Pouring machine provided with protection mechanism and used for cement culvert pipe manufacturing and pouring method

A protective mechanism and cement technology, applied in the direction of manufacturing tools, ceramic molding machines, reinforced molding, etc., can solve the problems of inconvenient disassembly and fixation of culvert molds, lack of shielding protection functions, complex operations, etc., to achieve strong practicability and reduce workload , avoid the effect of splashing and overflowing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

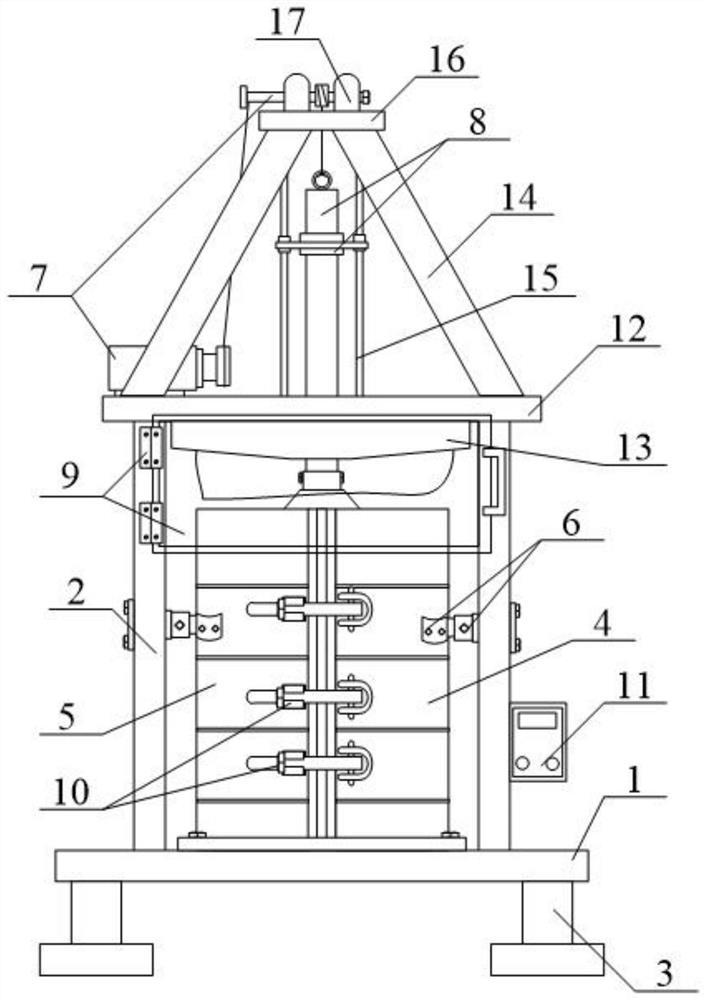

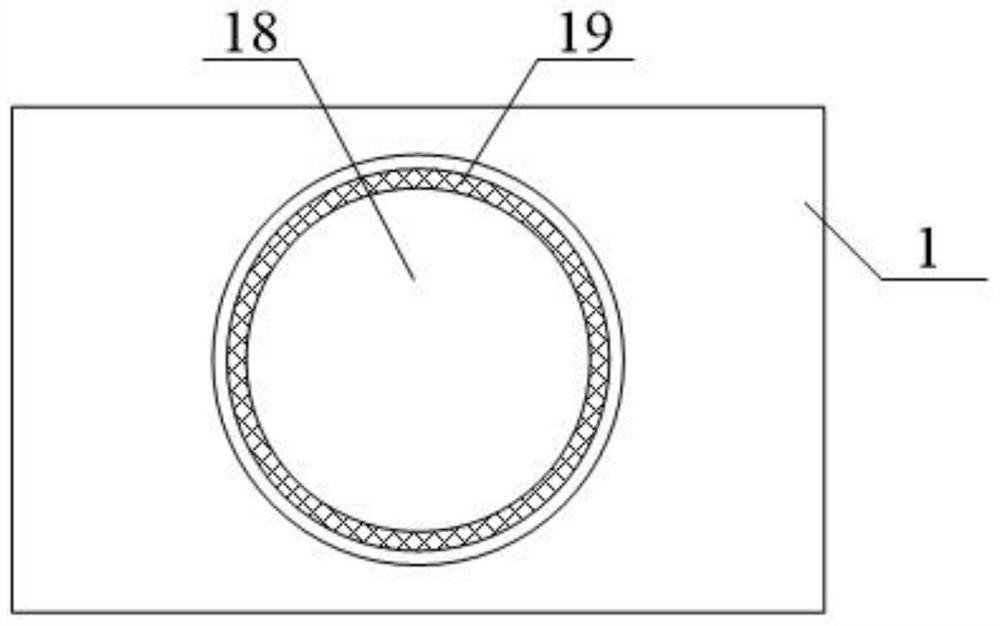

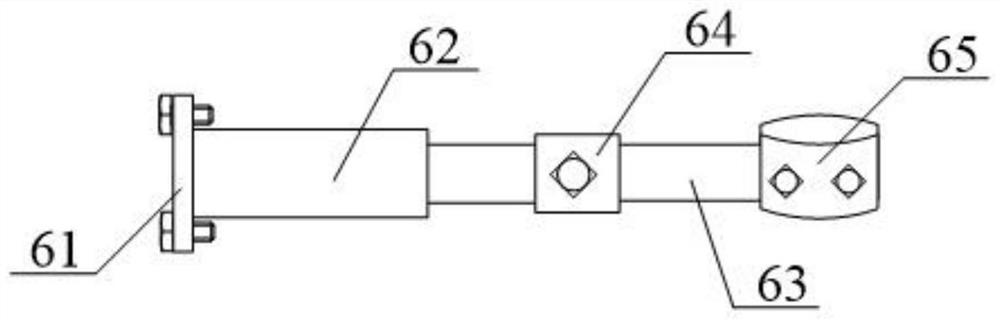

[0056] as attached figure 1 to attach figure 2 As shown, the present invention provides a pouring machine and pouring method for the manufacture of cement culvert pipes with a protective mechanism, including a support base plate 1, a support vertical beam 2, a support foot 3, a right mold blocking plate 4, and a left mold Cylinder plate 5, mold splint opening and closing handle assembly 6, lifting and hanging wire mechanism 7, pouring centrifugal smearing plate assembly 8, folding protective baffle assembly 9, mold plate clamping and locking assembly 10, electrical control box 11, top support Frame 12, cement material guide cylinder 13, top slanting beam 14, limit slide bar 15, top support 16, bearing seat 17, inner shaped bottom hole 18 and culvert steel frame insert 19, the support vertical beam 2 Bolts are respectively connected to the upper four corners of the support base plate 1; the support feet 3 are respectively welded to the lower four corners of the support base p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com