Engine protective coating liquid and preparation method thereof

A technology of protective coating and engine, applied in the direction of coating, etc., can solve problems such as poor engine repair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

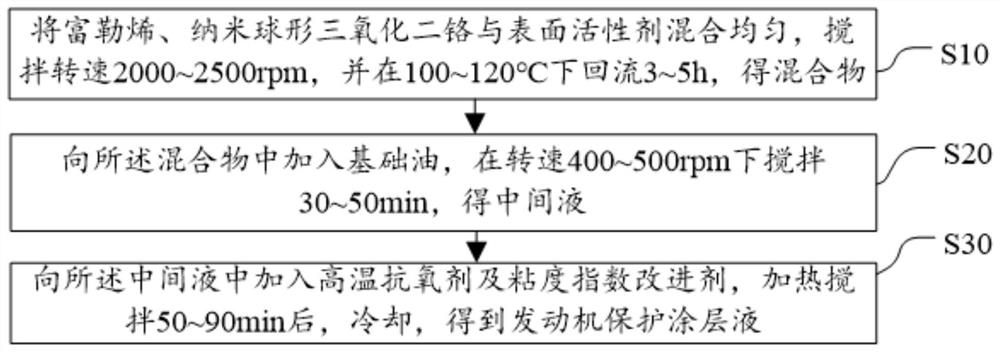

[0047] The present invention further proposes a method for preparing the above-mentioned engine protective coating liquid, figure 1 It is a schematic flow chart of an embodiment of the preparation method of the engine protective coating solution proposed by the present invention. see figure 1 , the preparation method of the engine protective coating liquid comprises the following steps:

[0048] S10. Uniformly mixing fullerene, nano-spherical chromium trioxide and surfactant at a stirring speed of 2000-2500 rpm, and refluxing at 100-120°C for 3-5 hours to obtain a mixture;

[0049] S20, adding base oil to the mixture, and stirring at a rotation speed of 400-500 rpm for 30-50 minutes to obtain an intermediate liquid;

[0050] S30. Add a high-temperature antioxidant and a viscosity index improver to the intermediate liquid, heat and stir for 50-90 minutes, and then cool to obtain an engine protective coating liquid.

[0051] In the above steps, under high-speed stirring, full...

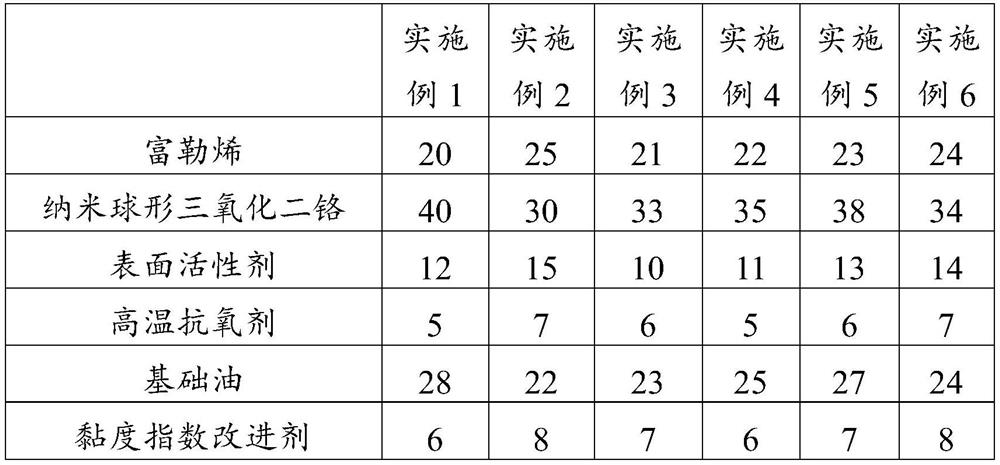

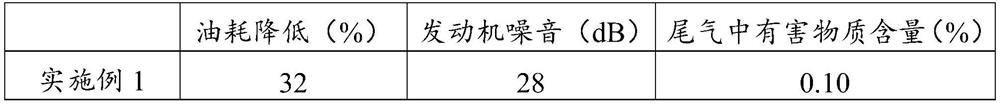

Embodiment 1

[0065] (1) Under heating conditions, spherical chromium trioxide and surface modifier (hexadecyltrimethylammonium bromide, the mass ratio of surface modifier to nano-spherical chromium trioxide is 1:20) mixed ball mill Afterwards, ultrasonic treatment to obtain nano-spherical chromium trioxide;

[0066] (2) Mix fullerene with a particle size of 3 μm and nano-spherical chromium trioxide with a particle size of 40 nm and a sphericity of 0.8 with surfactant Tween-80, stir at a speed of 2000 rpm, and reflux at 100 ° C 3h, the mixture was obtained;

[0067] (3) Add base oil (alpha olefin) to the mixture, and stir for 30 minutes at a rotating speed of 400 rpm to obtain an intermediate liquid;

[0068] (4) Add a high-temperature antioxidant (2,6 di-tert-butyl-p-cresol) and a viscosity index improver (polymethacrylate) to the intermediate liquid, heat and stir for 50 minutes, then cool to obtain an engine protection coating layer of liquid.

Embodiment 2

[0070] (1) Under heating conditions, spherical chromium trioxide and surface modifier (sodium dodecylbenzenesulfonate, the mass ratio of surface modifier to nano-spherical chromium trioxide is 1:50) are mixed and ball-milled, Ultrasonic treatment to obtain nano-spherical chromium trioxide;

[0071] (2) Mix fullerene with a particle size of 1 μm and nano-spherical chromium trioxide with a particle size of 50 nm and a sphericity of 1 with surfactant Tween-80, stir at a speed of 2500 rpm, and reflux at 120 ° C 5h, the mixture was obtained;

[0072] (3) Add base oil (vegetable oil) to the mixture, and stir for 50 min at a rotating speed of 500 rpm to obtain an intermediate liquid;

[0073] (4) Add a high-temperature antioxidant (mercaptobenzothiazole) and a viscosity index improver (polyisobutylene) into the intermediate liquid, heat and stir for 90 minutes, then cool to obtain an engine protective coating liquid.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com