Opening awl with positioning needle assembly for field spinal surgery

A technology for positioning needles and components, which is applied in the fields of surgery, medical science, bone drill guidance, etc., can solve the problems of difficult operation accuracy, high operation risk, and lengthy time, and achieves easy operation, guarantees mechanical strength, and improves operation success. rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

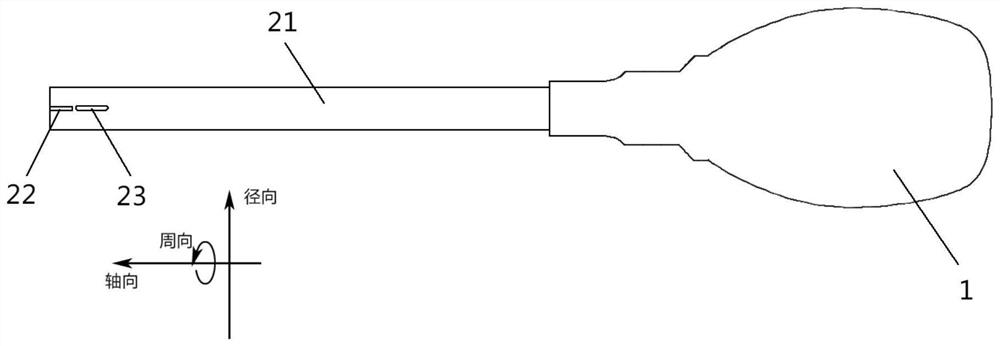

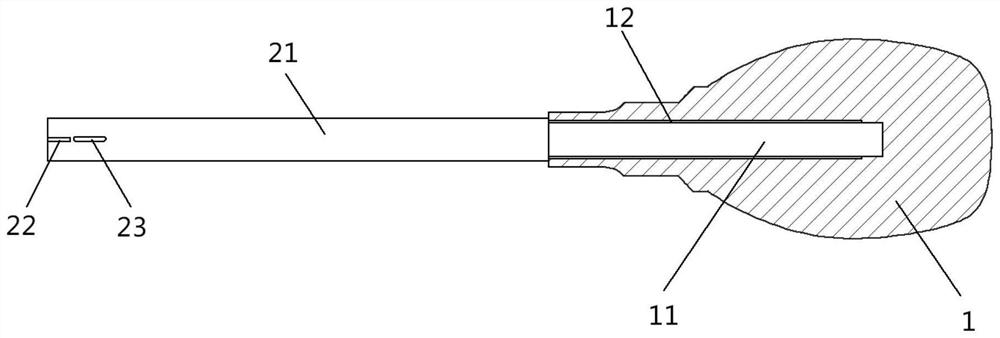

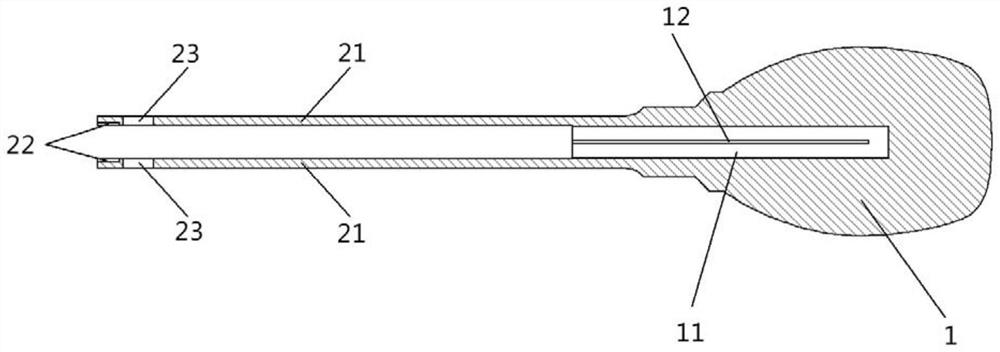

[0073] This embodiment provides a kind of open circuit cone, such as Figure 1 to Figure 14 As shown, it includes a handle 1 and an open circuit assembly 3, and the handle 1 and the open circuit assembly 3 are connected through a support assembly 2;

[0074] The support assembly 2 includes a pair of support rods 21 symmetrically arranged parallel to the axial direction, and the bottom end of the support rods 21 is fixedly connected to the end of the handle 1;

[0075] The open-circuit assembly 3 includes a cone rod 32 and a rotating base 33, the top of the cone rod 32 is fixedly connected with a cone head 31, and the bottom end of the cone rod 32 is fixedly mounted on the top of the rotating base 33; The positioning pin placement bin 33-8 is set coaxially with the taper rod 32;

[0076] The middle part of the side wall of the rotating base 33 is symmetrically provided with a pair of rotating support rods 33-2, and the rotating supporting rods 33-2 are movably installed on the...

Embodiment 2

[0104] This embodiment provides a positioning pin assembly, such as Figure 15 to Figure 16 As shown, it includes a first positioning pin 51 and a second positioning pin 52;

[0105] The first positioning needle 51 includes a first needle handle 51-1 and a first needle body 51-2, the top end of the first needle handle 51-1 is fixedly connected with a first connecting body 51-3, and the first needle body 51-2 The bottom end passes through the first connecting body 51-3 and is fixedly connected with the first needle handle 51-1;

[0106] The second positioning needle 52 includes a second needle handle 52-1 and a second needle body 52-2, the top of the second needle handle 52-1 is fixedly connected with a second connecting body 52-3, and the second needle body 52-2 The bottom end passes through the second connecting body 52-3 and the second needle handle 52-1 until the bottom end of the second needle handle 52-1 is fixedly connected to the second needle handle 52-1.

[0107] In...

Embodiment 3

[0110] This embodiment provides a kind of open circuit cone, such as Figure 17 to Figure 21 As shown, on the basis of the opening cone in embodiment 1, the open circuit cone adds a positioning pin assembly 5, the positioning pin assembly 5 is installed in the positioning pin placement warehouse 33-8, and the positioning pin assembly 5 adopts the positioning pin in embodiment 2 components.

[0111] During use, the first needle handle 51-1 and or the second needle handle 52-1 are installed in the positioning needle placement bin 33-8, and the bottom ends of the first needle handle 51-1 and or the second needle handle 52-1 The positioning needle push-out plate 33-11 is in contact with each other, and the outer contour of the bottom end of the first needle handle 51-1 fits with the inner side wall of the positioning needle placement warehouse 33-8, and the outer contour of the bottom end of the second needle handle 52-1 also fits The inner side wall of the positioning pin placem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com