Polycarbonate composition for 3D printing as well as preparation method and application thereof

A polycarbonate, 3D printing technology, applied in the direction of additive processing, etc., can solve the problems of affecting the printing effect, unable to exert the performance characteristics of graphene, and easy to form holes in the composite material wire.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

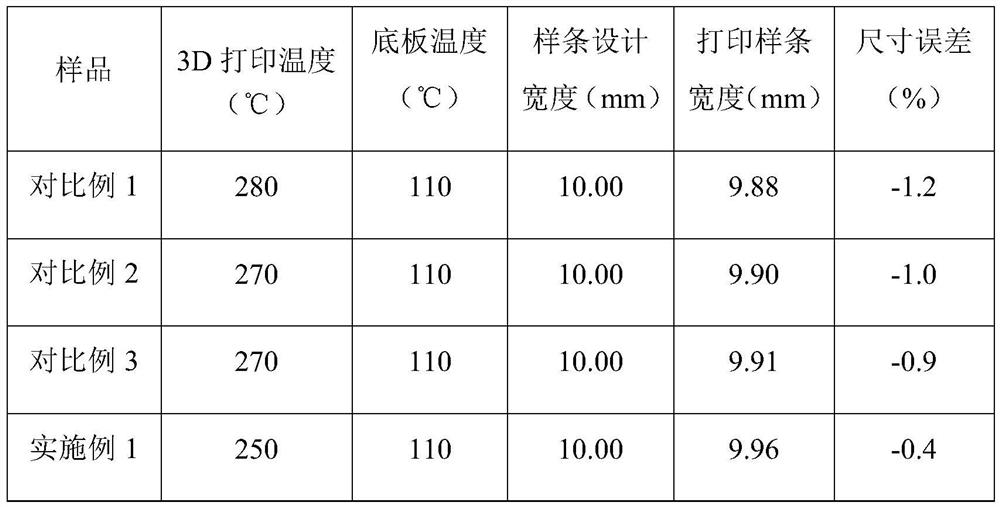

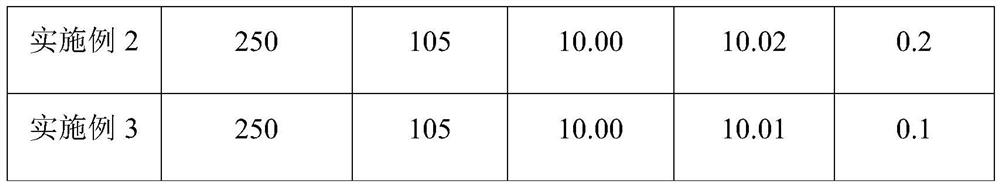

Examples

Embodiment 1

[0079] Take each raw material according to the following proportioning ratio: the mass fraction of PC is 80 parts, the mass fraction of PBAT is 20 parts, and the mass fraction of graphene dispersion liquid is 0.6 part (5% of graphene mass concentration, 10% of oxygen content in graphene ), the antioxidant mass number is 0.08 part. Mix PC, PBAT, graphene dispersion liquid and antioxidant evenly, feed the material through the hopper in the first section of the twin-screw extruder, melt and extrude, the strands are cooled in a water bath and then pelletized, the screw speed is 200r / min, The feeding speed is 1kg / h, and the temperature of each section of the extruder is 180-220°C. The collected particles were dried at 85°C for 4 hours, and packaged for later use.

Embodiment 2

[0081] The raw materials were weighed according to the following proportions: 80 parts by mass of PC, 20 parts by mass of PBAT, 1 part by mass of graphene dispersion, and 0.08 parts by mass of antioxidant. Mix PC, PBAT, graphene dispersion liquid and antioxidant evenly, feed the material through the hopper in the first section of the twin-screw extruder, melt and extrude, the strands are cooled in a water bath and then pelletized, the screw speed is 200r / min, The feeding speed is 1kg / h, and the temperature of each section of the extruder is 180-220°C. The collected particles were dried at 85°C for 4 hours, and packaged for later use.

Embodiment 3

[0083] The raw materials were weighed according to the following proportions: 80 parts by mass of PC, 20 parts by mass of PBAT, 2 parts by mass of graphene dispersion, and 0.08 parts by mass of antioxidant. Mix PC, PBAT and graphene dispersion evenly, feed through the hopper in the first section of the twin-screw extruder, melt and extrude, the strands are cooled in a water bath and then pelletized, the screw speed is 200r / min, and the feeding speed is 1kg / h, the temperature of each section of the extruder is 180-220°C. The collected particles were dried at 85°C for 4 hours, and packaged for later use.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com