Rail transit platform door protection method

A rail transit and platform door technology, which is applied in the field of rail transit, can solve the problems of easily endangering the safety of surrounding personnel, the position deviation of rail transit platform doors, and the reduction of the safety performance of rail transit platform doors, so as to increase the completeness of precipitation and reduce the weight , the effect of ensuring safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

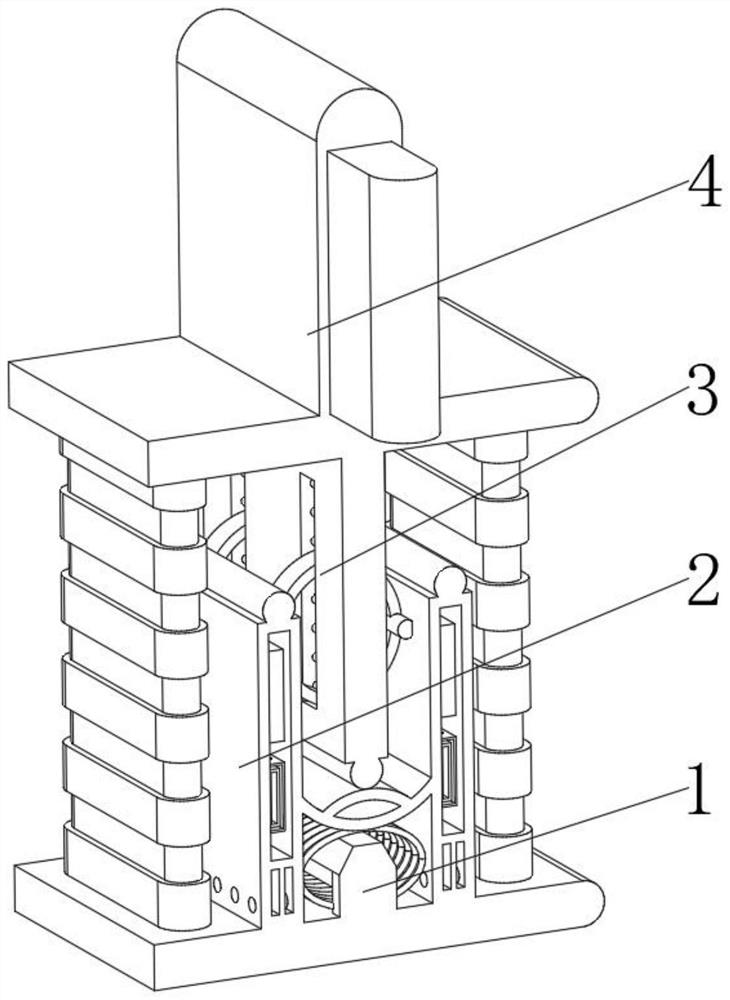

[0036] see Figure 1-5 , the present invention provides a technical solution: a rail transit platform door protection method, specifically comprising:

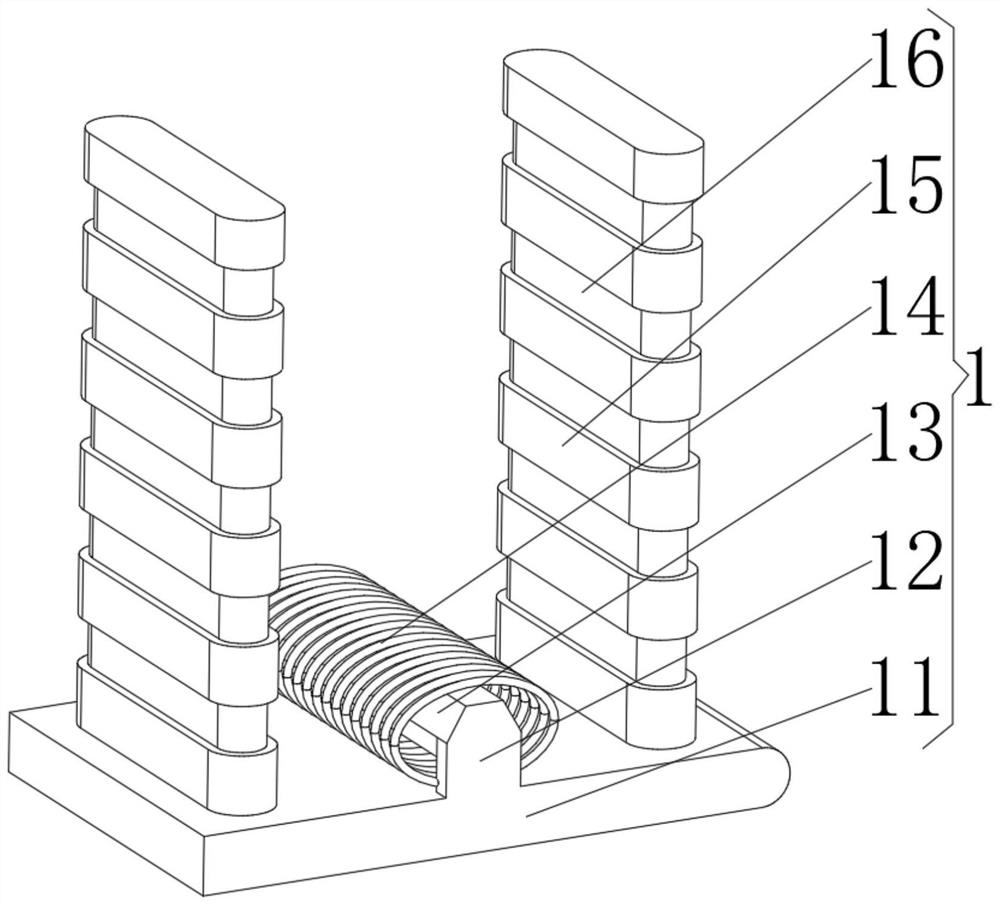

[0037] Bearing base 1, the bearing base 1 has a concave body, and a relaxation device 2 installed in the middle of the bottom of the cavity of the concave body, and a conduction device 3 installed on the top of the concave body, and installed in the middle of the side of the conduction device 3 away from the concave body The platform electric door 4 at the position, the bearing seat 1 includes:

[0038] Base plate 11, the base plate 11 has a square plate body, and a mounting frame plate 12 installed in the middle of the top of the square plate body, and a hexagonal stem 13 installed between the mounting frame plates 12, and a hexagonal stem 13 sleeved on the hexagonal plate body The current coil 14 on the outer surface of the stem 13 , the magnetic repelling blocks 15 installed on the top of the square plate and on both sides...

Embodiment 2

[0046] see Figure 1-5 On the basis of Embodiment 1, the present invention provides a technical solution: a method for protecting a rail transit platform door, comprising the following steps,

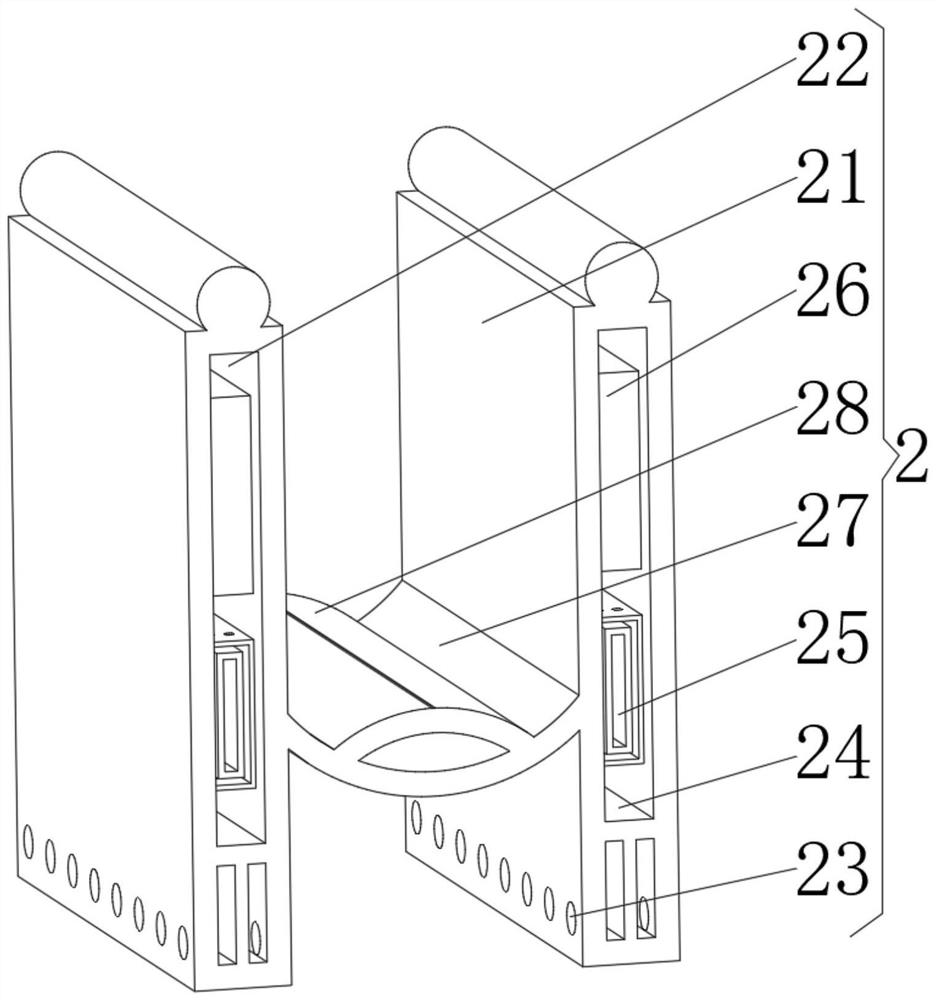

[0047] Step 1: When the platform electric door 4 is opened and closed, it generates vibration itself, which drives the conduction plate 31 to vibrate, so that the vibration is transmitted along the vertical plate 32, and cooperates with the elasticity of the arc-shaped airbag 28 to make the vertical plate 32 move vertically up and down. reciprocating motion;

[0048] Step 2: the reciprocating motion of the vertical plate 32 causes the arc-shaped power generation stack 35 and the friction column 34 to rub against each other to generate electric energy, and transmit the electric energy to the current converter 26 through the energy conducting column 36;

[0049] Step 3: The current converter 26 in the relaxation device 2 converts the electric energy to supply the T-shaped airflow pump 24...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com