Preparation method of digital metal surface rock plate

A metal surface, digital technology, applied in the field of preparation of digital metal surface slate, can solve the problem of low strength, and achieve the effect of good flatness and density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

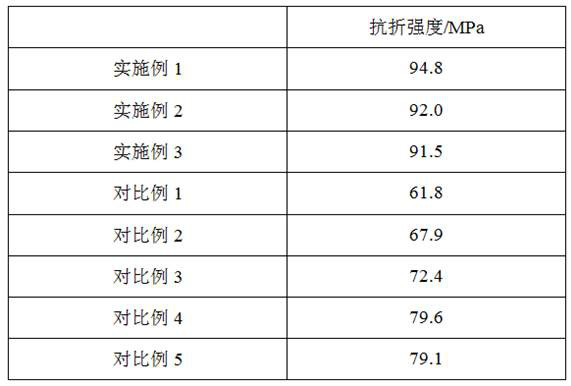

Examples

Embodiment 1

[0032] A method for preparing a digital metal surface rock plate, comprising the following steps:

[0033] The green body is fed into the ceramic digital printer, and the bottom glaze is printed by inkjet (the application amount is 150g / m 2 ), digital metal glaze (application amount is 200g / m 2 );

[0034] Send it into a kiln for sintering at 1450°C for 40 minutes, and cool to obtain the digital metal surface rock plate.

[0035] The viscosity of the digital metal glaze is 102mPa·s (at 25°C).

[0036] The digital metal surface slab is prepared by inkjet printing bottom glaze and digital metal glaze on the body, and sintered. The metal surface is formed by printing digital metal glaze. By controlling the digital metal glaze The viscosity of the material is 60~150mPa·s (25°C), which can be evenly coated and leveled during the printing process, and will not be deformed during the sintering process, so it has good flatness and density.

[0037] The bottom glaze is prepared fro...

Embodiment 2

[0049] A method for preparing a digital metal surface rock plate, comprising the following steps:

[0050] The green body is fed into the ceramic digital printer, and the bottom glaze is printed by inkjet (the application amount is 150g / m 2 ), digital metal glaze (application amount is 200g / m 2 );

[0051] Send it into a kiln for sintering at 1450°C for 40 minutes, and cool to obtain the digital metal surface rock plate.

[0052] The viscosity of the digital metal glaze is 90mPa·s (at 25°C).

[0053] The bottom glaze is prepared from the following raw materials in parts by weight: 0.5 parts of defoamer, 2 parts of surfactant, 4 parts of dispersant, 20 parts of kaolin, 10 parts of quartz stone, 5 parts of alumina, 2 parts of zirconia, 8 parts Parts of calcium silicate, 48.5 parts of solvent.

[0054] The surfactant in the bottom glaze is sodium dodecyl diphenyl ether disulfonate, the defoamer in the bottom glaze is tributyl phosphate, and the dispersant in the bottom glaze ...

Embodiment 3

[0064] A method for preparing a digital metal surface rock plate, comprising the following steps:

[0065] The green body is fed into the ceramic digital printer, and the bottom glaze is printed by inkjet (the application amount is 150g / m 2 ), digital metal glaze (application amount is 200g / m 2 );

[0066] Send it into a kiln for sintering at 1450°C for 40 minutes, and cool to obtain the digital metal surface rock plate.

[0067] The viscosity of the digital metal glaze is 125mPa·s (at 25°C).

[0068] The bottom glaze is prepared from the following raw materials in parts by weight: 0.5 parts of defoamer, 2 parts of surfactant, 4 parts of dispersant, 20 parts of kaolin, 10 parts of quartz stone, 5 parts of alumina, 2 parts of zirconia, 8 parts Parts of calcium silicate, 48.5 parts of solvent.

[0069] The surfactant in the bottom glaze is sodium dodecyl diphenyl ether disulfonate, the defoamer in the bottom glaze is tributyl phosphate, and the dispersant in the bottom glaze...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com