Lithium battery cell slurry stirring equipment

A technology of stirring equipment and lithium batteries, which is applied in the direction of mixer accessories, mixers with rotating stirring devices, mixers, etc., can solve the problems of battery quality degradation, uneven slurry, etc., to ensure quality, mix uniformly, and avoid stirring uneven effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific embodiments.

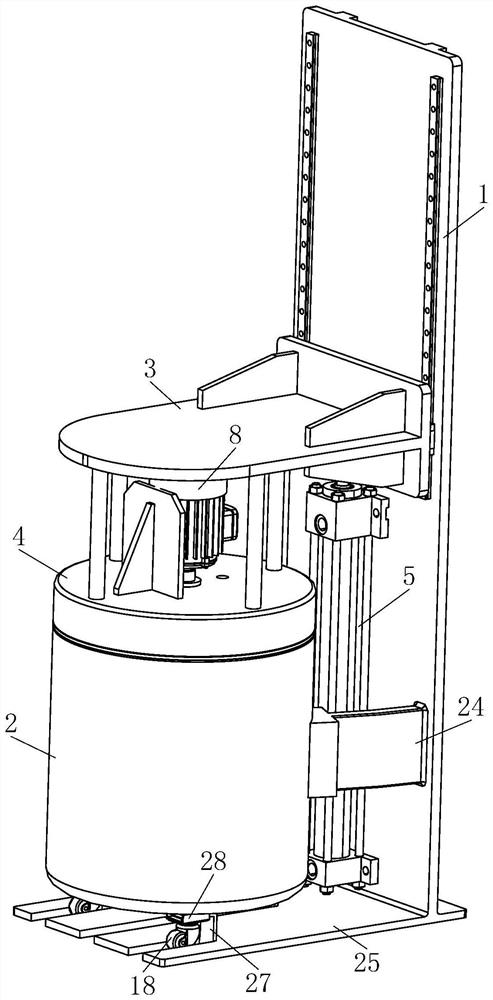

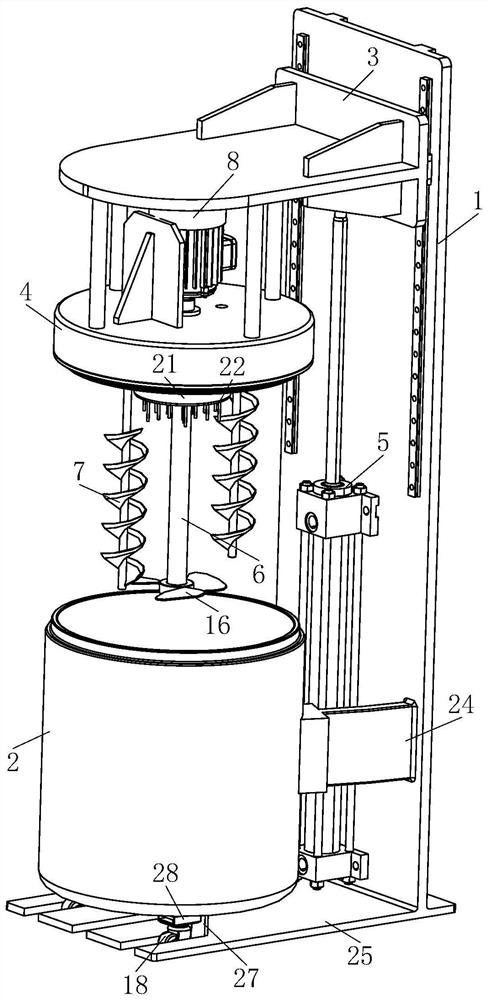

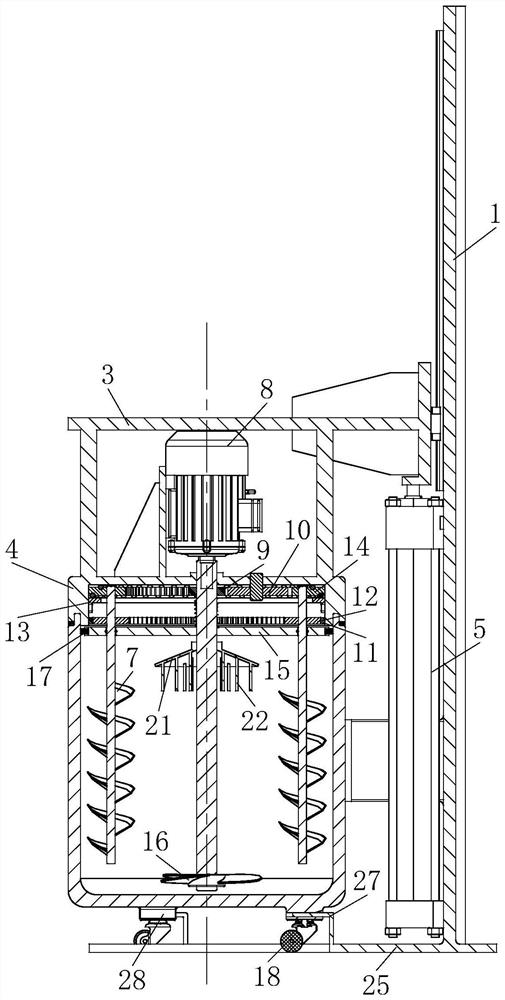

[0042] Such as Figure 1 to Figure 9As shown, a lithium battery cell slurry mixing equipment includes a fixed frame 1, a mixing drum 2, a movable frame 3, an upper cover 4, a hydraulic cylinder 5, a main shaft 6, a screw frame 7 and power components; the fixed frame 1 One side of the slide rail is symmetrically provided with a slide rail, and the slide rail is fixedly connected with the fixed frame 1; one side of the slide rail is provided with a slide block; the slide block is slidingly connected with the slide rail; the slide block One side of the fixed frame 1 is provided with the movable frame 3; the movable frame 3 is fixedly connected with the slider; one side of the fixed frame 1 is provided with the hydraulic cylinder 5; the hydraulic cyli...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap