H-shaped transmission structure for vehicle and vehicle with H-shaped transmission structure

A transmission structure and vehicle-used technology, which is applied in the field of vehicle transmission, can solve the problems of difficult vehicle space layout, complex transmission structure, and large occupied space, and achieve the effect of saving layout space, simple structure, and small occupied space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

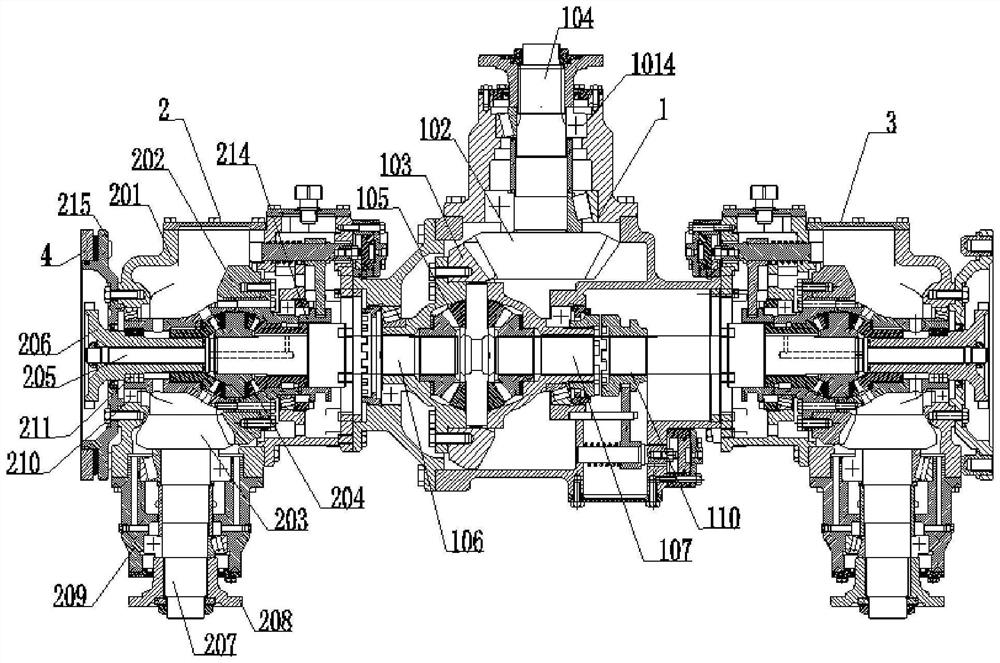

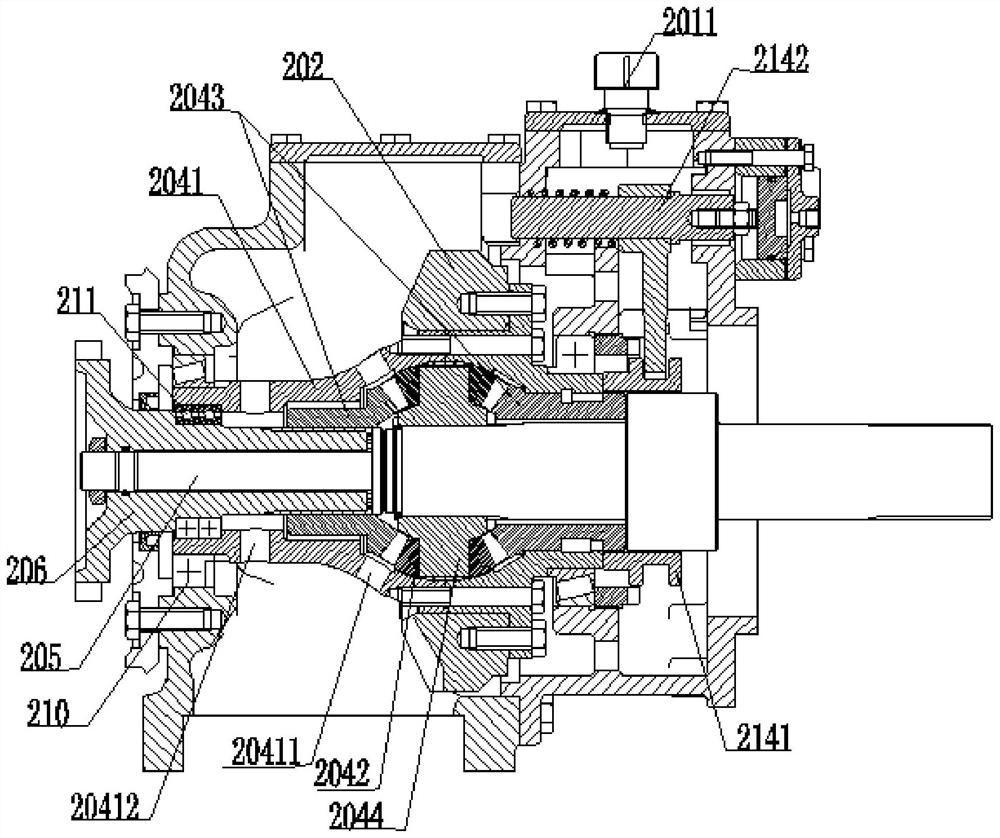

[0050] This embodiment provides an H-type transmission structure for vehicles, such as figure 1 As shown, it includes the final reducer assembly 1 and the left reducer assembly 2 and the right reducer assembly 3 respectively arranged on the left and right sides of the final reducer assembly;

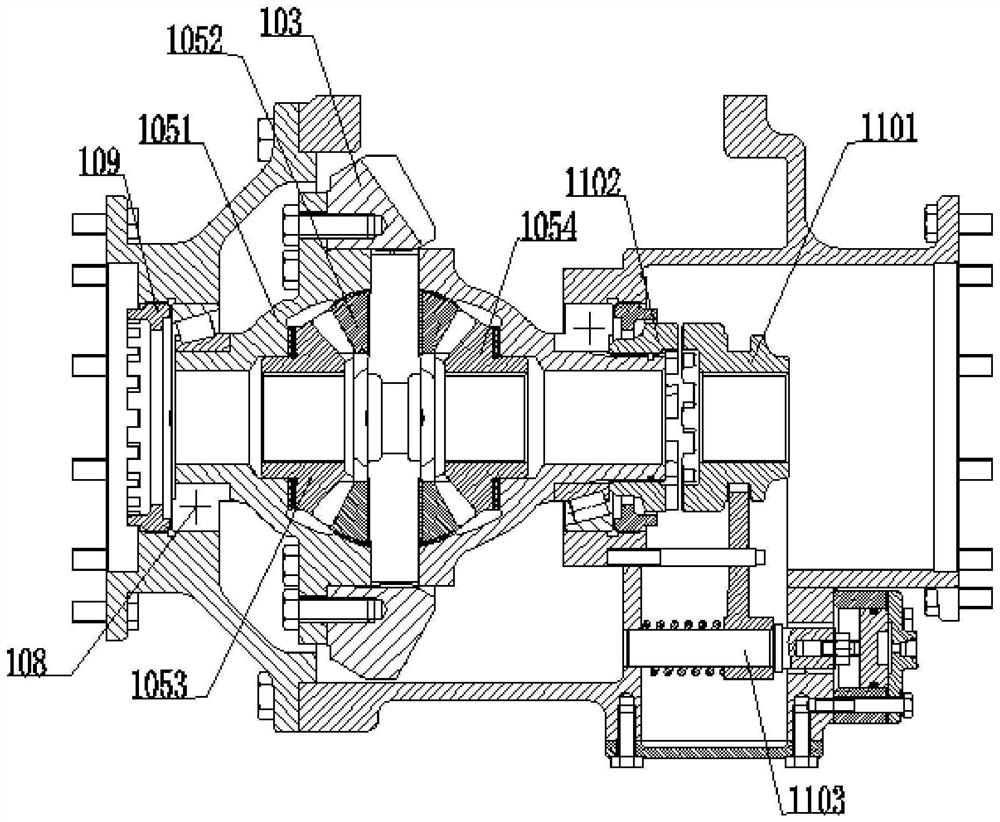

[0051] The final reducer assembly 1 includes a final reducer housing 101 and a final drive bevel gear 102, a final drive driven bevel gear 103, an input shaft 104, an inter-wheel differential 105, and a left half Shaft 106 and right half shaft 107, the driving bevel gear 102 of the main reducer is fixedly connected with the input shaft 104, the driving bevel gear 102 of the main reducer is meshed with the driven bevel gear 103 of the main reducer; the inter-wheel differential 105 includes an inter-wheel differential case 1051, an inter-wheel differential planetary gear 1052, an inter-wheel differential left side shaft gear 1053 and an inter-wheel differential right side shaft gear 1054, ...

Embodiment 2

[0082] A vehicle, which is driven by the transmission structure described in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com