Method for reducing viscosity of heavy oil in heavy oil reservoir and application

A technology for heavy oil reservoirs and heavy oil viscosity, which is applied in chemical instruments and methods, earthwork drilling, drilling compositions, etc., can solve the problems of insufficient thin oil production, poor effect of reducing heavy oil viscosity, and natural gas dissolution Low capacity and other problems, to achieve the effect of improving the recovery effect of heavy oil, improving the fluidity of heavy oil, and improving the fluidity of heavy oil

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

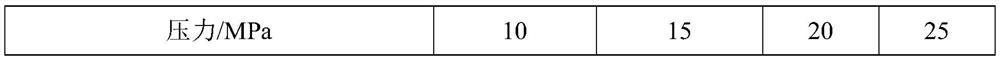

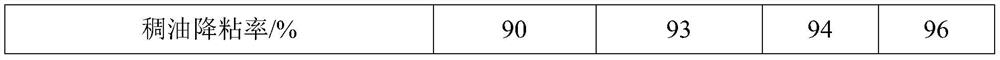

[0045] For ordinary heavy oil taken from an oilfield in the east, according to the method of the present invention, under different pressure conditions, the viscosity-reducing effect of heavy oil after contacting with dimethyl ether aqueous solution was tested, and the results are shown in Table 1. The crude oil has a viscosity of about 1000 mPa.s at 10 MPa and 60°C. It can be seen from the data in Table 1 that the aqueous solution of dimethyl ether can significantly reduce the viscosity of heavy oil, which can be used to improve the fluidity of heavy oil and improve the development effect. Compared with the injection of pure dimethyl ether (comparative example 1), the amount of dimethyl ether can be greatly reduced and the cost of heavy oil production can be reduced.

[0046] In this example, the mass ratio of dimethyl ether aqueous solution to heavy oil is 3:7.

[0047] Table 1 The effect of dimethyl ether aqueous solution on reducing the viscosity of heavy oil under differ...

Embodiment 2

[0050] For common heavy oil taken from an oil field in the west, according to the method in the present invention, the viscosity-reducing effect of heavy oil under different temperature conditions (pressure 20MPa) after contacting with dimethyl ether aqueous solution was tested. The viscosity of the heavy oil at 20MPa and 70°C is about 6000mPa.s. It can be seen from the data in Table 2 that the dimethyl ether aqueous solution can significantly reduce the viscosity of heavy oil, which can be used to improve the fluidity of heavy oil and improve the development effect. Compared with the injection of pure dimethyl ether (comparative example 1), the amount of dimethyl ether can be greatly reduced and the cost of heavy oil production can be reduced.

[0051] In this example, the mass ratio of dimethyl ether aqueous solution to heavy oil is 3:7.

[0052] Table 2 The effect of dimethyl ether aqueous solution on reducing the viscosity of heavy oil at different temperatures (20MPa)

...

Embodiment 3

[0055] For the super heavy oil taken from a certain oil field, according to the method of the present invention, under different temperature and pressure conditions, the viscosity-reducing effect of heavy oil after contacting with dimethyl ether aqueous solution was tested, and the results are shown in Table 3 and Table 4. The viscosity of the heavy oil at 20MPa and 70°C is about 21000mPa.s. It can be seen from the data in the table that the dimethyl ether aqueous solution can significantly reduce the viscosity of heavy oil, which can be used to improve the fluidity of heavy oil and improve the development effect. Compared with the injection of pure dimethyl ether (comparative example 1), the amount of dimethyl ether can be greatly reduced and the cost of heavy oil production can be reduced.

[0056] In this example, the mass ratio of dimethyl ether aqueous solution to heavy oil is 3:7.

[0057] Table 3 Effect of dimethyl ether aqueous solution on reducing viscosity of heavy ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com