Pipe-scraping well-washing filtering device and well-washing filtering method thereof

A filtering device and scraping tube technology, which is applied to wellbore/well components, earth-moving drilling, and fluid production, etc., can solve the problems of poor adsorption effect of strong magnetic scraping device, and the adsorption capacity cannot continue to be adsorbed, so as to improve the cleanliness. and operation timeliness, increased operation safety, and low R&D and use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

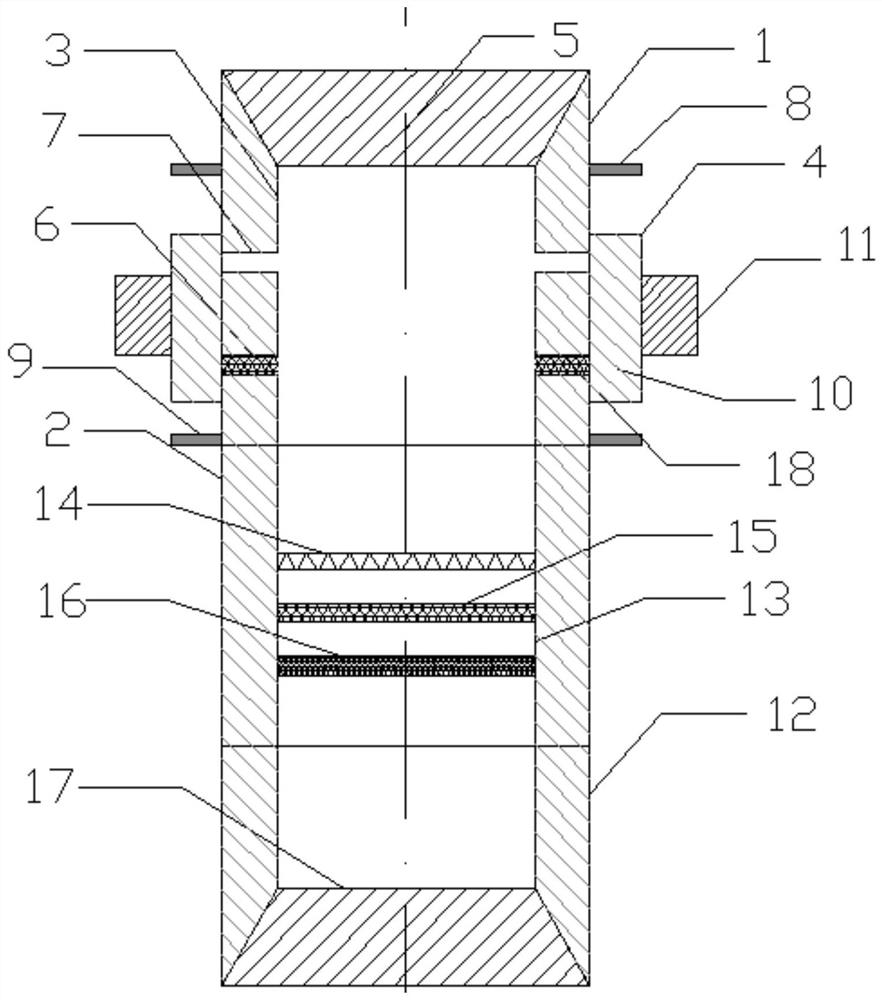

[0025] A scraper cleaning and filtering device, comprising an overflow string 1 and a filter 2, the tail end of the overflow string 1 is integrally arranged at the head end of the filter 2,

[0026] The overflow pipe string 1 includes an inner pipe string 3 and a sealing sleeve 4, a first internal thread 5 is provided on the inner wall of the head end of the inner pipe string 3, and a grouting through hole 6 is opened on the lower side wall of the inner pipe string 3, In the grouting through hole 6, a filter plate 18 for preventing impurities from entering the inner pipe string is provided, and a filtering through hole 7 is opened on the side wall of the inner pipe string 3 above the grouting through hole 6, and the sealing sleeve 4 is slidably arranged on the on the outer wall of the inner pipe column 3, so as to realize the purpose of slidingly opening / closing the grouting through hole 6 and the filtering through hole 7;

[0027] The tail end of the filter 2 is installed wit...

Embodiment 2

[0029] On the basis of the first embodiment, an upper stop step 8 and a lower stop step 9 are sequentially provided on the outer wall of the inner pipe string 3 from top to bottom, so as to achieve the purpose of limiting the sliding displacement of the sealing sleeve 4 .

[0030] The sealing sleeve 4 includes a slider 10 and a sealing rubber 11. The slider 10 is slidably installed on the outer wall of the inner pipe string 3, and a sealing rubber 11 is arranged on the outer side of the slider 10 to realize the sealing between the outer wall of the inner pipe string 3 and the sleeve. The purpose of the annulus between the inner walls of the tube.

[0031] The number of grouting through holes 6 is three, and the angle between adjacent grouting through holes 6 is 120°.

[0032] The number of filtering through-holes 7 is three, and the included angle between adjacent filtering through-holes 7 is 120°.

[0033] The mesh number of the upper layer filter screen 14 is 50 orders, the...

Embodiment 3

[0035] On the basis of the second embodiment, the head end of the inner pipe string 3 is connected with the outer thread of the strong magnetic scraper through the first inner thread 5 .

[0036] The tail end of the one-way valve 12 is connected with the roller cone bit through the second internal thread 17 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com