Topdressing method for flue-cured tobacco

A flue-cured tobacco and fertilizer technology, applied in the field of tobacco cultivation, can solve the problems of increasing agricultural non-point source pollution, reducing the enthusiasm of tobacco growers, and increasing fertilizer input, and achieves the effects of low cost, reduced input, and increased nicotine content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

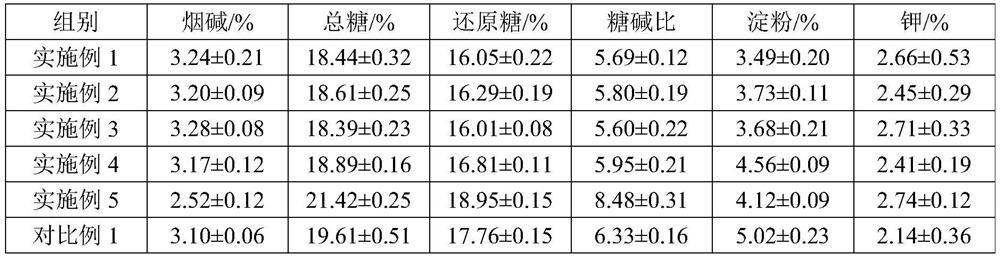

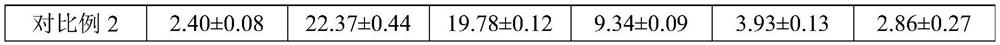

Examples

Embodiment 1

[0037] The present embodiment provides a kind of topdressing method that is used for flue-cured tobacco, comprises two topdressings, specifically as follows:

[0038] (1) Top dressing once

[0039] The fertilizer formula (dosage per mu) is: 20kg of tobacco-specific compound fertilizer, 3.26kg of agricultural potassium nitrate, 10kg of agricultural potassium sulfate, and the total amount of nitrogen in the fertilizer is 9kg. After mixing the fertilizers well, topdressing was divided into 4 times, the mass ratio of each dosage was 1:2:2:1, and the fertilizers were sprayed on 30d, 40d, 50d and 60d after transplanting respectively.

[0040] (2) Second topdressing

[0041] Immediately (within 1 day) after topping, carry out secondary topdressing by root irrigation. The topping adopts the conventional topping method of tobacco. The preparation method of the fertilizer used in the secondary top dressing is as follows: mix 7.14 kg of agricultural potassium nitrate (ie 1 kg of nitroge...

Embodiment 2

[0043] This example provides a topdressing method for flue-cured tobacco, which differs from Example 1 only in that the amount of polyaspartic acid is changed to 0.04 kg, and other conditions refer to Example 1.

Embodiment 3

[0045] This example provides a topdressing method for flue-cured tobacco, which differs from Example 1 only in that the amount of polyaspartic acid is changed to 0.06 kg, and other conditions refer to Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com