Raw material preparation device for humic acid soil remediation agent

A technology of soil remediation agent and preparation device, which is applied in the field of raw material preparation device of humic acid soil remediation agent, which can solve the problems of waste of weathered coal, low conversion rate of coal humic acid, and affecting the repair function of soil remediation agent, so as to improve the transformation The effect of speed and acceleration of cleaning time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

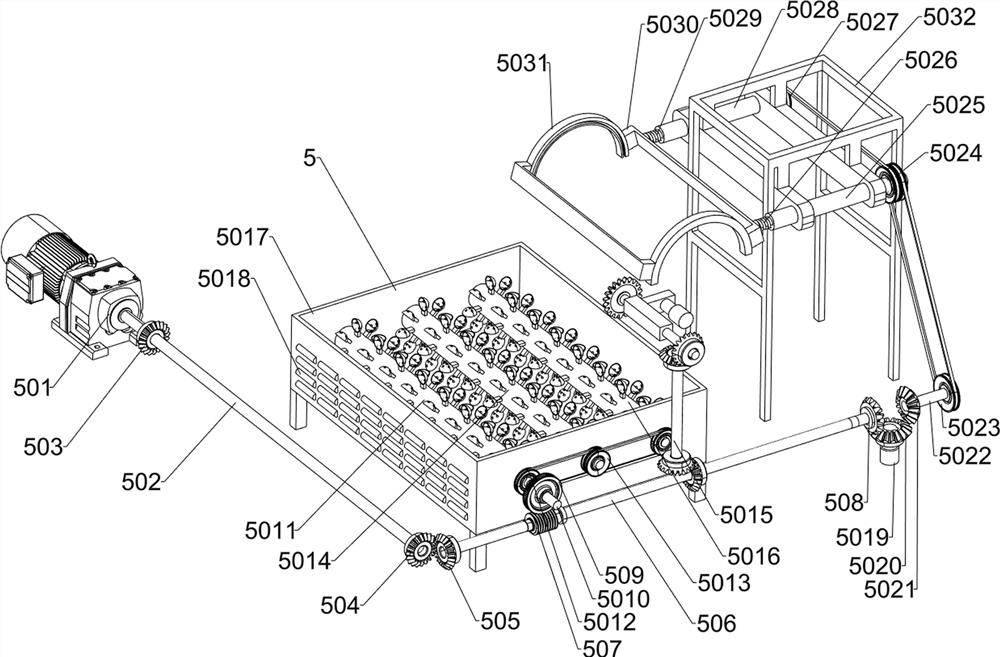

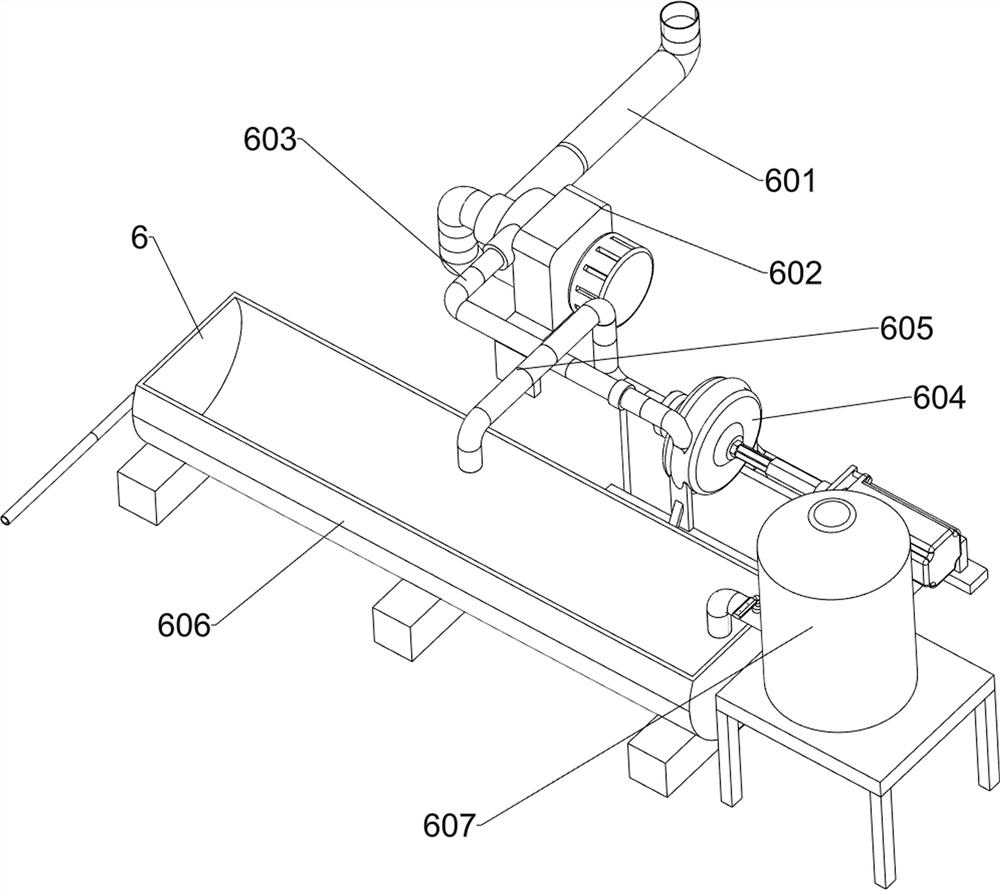

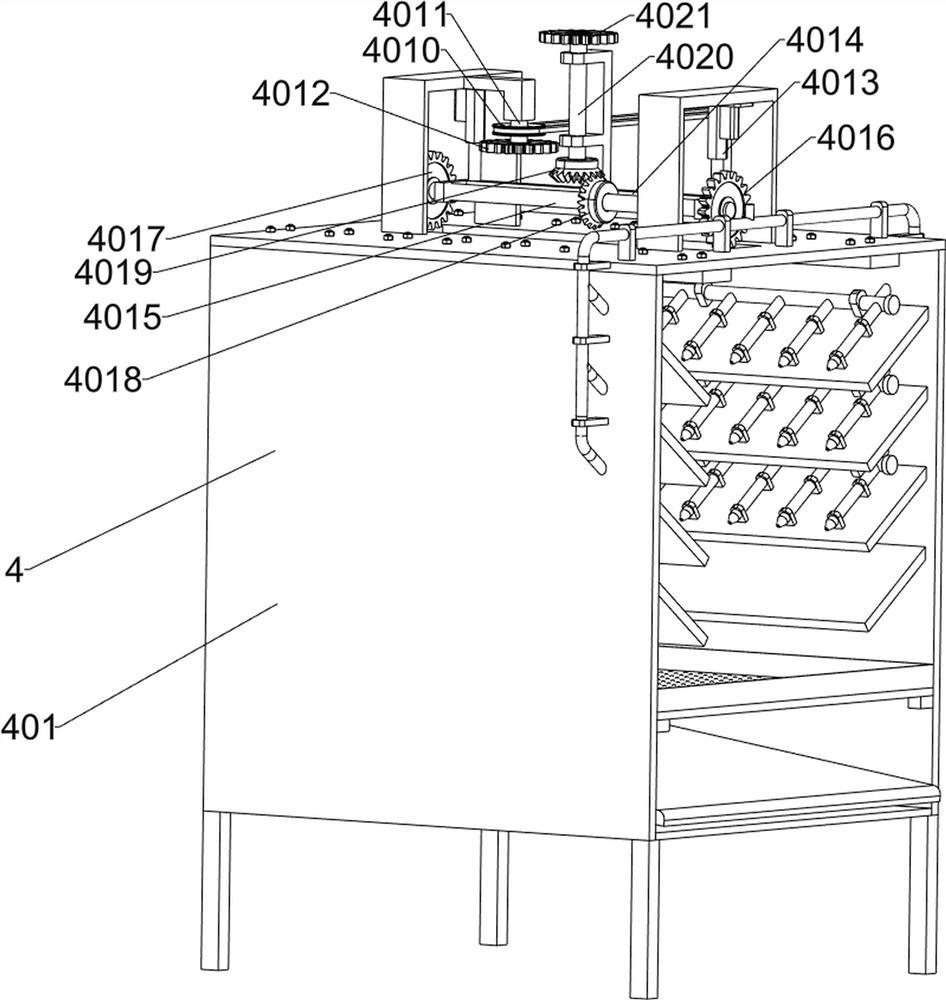

[0033] Raw material preparation device for humic acid soil repair agent, such as Figure 1-12 As shown, including the bottom plate 1, the control screen 2, the upper delivery system 3, the crush cleaning filter system 4, the stirring system 5, and the centrifugal system 6; the bottom plate 1 is connected to the upper delivery system 3; the bottom plate 1 and the crushed material The cleaning filter system 4 is connected; the bottom plate 1 is connected to the stirring system 5; the bottom plate 1 is connected to the centrifugation system 6; the control screen 2 is connected to the stirring system 5; the upper delivery system 3 is connected to the straw cleaning filter system 4 The straw cleaning filtration system 4 is connected to the stirring system 5; the agitation system 5 is connected to the centrifugal system 6.

[0034] The device is installed in a smooth working place, an external power source, and manually operating the control screen 2 start, and view the operational trans...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com