System and process for large-grain crystallization of ammonium sulfate

A crystallization system and ammonium sulfate technology, applied in the field of ammonia desulfurization, can solve the problems of equipment wear, difficulty in discharging, and short fertilizer effect time, and achieve the effects of improving utilization rate, convenient transportation and precise control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

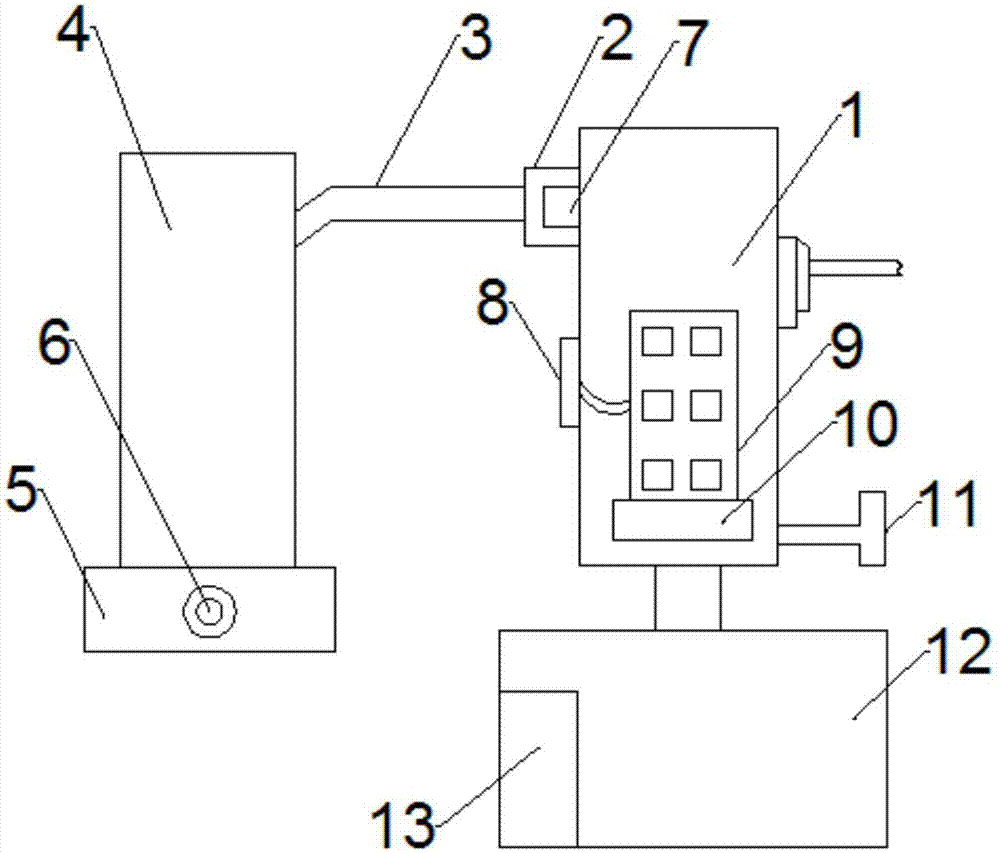

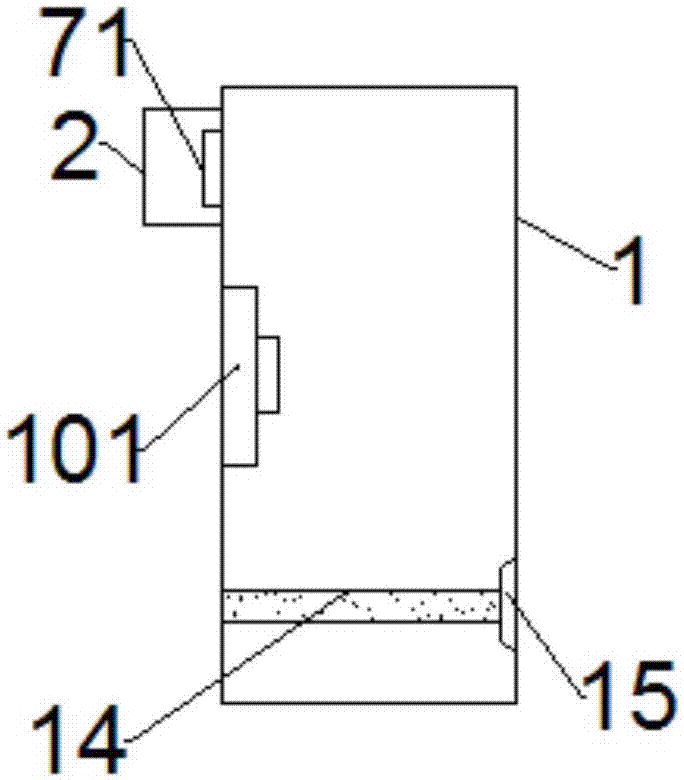

[0035] see Figure 1 to Figure 5 , the present invention provides a technical solution:

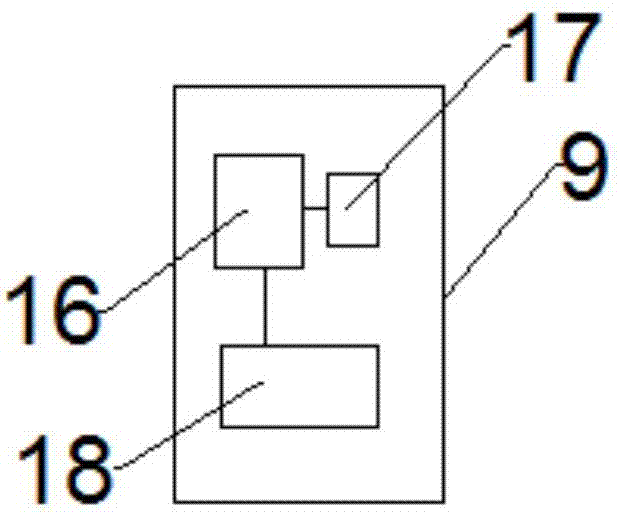

[0036] A system for the crystallization of large particles of ammonium sulfate, comprising a crystallization tank, a recovery tank and a storage tank, and also including a return pipeline, a main control board, a first temperature sensor and a second temperature sensor, one end of the return pipeline is connected to the recovery tank. The upper end of the tank is connected, and the other end of the return pipe is connected to the upper end of the crystallization tank through the pump body. The first temperature sensor is installed at the connection end of the pump body and the crystallization tank, and the first display screen is installed on the pump body. signal connection between the first display screen, the first temperature sensor and the main control board;

[0037] The temperature in the crystallization tank can be heated by the heater, and the first temperature sensor and the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com