Eye-moistening glasses made of reverse osmosis membrane material and manufacturing method of eye-moistening glasses

A technology of reverse osmosis membrane and production method, which is applied in the field of design and production of special glasses, which can solve the problems of easy water seepage, large size, blocking light on both sides and heavy weight, etc., and achieves beautiful appearance, does not block left and right sight lines, and light frame body Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

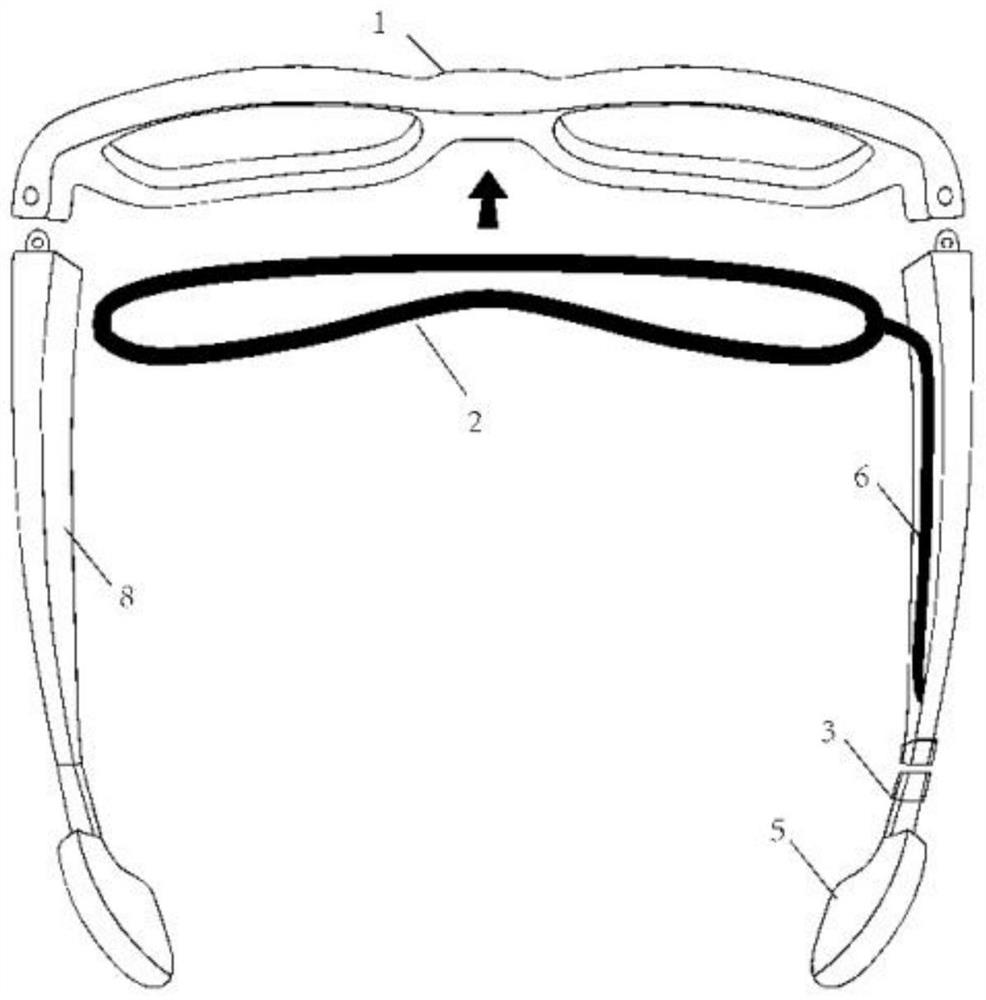

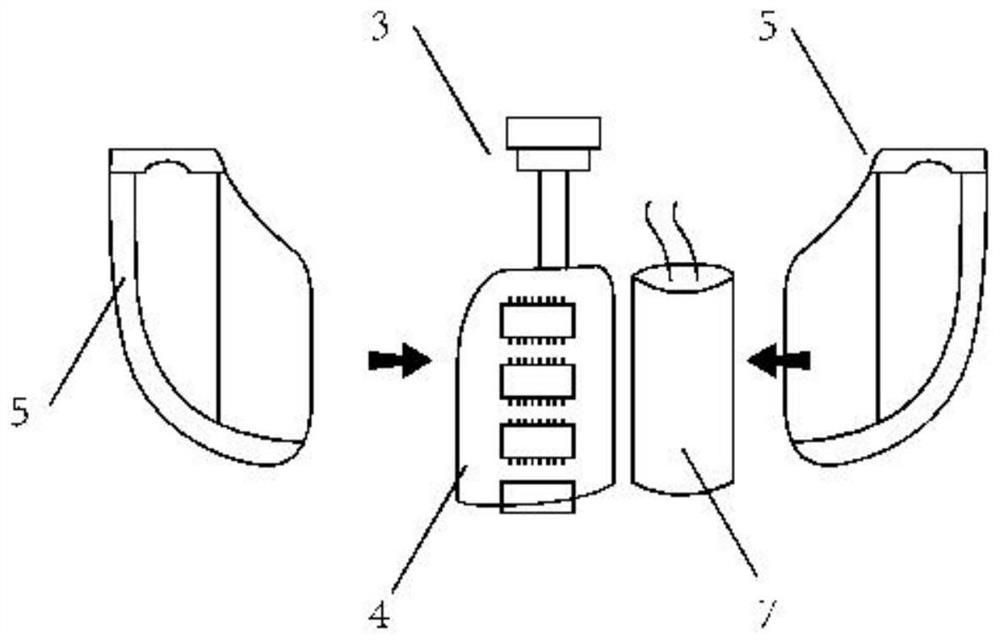

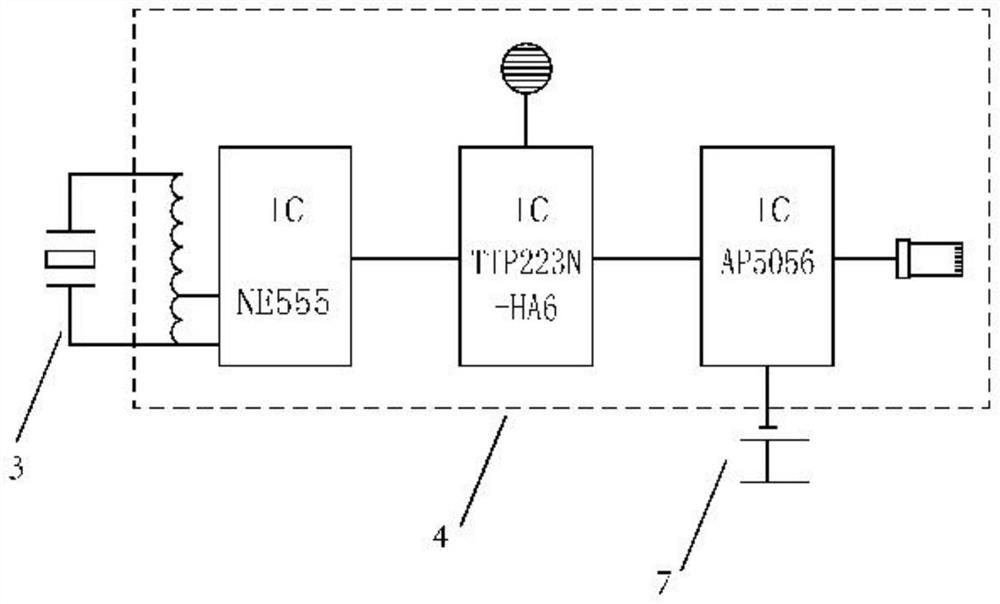

[0041] An eye-moistening glasses made of reverse osmosis membrane material includes a frame precursor 1, a reverse osmosis membrane material rear body 2, an ultrasonic pressure pump 3, an ultrasonic driving circuit board 4, a pressure pump housing 5, a silicone hose 6, and a driving power supply 7. The mirror leg 8, the ultrasonic pressure pump 3, the ultrasonic drive circuit board 4 and the driving power supply 7 are combined and installed in the pressure pump housing 5, and the pressure pump housing 5 is socketed and installed at the tail of the mirror leg 8; the reverse osmosis The back body 2 of film material is installed behind the front body 1 of the picture fra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com