Nickel-based high-temperature alloy strip refining method

A nickel-based superalloy and alloy material technology, applied in the direction of metal rolling, etc., can solve the problems of poor quality of finished nickel-based alloy, unreasonable production process, difficult quality assurance, etc., to improve performance, improve surface and internal quality, good effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be further described below.

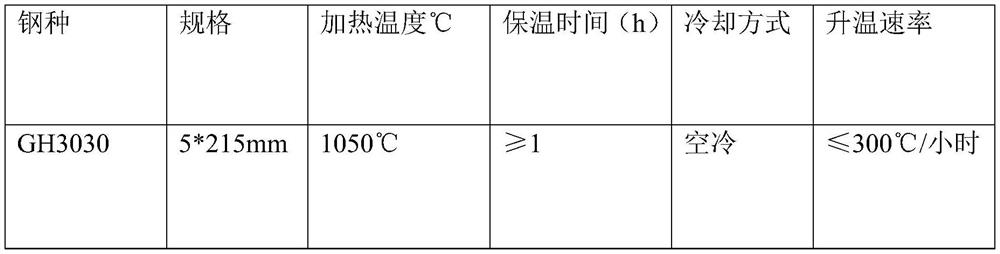

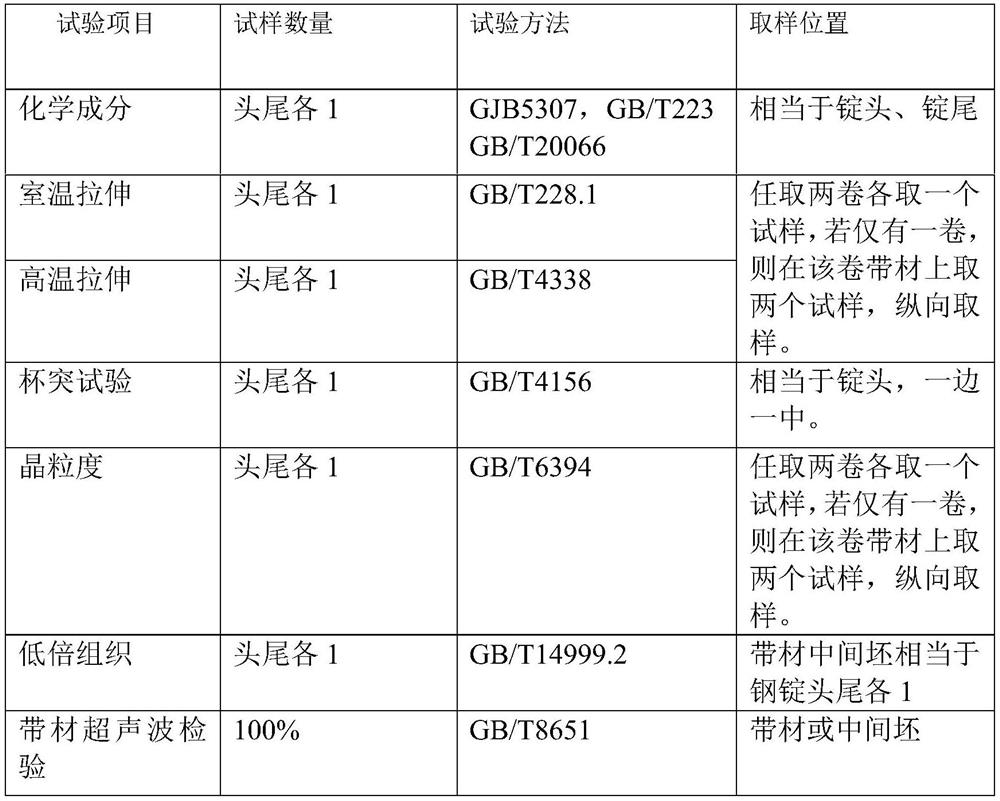

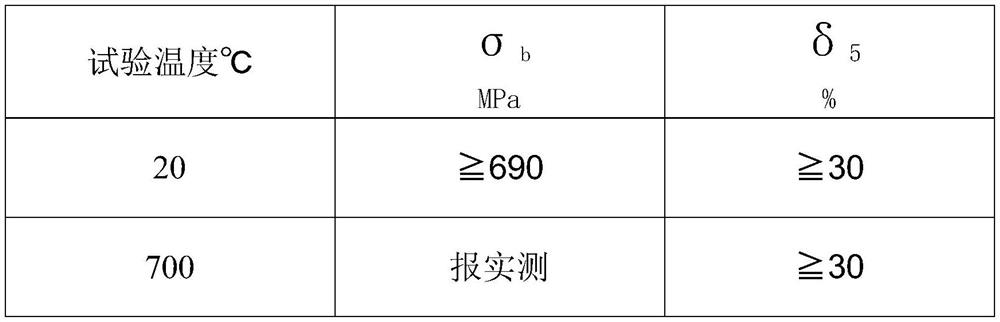

[0055] A kind of nickel base superalloy strip refining method of the present invention comprises the following steps,

[0056] Step (A), electroslag refining is carried out to the alloy material smelted through the vacuum induction furnace to produce steel ingots. The specific steps are as follows,

[0057] Step (A1), determine the baking temperature and baking time of the slag material, arc starting agent and electrode, and the materials used in the slag material, arc starting agent and electrode are fluorite, lime and alumina, and the fluorite Baking at 400°C for more than 4 hours, baking at 800°C for more than 8 hours for the lime, and baking at 300°C for more than 1 hour for the alumina;

[0058] Step (A2), determining the ratio of the electroslag system, and the ratio of fluorite: lime: alumina in the electroslag system is 7:1:2;

[0059] Step (A3), determining the power system, and the power system include...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com