Treatment system and treatment method for sticky substance flushing wastewater

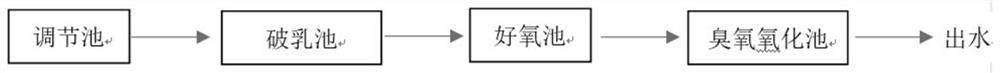

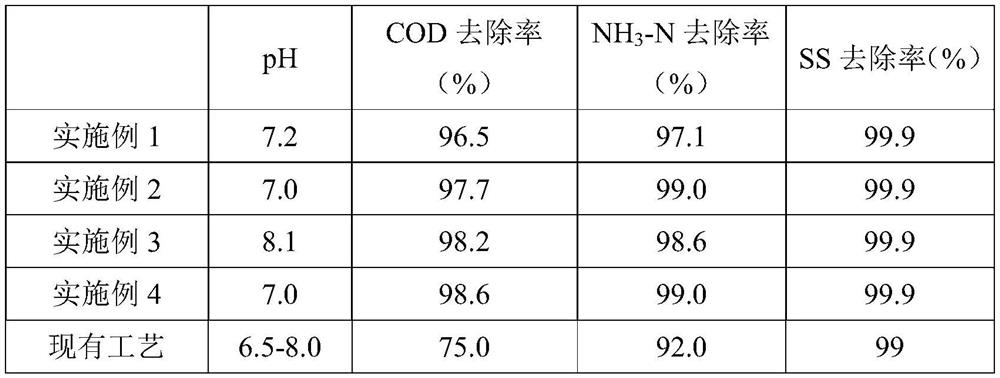

A treatment method and technology of a treatment system are applied in the treatment field of the above-mentioned treatment system, which can solve the problems of unstable treatment effect, complicated procedures and long treatment time, and achieve the effect of shortening wastewater treatment time, good treatment effect and short treatment time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The treatment method of sticky matter flushing waste water of the present invention, comprises the steps:

[0022] (1) The wastewater enters the regulating tank, the hydraulic retention time is 30 minutes, and the temperature in the tank is 30°C;

[0023] (2) The waste water after the balanced adjustment of water quantity and water quality enters the demulsification tank, and the demulsification reaction is carried out in the demulsification tank, wherein, the dosage of the demulsifier is 0.9% of the waste water quality, the reaction pH is controlled at 5.0, and the reaction time is controlled In 5 minutes; after the demulsification reaction, add flocculation and sedimentation agent, the dosage of PAM is 0.001% of the waste water quality, the reaction pH is controlled at 7.5, and the precipitation time is controlled at 4h;

[0024] (3) Pass the upper liquid into the aerobic tank, the dissolved oxygen in the aerobic tank is controlled at 3mg / L, the temperature is 35°C, a...

Embodiment 2

[0027] The treatment method of sticky matter flushing waste water of the present invention, comprises the steps:

[0028] (1) Wastewater enters the regulating tank, the hydraulic retention time is 30 minutes, and the temperature in the tank is 35 °C;

[0029] (2) The waste water after the balanced adjustment of water quantity and water quality enters the demulsification tank, and the demulsification reaction is carried out in the demulsification tank, wherein, the dosage of the demulsifier is 0.9% of the waste water quality, the reaction pH is controlled at 5.0, and the reaction time is controlled In 5 minutes; after the demulsification reaction, add flocculation and sedimentation agent, the dosage of PAM is 0.001% of the waste water quality, the reaction pH is controlled at 7.5, and the precipitation time is controlled at 4h;

[0030] (3) Pass the upper liquid into the aerobic tank, the dissolved oxygen in the aerobic tank is controlled at 5mg / L, the temperature is 38°C, and ...

Embodiment 3

[0033] The treatment method of sticky matter flushing waste water of the present invention, comprises the steps:

[0034] (1) Wastewater enters the regulating tank, the hydraulic retention time is 30 minutes, and the temperature in the tank is 35 °C;

[0035] (2) The waste water after the balanced adjustment of water quantity and water quality enters the demulsification tank, and the demulsification reaction is carried out in the demulsification tank, wherein, the dosage of the demulsifier is 1.2% of the waste water quality, the reaction pH is controlled at 6.0, and the reaction time is controlled In 10 minutes; after the demulsification reaction, add flocculation and sedimentation agent, the dosage of PAM is 0.003% of the waste water quality, the reaction pH is controlled at 8.5, and the precipitation time is controlled at 8 hours;

[0036] (3) Pass the upper liquid into the aerobic tank, the dissolved oxygen in the aerobic tank is controlled at 5mg / L, the temperature is 38°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com