Lime milk carbonization reaction furnace for building calcium carbonate extraction

A carbonization reaction and calcium carbonate technology, applied in the field of reaction furnaces, can solve the problems such as the inability to fully react with milk of lime and carbon dioxide, and the quantitative feeding of milk of lime, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

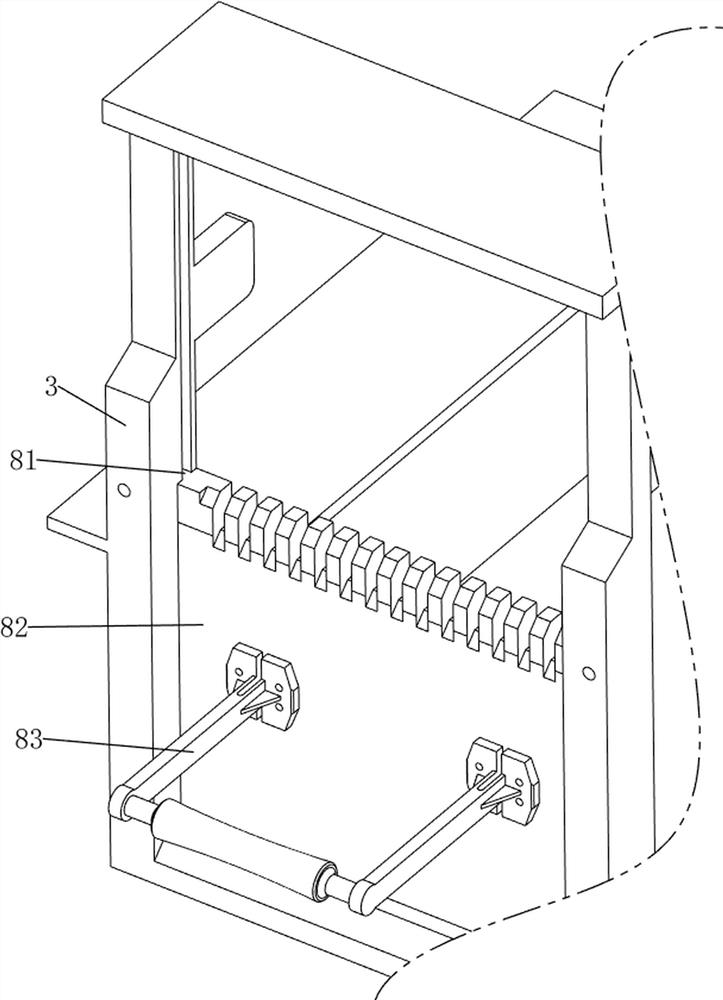

[0037] A lime milk carbonization reaction furnace for building calcium carbonate extraction, such as Figure 1-3 As shown, it includes a support frame 1, a main frame 2, a grinding frame 3, a grinding plate 4, a first spring 5, a first pressing rod 6, an unloading mechanism 7 and a retrieving mechanism 8, and the bottom of the main frame 2 is symmetrically arranged. There is a support frame 1, a grinding frame 3 is provided at the inner bottom of the main frame 2, and two first pressing rods 6 are provided slidingly on the right side of the main frame 2, and a grinding plate 4 is connected between the left sides of the two first pressing rods 6, The grinding plate 4 is in sliding contact with the inner bottom of the grinding frame 3, two first springs 5 are connected between the grinding plate 4 and the main frame 2, the main frame 2 is provided with an unloading mechanism 7, and the front side of the grinding frame 3 is provided with a take-off Material mechanism 8.

[003...

Embodiment 2

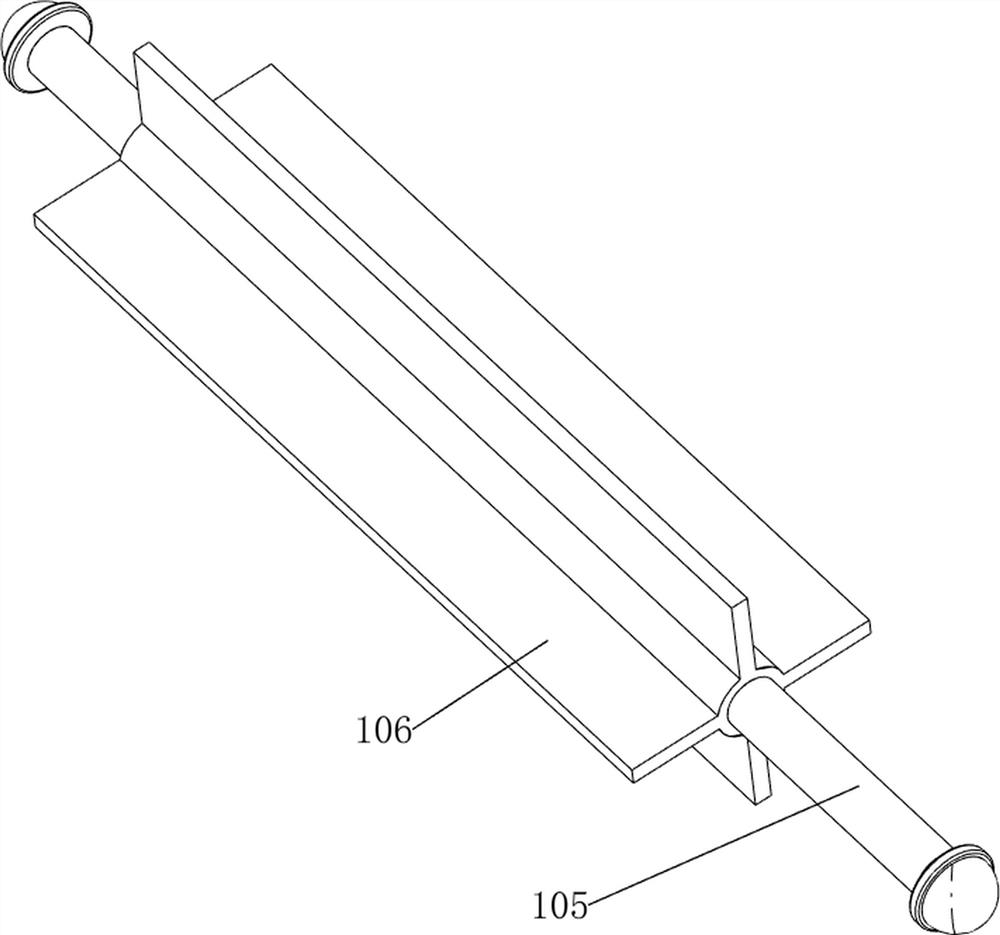

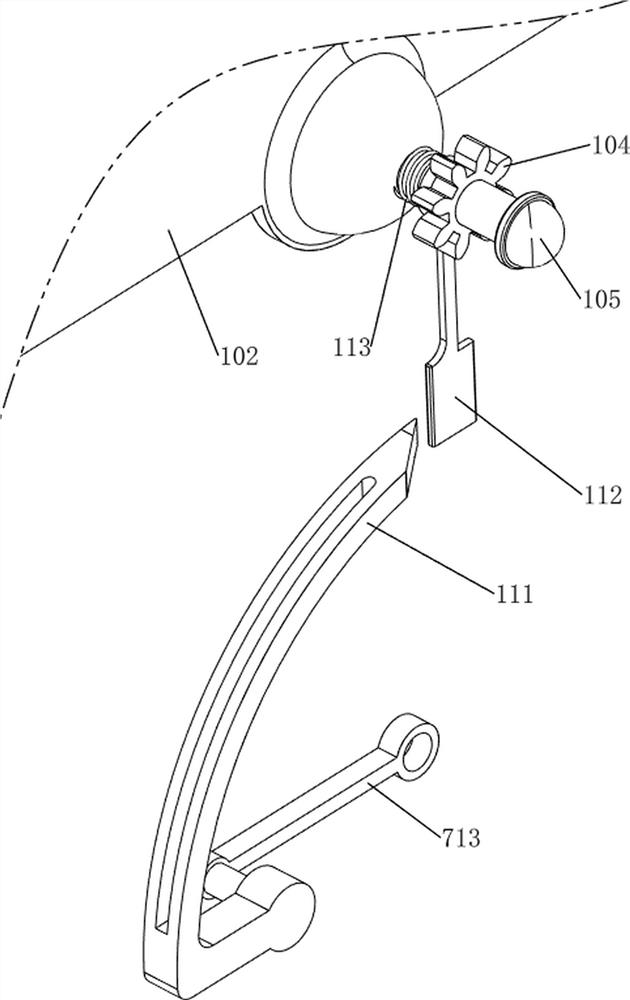

[0040] On the basis of Example 1, such as Figure 4-8As shown, the unloading mechanism 7 includes a first fixed column 71, a motor 72, a flat belt 73, a first rotating shaft 74, a first missing gear 75, a second rotating shaft 76, a first spur gear 77, a block 78, a third Rotating shaft 79, the second spring 710, the second fixed column 711, the torsion spring 712, the first rotating rod 713, the curved slide rail 714, the reaction frame 715 and the supporting plate 716, the upper side of the main frame 2 right is provided with a first The fixed column 71 is provided with a motor 72 on the first fixed column 71, the output shaft of the motor 72 is connected with the main frame 2 in a rotational manner, and the middle of the right part of the main frame 2 is rotatably provided with a first rotating shaft 74, the first rotating shaft 74 and the motor 72 Belt pulleys are provided on the output shafts of the belt pulleys, flat belts 73 are connected between the two pulleys, the fi...

Embodiment 3

[0045] On the basis of Example 2, such as Figure 9-16 As shown, the gas injection mechanism 9 is also included, and the gas injection mechanism 9 includes a third fixed column 91, an air reservoir 92, an air delivery pipe 93, a switch 94, a second pressing rod 95, a connecting rod 96 and a third spring 97, and the grinding The lower side of the rear part of the frame 3 is connected with a third fixed column 91, and the third fixed column 91 is provided with an air storage tank 92. An air delivery pipe 93 is connected between the front side of the air storage tank 92 and the grinding frame 3, and the top of the air delivery pipe 93 is slidingly provided with The switch 94 is connected with the third spring 97 between the switch 94 and the gas delivery pipe 93, the rear side of the first rotating rod 713 is connected with the second depression bar 95, and the left and right sides of the switch 94 are connected with the connecting rod 96.

[0046] When the first rotating rod 713...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap