Floating slab track vibration isolator integrating particle damping vibration absorption and band gap vibration resistance

A particle damping and floating plate technology, which is applied in the field of rail vibration and noise reduction, can solve the problems of increasing the bandgap width, difficulty in elastic lamination, and increasing thickness, so as to avoid the sharp increase of the resonance peak and meet the stiffness and low-frequency bandgap required effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

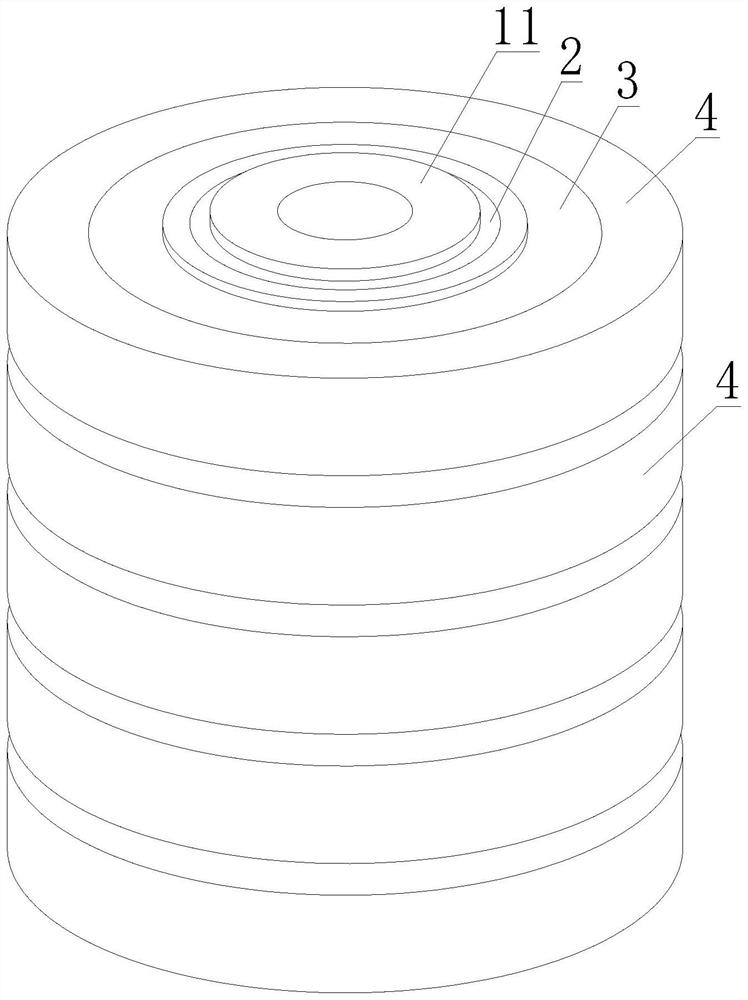

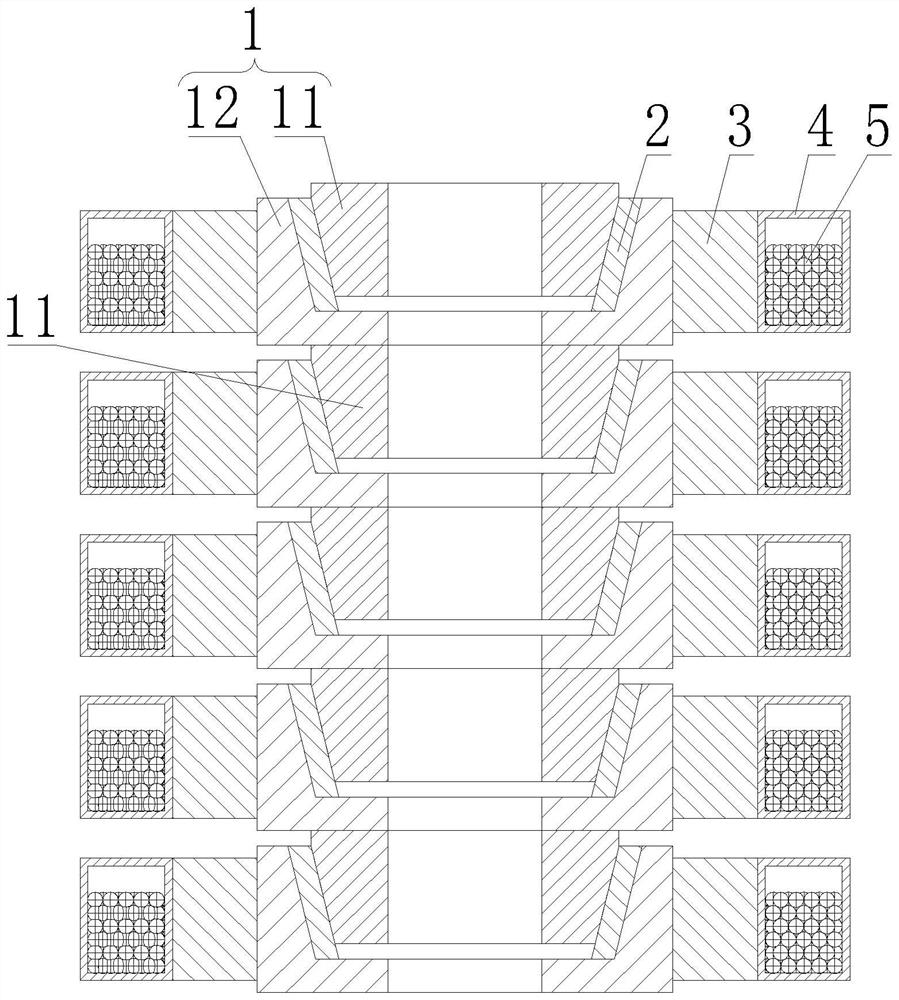

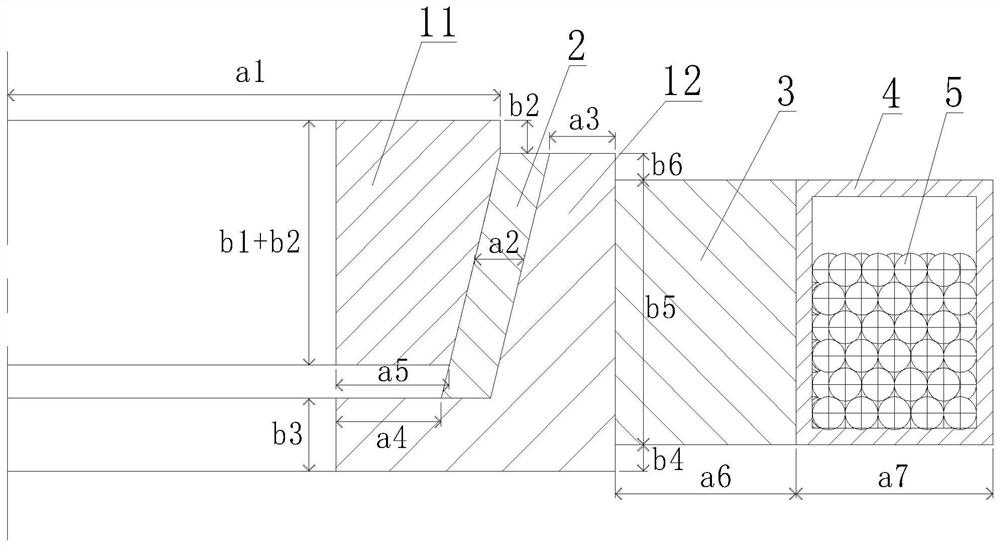

[0027] Such as Figure 1-2 As shown, the present invention proposes a floating plate rail vibration isolator that combines particle damping vibration absorption and band gap vibration isolation. , the outer ring rubber layer 3 and the steel vibrator shell 4 and a plurality of damping particles 5 filled in the steel vibrator shell 4, the connector 1 has a receiving groove, which has the function of reducing weight and facilitates the connection of the inner ring rubber layer 2. The inner ring rubber layer 2 is located in the accommodation groove, and the inner ring rubber layer 2 is connected to the connector 1, the outer ring rubber layer 3 is coaxially sleeved on the outer peripheral surface of the connector 1, and the steel vibrator shell 4 is sleeved on the outer ring rubber layer 3. On the outer peripheral surface, the steel vibrator housing 4 is cut along the plane passing through the central axis. The cross-sectional profile is rectangular, which facilitates the balanced...

Embodiment 2

[0030] The invention proposes a floating plate track vibration isolator that combines particle damping vibration absorption and band gap vibration isolation. Compared with Embodiment 1, in this embodiment, the connector 1 is made of aluminum alloy material, which is not easy to rust ,long lasting.

Embodiment 3

[0032] Such as figure 2 As shown, the present invention proposes a floating plate rail vibration isolator that combines particle damping vibration absorption and band gap vibration isolation. Compared with Embodiment 1, in this embodiment, the connector 1 includes an inner connector 11 and an outer Connectors 12 , the inner connectors 11 protrude from the outer connectors 12 , and in two adjacent groups of connectors 1 , the inner connectors 11 in one group of connectors 1 are connected to the outer connectors 12 in the other group of connectors 1 . Each group of vibration isolation components can be modularly connected through the connector 1, and an appropriate assembly quantity can be selected according to the size of the installation space.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com