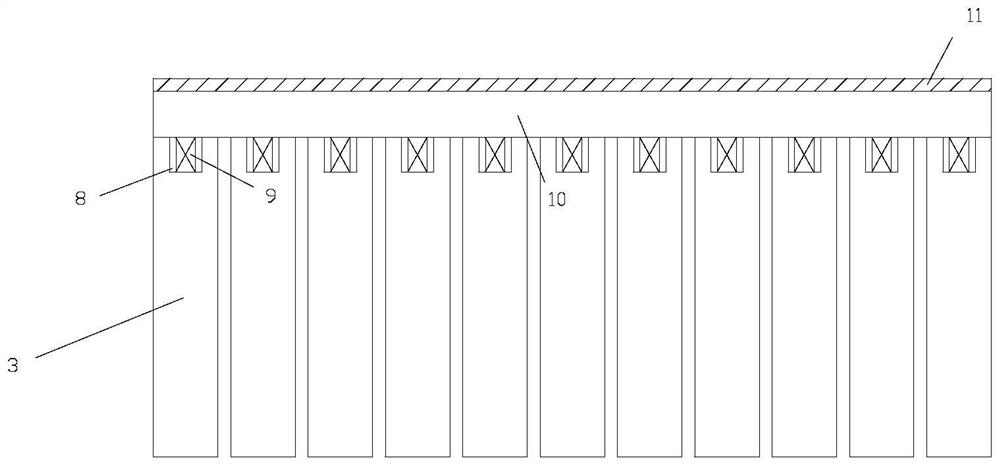

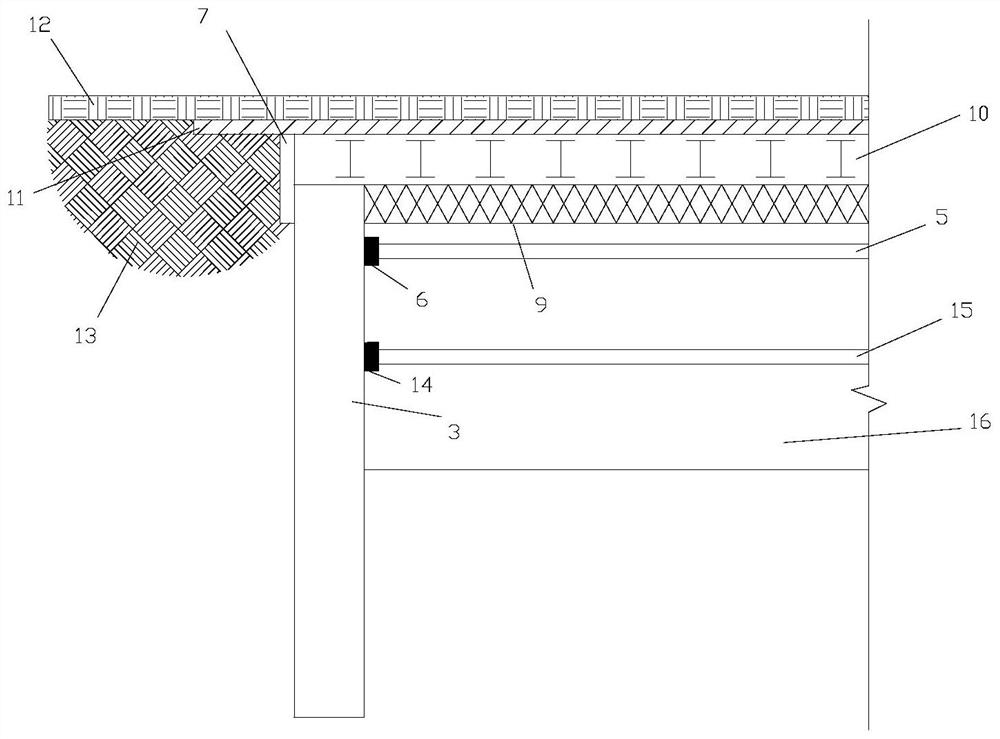

[0048]Embodiment 1 of the present application provides a foundation pit cover and excavation structure under the bridge open to traffic, including crown beam 1, plain concrete pile 2, steel pipe pile 3, reinforced concrete pile 4, upper inner support 5, upper purlin 6, retaining Soil plate 7, groove 8, Bailey beam 9, I-beam 10, steel plate 11, asphalt surface layer 12, roadbed 13, lower purlin 14, lower inner support 15, pit bottom 16, guardrail 17, short steel pipe 18, Flange 19, lock 20, grouting pipe 21, grouting body 22. The foundation pit under the bridge is supported by large-diameter steel pipe piles 3. The steel pipe piles 3 are formed by connecting multiple short steel pipes 18 with locks 20 through flanges 19. A steel pipe pile 3 is embedded and overlapped with the plain concrete pile 2 of the occlusal pile, and a grouting pipe 21 is welded at the overlap between the outermost steel pipe pile 3 and the plain concrete pile 2 . The top of the steel pipe pile 3 is prov...

Embodiment 2

[0058] Embodiment 2 of the present application provides a construction method for constructing a foundation pit cover excavation structure while opening to traffic under the bridge, comprising the following steps:

[0059] Step 1: Set up the occlusal piles for supporting the foundation pit outside the bridge. The occlusal piles are formed by overlapping the reinforced concrete piles 4 and the plain concrete piles 2, and a reinforced concrete crown beam 1 is poured on the top of the occlusal piles.

[0060] Step 2: Press into the steel pipe pile 3 welded with the grouting pipe 21 on the side of the plain concrete pile 2 near the bridge side, the steel pipe pile 3 overlaps the plain concrete pile 2 for a certain length, and the overlapping part of the steel pipe pile 3 and its The lock catch 20 is embedded in the plain concrete pile 2 . The steel pipe pile 3 adopts multi-section short steel pipes 18 to be pressed in by using the pressure-holding type static pressure pile foundat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com