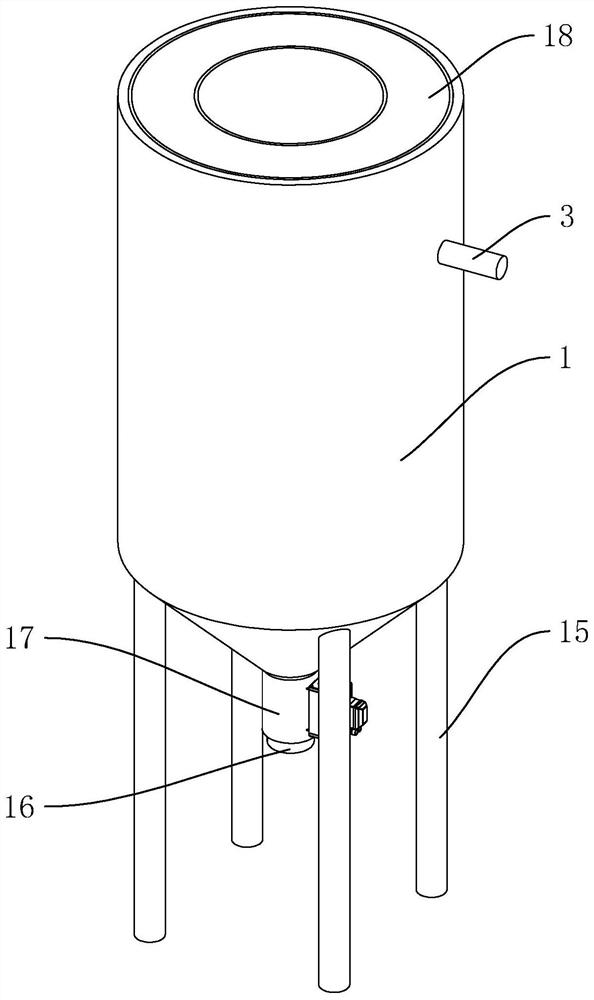

a cement storage bin

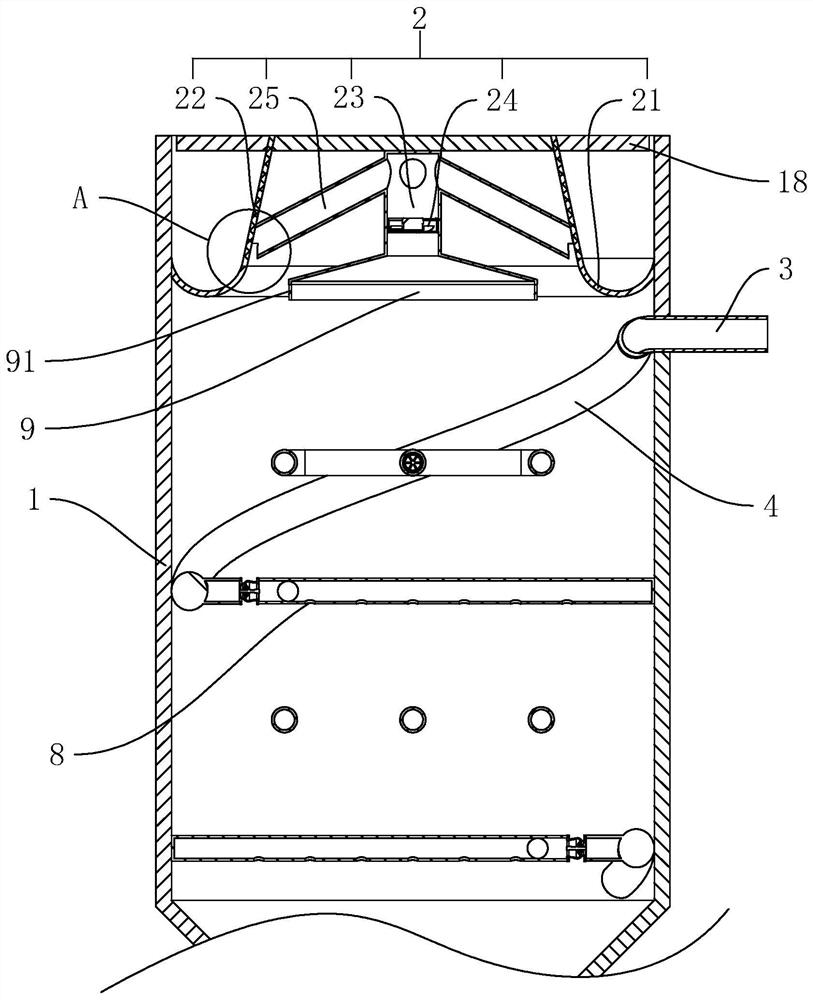

A technology for storage silos and cement, which is applied in the directions of transportation, packaging, loading/unloading, etc. It can solve the problems of cement dry powder leaking and polluting the environment, increasing the working strength of filter elements, and clogging and damage of dust removal equipment, so as to reduce working strength and avoid clogging , to reduce the effect of impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

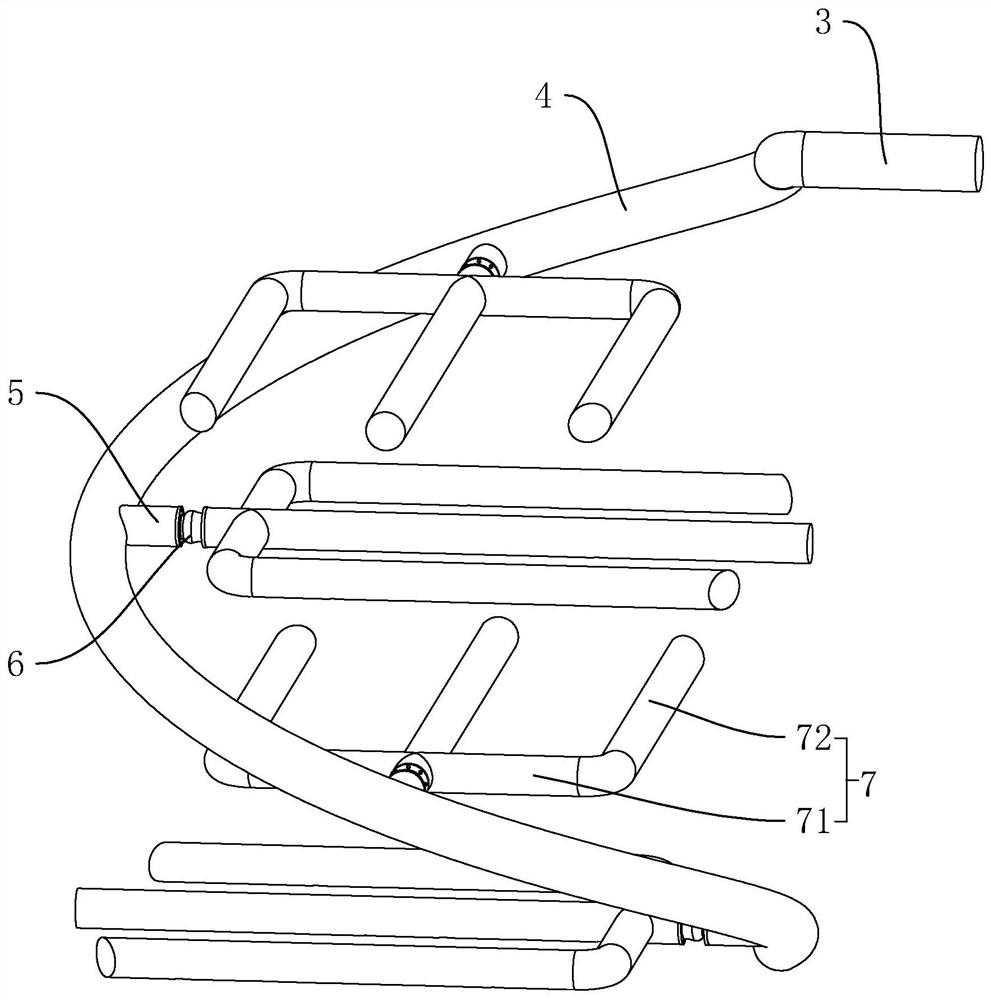

[0050] refer to Figure 5 The difference from Embodiment 1 is that the uniform discharge assembly 7 includes a branch pipe 73 horizontally connected to the material distribution pipe 5, a support rod 74 horizontally fixedly connected to the inner wall of the storage bin, and a support rod 74 arranged on the support rod 74. Distributor 75, support rod 74 is cross-shaped and arranged below branch pipe 73, branch pipe 73 is made as L-shaped, two diverter platforms 75 are fixedly connected at the center of support rod 74, and the discharge port of branch pipe 73 is vertical Arranging downwards, the discharge port of the material distribution pipe 5 is located on the vertical axis of the storage bin, and the flow diversion table 75 is configured as a conical shape, and the flow distribution table 75 is located vertically below the discharge port.

[0051] The implementation principle of this embodiment is: when transporting cement to the storage bin, the dry cement powder first ent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com