Additive and subtractive synchronous machining method and device capable of rapidly manufacturing or trimming grinding wheel

A technology for synchronous machining and dressing of grinding wheels, which is applied to manufacturing tools, grinding devices, metal processing equipment, etc., can solve problems such as reducing the use efficiency of grinding wheels, increasing the number of grinding wheel replacements, and failing to repair the grinding wheel, saving other energy. Consumption, improve dressing efficiency and save processing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

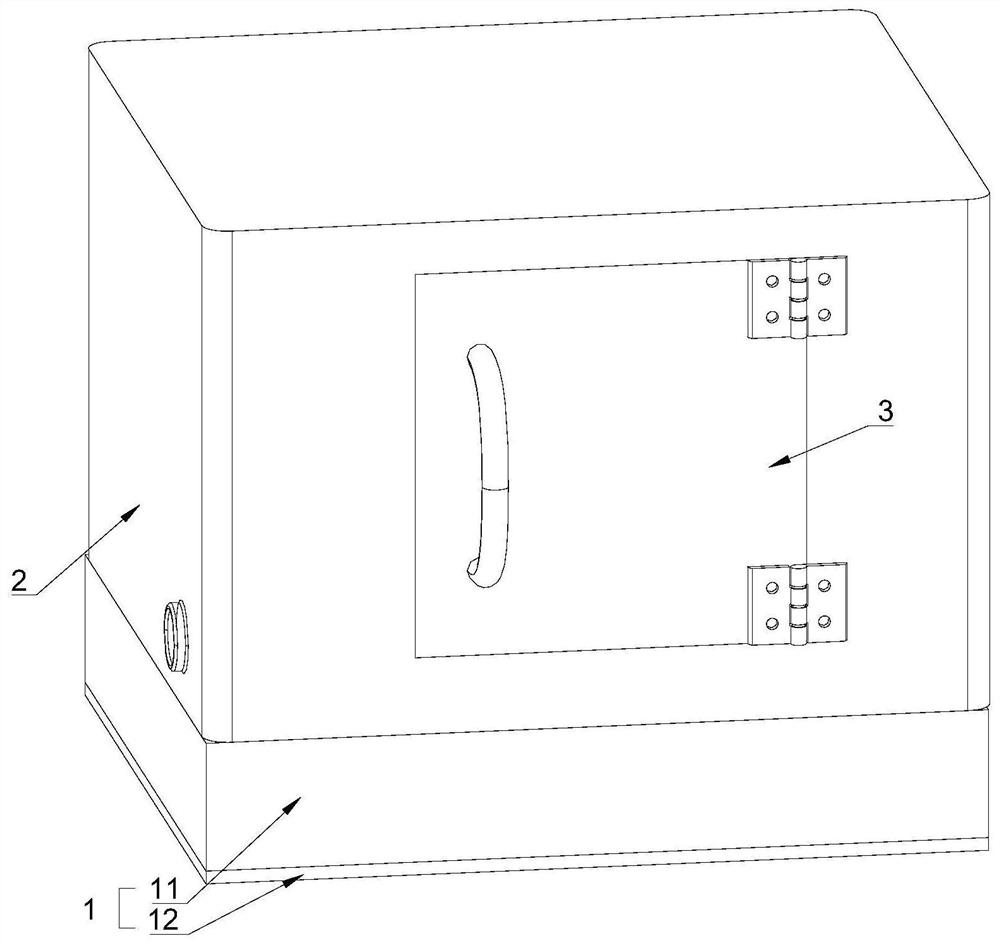

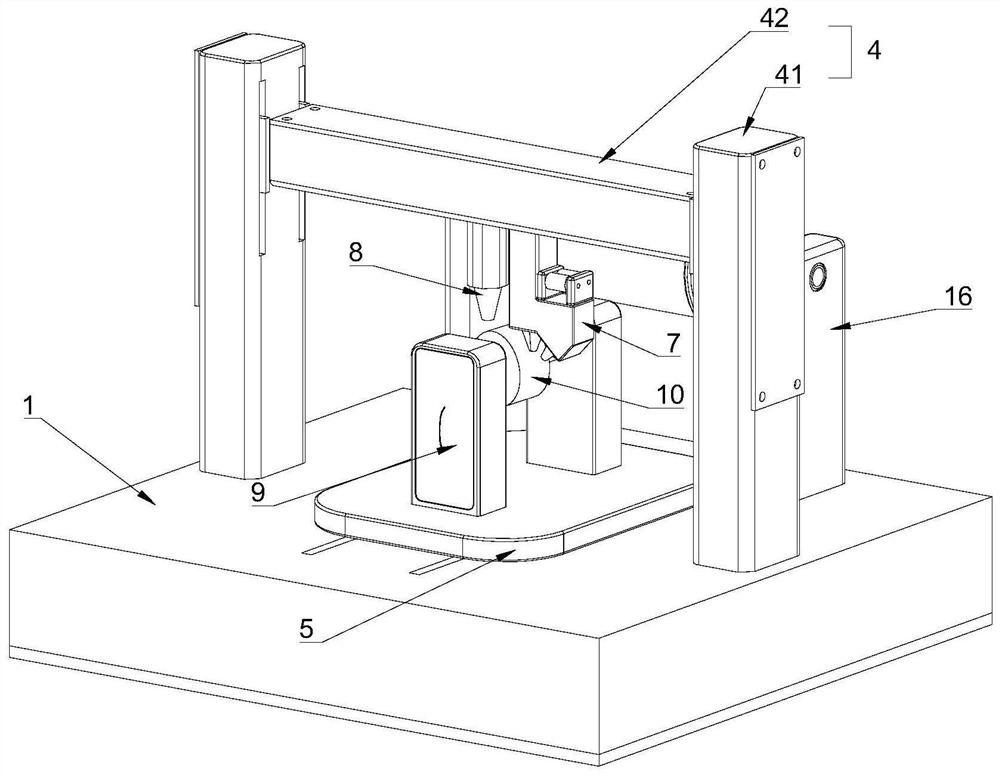

[0046] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. Unless otherwise specified, the instruments or materials used in the present invention are commercially available. The application scenarios of the present invention are: manufacturing grinding wheels, grinding wheel dressing, laser sharpening and laser dressing.

[0047] Manufacture of grinding wheels: Additive manufacturing of grinding wheels and simultaneous laser sharpening and laser dressing.

[0048] Grinding wheel dressing: directly carry out laser sharpening and shaping on the worn grinding wheel, or first partially add material to repair, and then laser sharpening and shaping can be carried out simultaneously.

[0049] Laser sharpening uses the optical system to focus the laser beam into a very small spot, and acts on the surface of the grinding wheel, which can melt and vaporize the bonding material on the local surface of th...

Embodiment 2

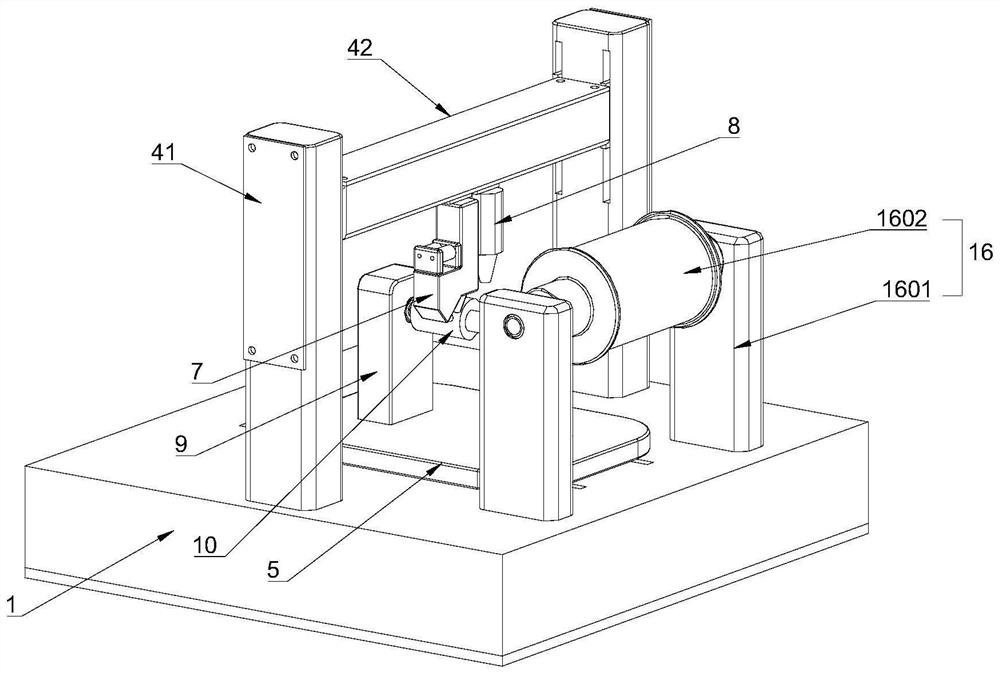

[0087] like Figures 5 to 6 As shown, the synchronous processing device for adding and subtracting materials in this embodiment is roughly the same as that in Embodiment 1, except that:

[0088] 1. The number of gantry beams 42 is two. The laser material addition module 7 and the laser material subtraction module 8 are respectively installed on the two gantry beams 42 and are driven by different horizontal driving devices 17 to move in the horizontal direction.

[0089] The movement of the X-axis (along the length direction of the first horizontal ball screw 173 ) and the Z-axis of the laser material addition module 7 and the laser material reduction module 8 are independent of each other, realizing more complex processing.

[0090] 2. Two sets of vertical driving devices 18 are installed inside the upper part of each gantry column 41 , and the two sets of vertical driving devices 18 are respectively used to drive two gantry beams 42 . The gantry column 41 is provided with in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com