Asphalt adhesive force testing device for road construction

A road construction and testing device technology, applied in the direction of measuring devices, mechanical devices, instruments, etc., can solve the problems such as the inability to adjust the extrusion force of the testing device, the inability to change the part of the asphalt extrusion, and the relative movement trend of the briquetting block.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] Hereinafter, the present invention will be described in detail with reference to the drawings and examples. It should be noted that, in the case of no conflict, the embodiments of the present invention and the features in the embodiments can be combined with each other.

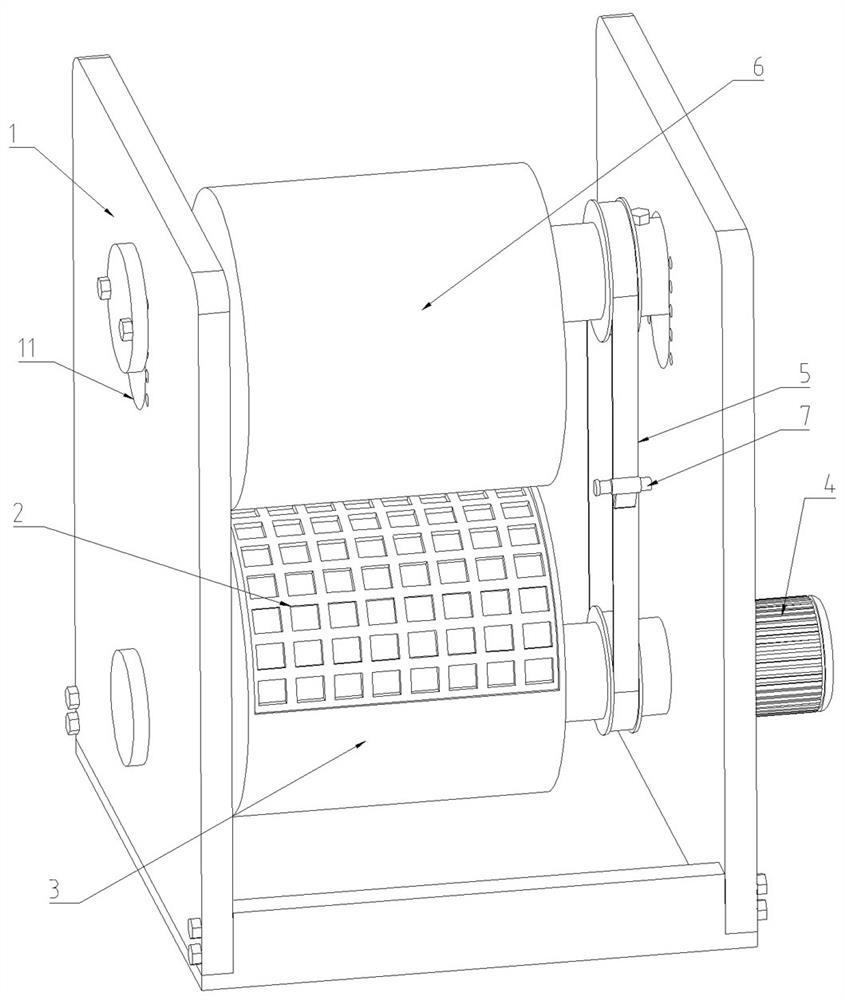

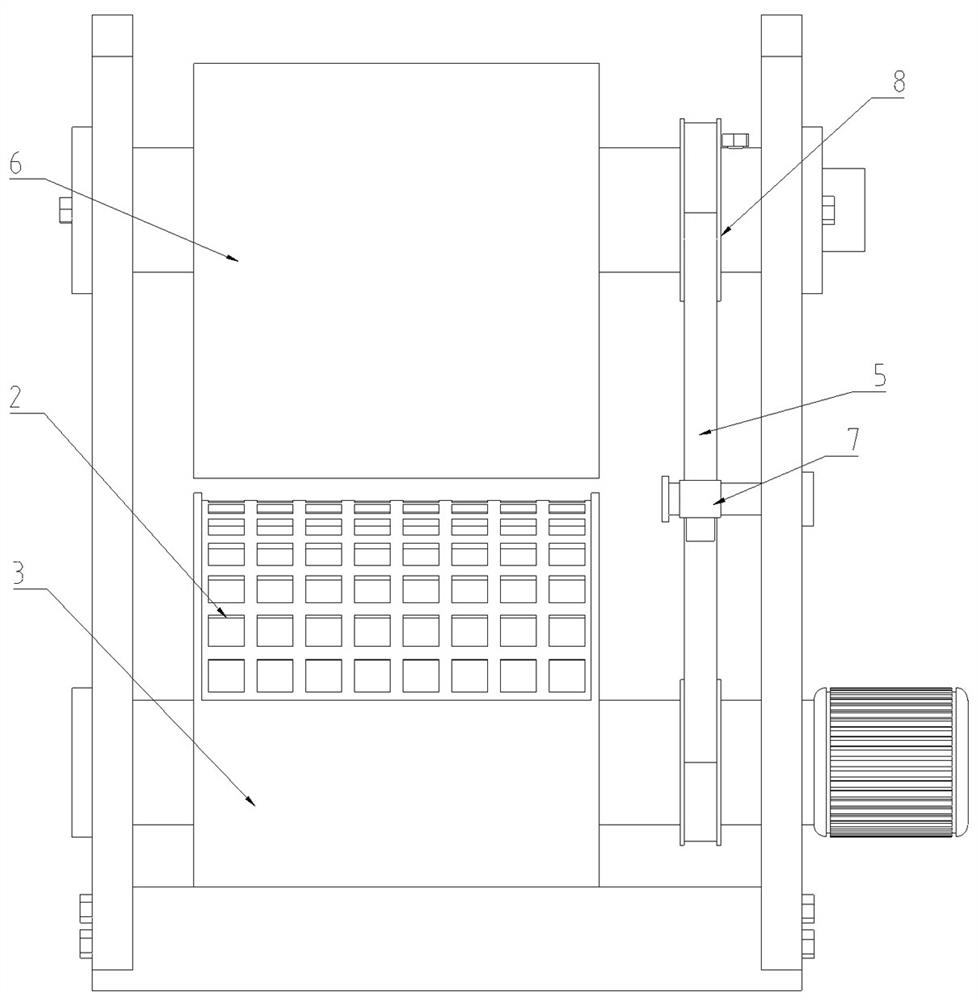

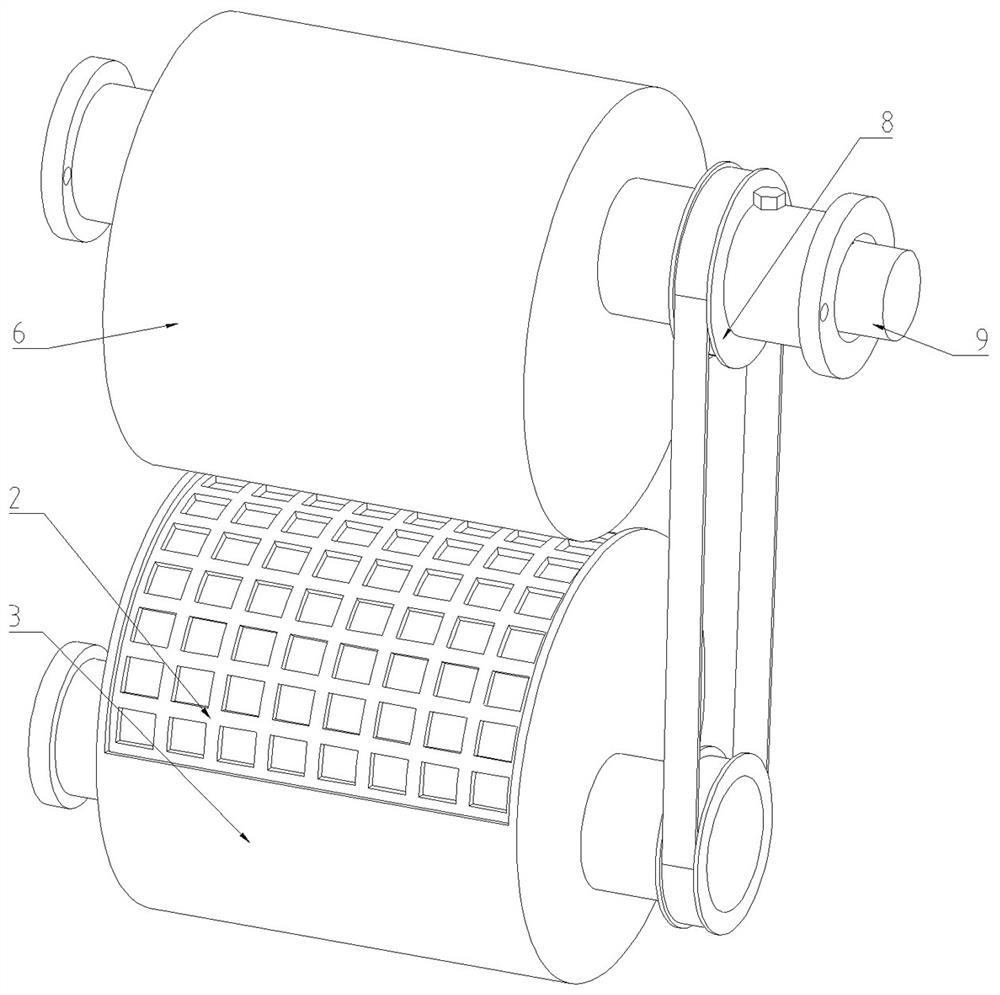

[0033] Such as Figure 1-10 A road construction asphalt adhesion testing device is shown, comprising: a support module 3, which can be rotated or rotated to a fixed required position for supporting the test sample 2 laid on its surface, and the test sample 2 and the support module 3 The conforming track of the shape is a curved surface; the rolling module 6 is used to roll the test sample 2 laid on the support module 3 .

[0034] When the present invention was implemented, the implementation points were as follows:

[0035] 1, the present invention utilizes support module 3, rolling module 6 rolling, makes the test model 2 that lays on the support module 3 be squeezed, obtains the result of adhesion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com