Supercritical fluid auxiliary melt differential electrostatic spinning device

A supercritical fluid, melt differentiation technology, applied in textile and papermaking, filament/thread forming, filament forming processing and other directions, can solve the problem of low fiber preparation efficiency, poor mechanical properties, and low melt electrospinning fiber preparation efficiency And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

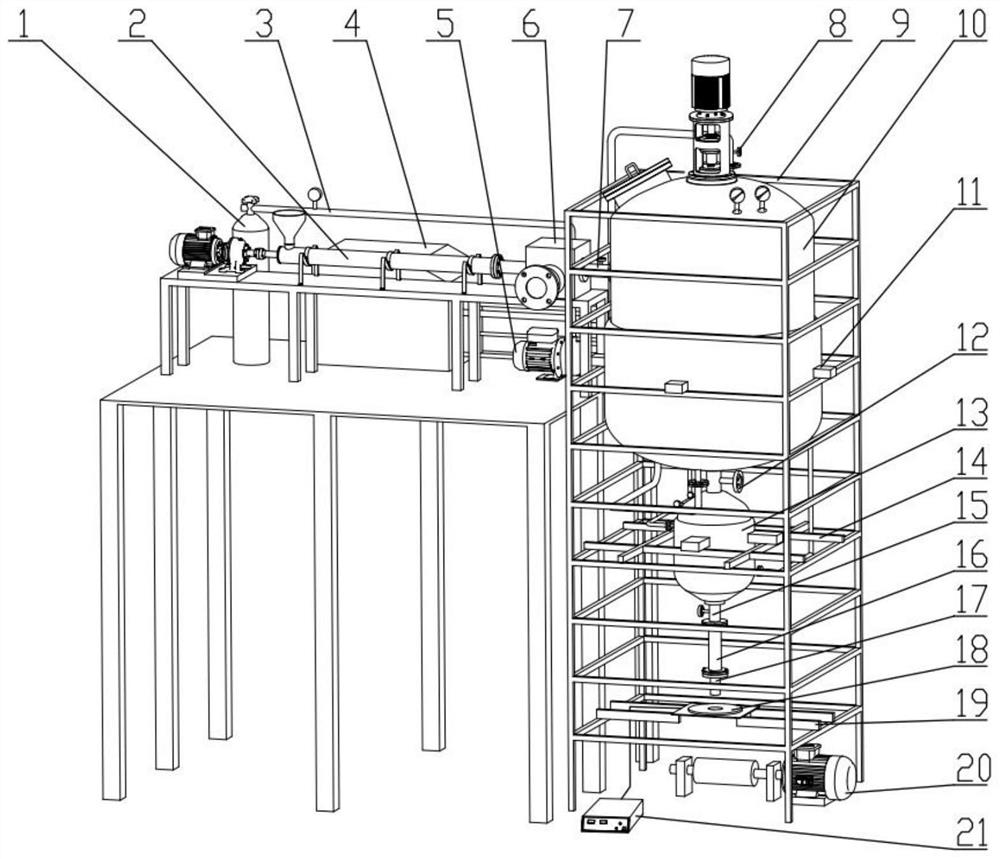

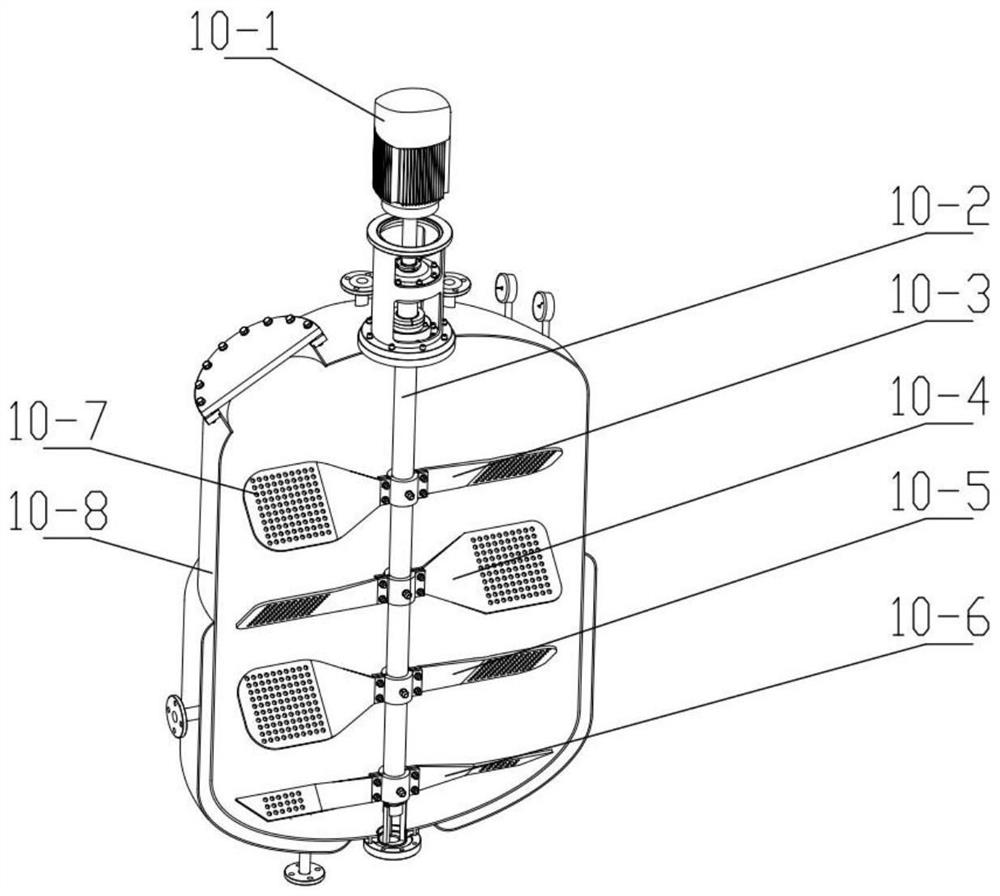

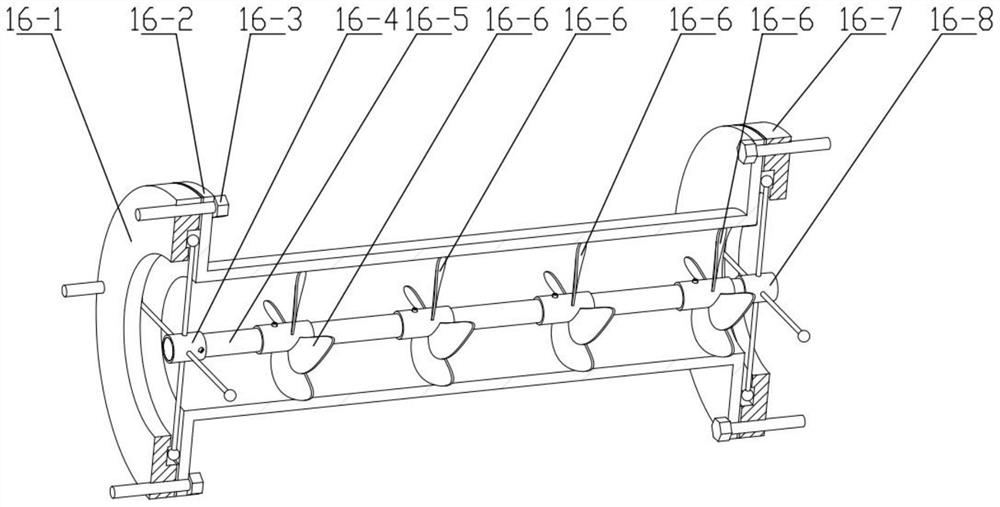

[0016] Supercritical fluid assisted melt differential electrospinning device of the present invention, such as figure 1 As shown, it consists of a feeding system, a supercritical fluid supply system, a fluid mixing system, a pressure relief system, a spinning system and a winding roll 20. The feeding system is composed of screw extruder 2, melt pump 6, flange 15 and melt inlet valve 7. The end of screw extruder 2 is connected to melt pump 6, and one end of melt inlet valve 7 is connected to melt pump. 6. The other end is connected to the high-pressure stirred tank 10. The supercritical fluid supply system is composed of a gas storage bottle 1, a pipeline 3, a booster pump 5 and a supercritical fluid inlet valve 8. The gas storage bottle 1 and the booster pump 5 are connected through a pipeline 3, and one end of the supercritical fluid inlet valve 8 is Connect the booster pump 5, and connect the other end to the high-pressure stirring tank 10. The high-pressure stirred tank 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com