Label not adhered to PVC (polyvinyl chloride)

A label and adhesion technology, applied in the field of labels, can solve the problems of easy adhesion of ink, easy color fading of ink, and appearance of PVC sun visors, etc., and achieve the effect of improving adhesion fastness, viscosity and anti-adhesion performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-4

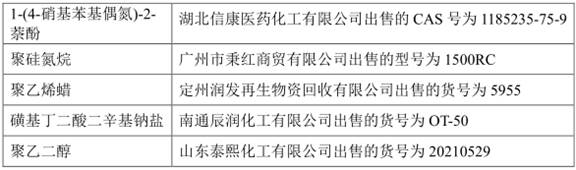

[0052]A label that does not adhere to PVC, comprising a bottom paper layer, a glue layer, a label paper layer and an ink layer arranged sequentially from bottom to top; the ink layer is made of the following raw materials by weight:

[0053] Color pigment; 1-(4-nitrophenylazo)-2-naphthol; nano titanium dioxide; polysilazane; defoamer; diluent.

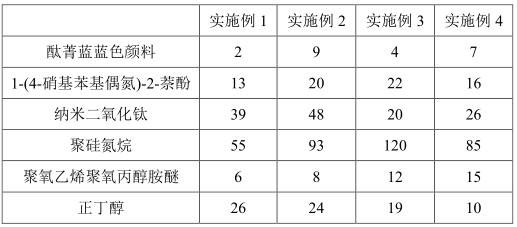

[0054] The preparation method of the ink layer is as follows: first mix 1-(4-nitrophenylazo)-2-naphthol, nano-titanium dioxide and polysilazane, stir at a speed of 100r / min for 20 minutes until uniform, Obtain a mixture; then add color pigments, defoamers and diluents to the mixture in sequence, stir at a speed of 60r / min for 30 minutes until uniform, and obtain an ink; finally print the prepared ink on the surface of the label paper layer , forming an ink layer.

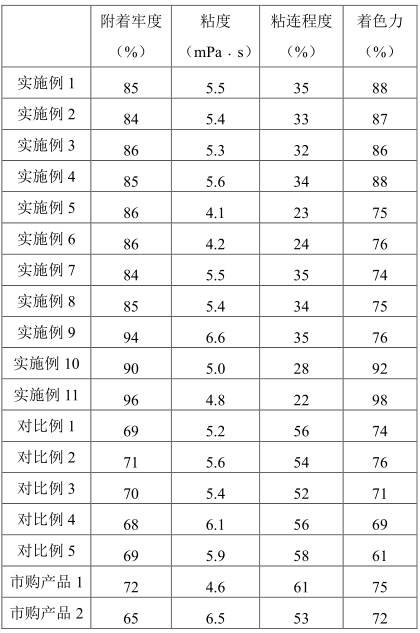

[0055] The dosage of each raw material of the ink layer is shown in Table 2, and the dosage unit of each raw material in Table 2 is kg.

[0056] Table 2

[0057]

Embodiment 5

[0059] The difference from Example 4 is that 28kg of polyethylene wax and 9kg of dioctyl sodium sulfosuccinate were mixed uniformly in advance, and then added to the mixture and mixed uniformly with other raw materials.

Embodiment 6

[0061] The difference from Example 4 is: 14kg of polyethylene wax and 20kg of dioctyl sodium sulfosuccinate were mixed uniformly in advance, and then added to the mixture and mixed uniformly with other raw materials.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com