Diesel engine respirator

A diesel engine and respirator technology, which is applied in the direction of machines/engines, mechanical equipment, engine components, etc., can solve the problems of not being able to separate the oil and reduce emissions, and achieve the effects of thorough separation of oil and gas, simplifying the manufacturing process, and delaying the flow speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

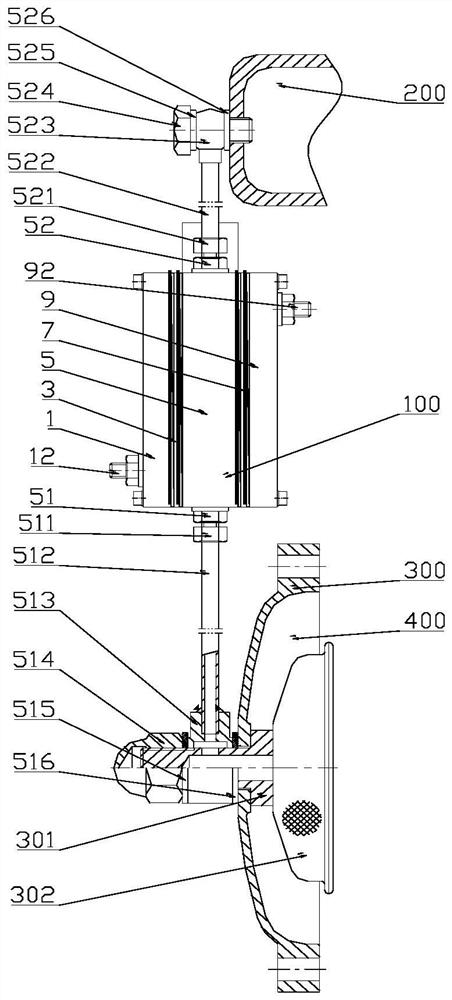

[0060] Such as figure 1 As shown, a diesel engine respirator includes a diesel engine intake pipe 200, an oil-gas condensing device 100, and a crankcase 400; the intake pipe 200 and the oil-gas condensing device 100 are communicated with the A connecting pipe 522; the oil-gas condensing device is connected with the B connecting pipe 512 100 communicates with crankcase 400 .

[0061] A connecting pipe 522 is used to communicate the intake pipe 200 with the oil-gas condensing device 100 . That is to say, the upper end of the A connecting pipe 522 and the A hinge body 523 are welded together, and the A hinge body 523 is fixedly communicated with the intake pipe 200 by using the hinge screw 524 and the A combined pad 526 and the B combined pad 525 . The lower end of the A connecting pipe 522 is provided with an A ferrule 521 and a bell mouth, and communicates with the air outlet 52 of the oil-gas condensing device 100. The air outlet 52 is a hexagonal external tooth pipe joint, a...

Embodiment 2

[0077] Other settings are the same as those in Embodiment 1 of the present invention.

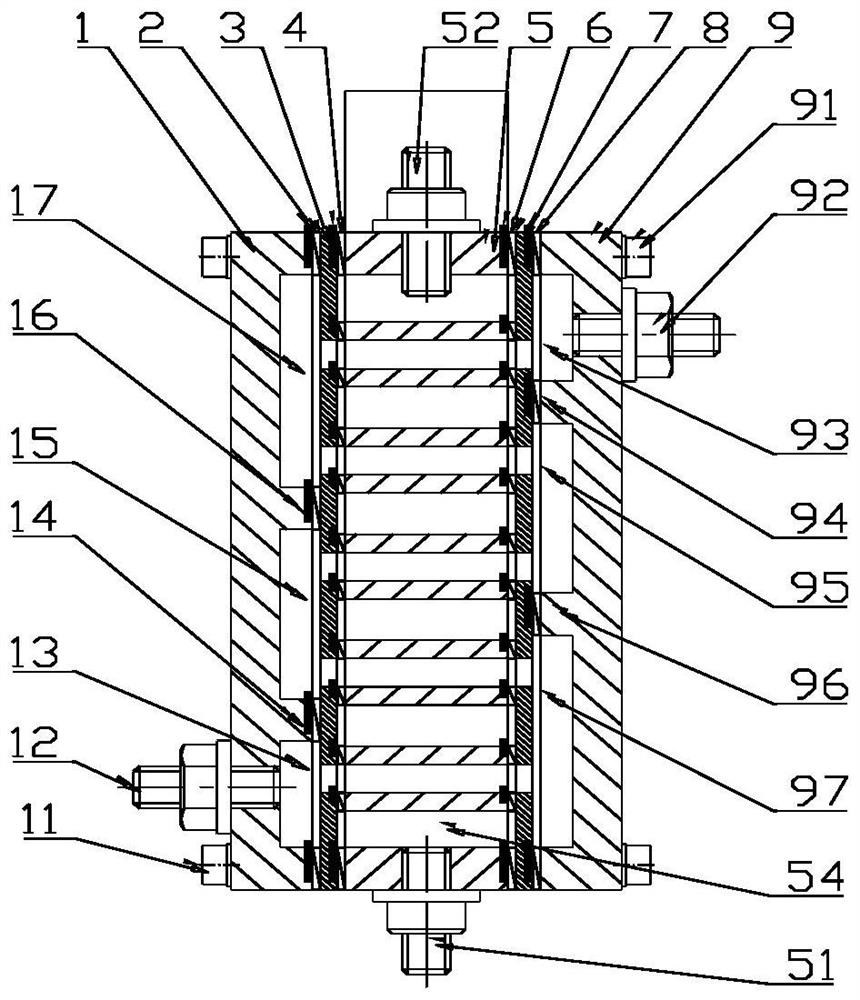

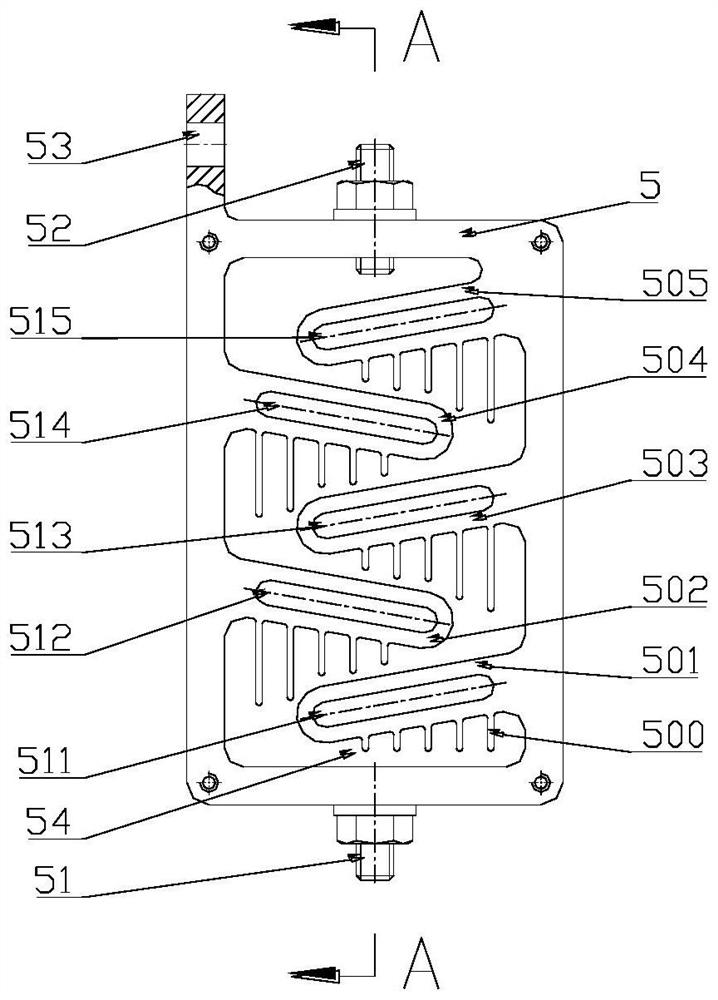

[0078] In this embodiment, in the body box hole, the total number of grid plates is an even number, and there are at least four grid plates;

[0079] The main body, in the box hole, is provided with two grid plates in the front and two grid plates in the back; the grid plates are respectively recorded as: the first grid plate, the second grid plate, the third grid plate, The fourth grid plate and its corresponding waterways are recorded as: the first waterway, the second waterway, the third waterway, and the fourth waterway;

[0080] The number, shape, and position of the waterway holes on the left and right separating plates correspond to the waterways on the body; the names of the waterway holes are, from bottom to top, respectively recorded as: the first waterway hole, the second waterway hole, The third channel hole and the fourth channel hole.

[0081] The right end face of the left ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com