Energy-saving drying machine for new material manufacturing

A dryer and new material technology, applied in the direction of static material dryers, local mixing dryers, dryers, etc., can solve the problems of heat loss in the drying box, inconvenient handling, unfavorable drying, etc., to achieve reduction The effect of heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

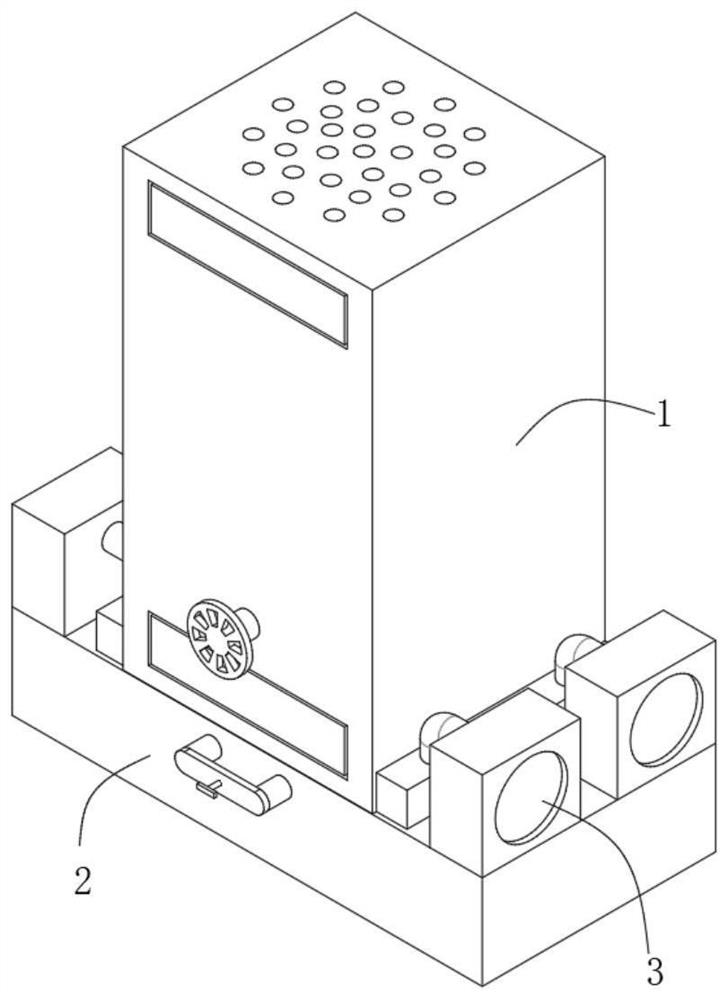

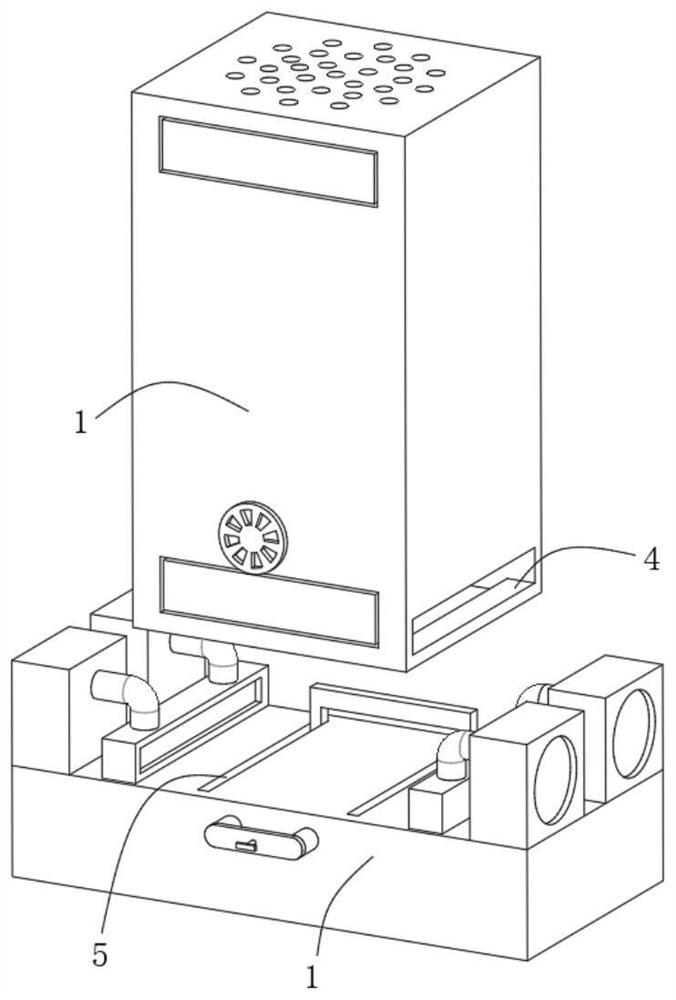

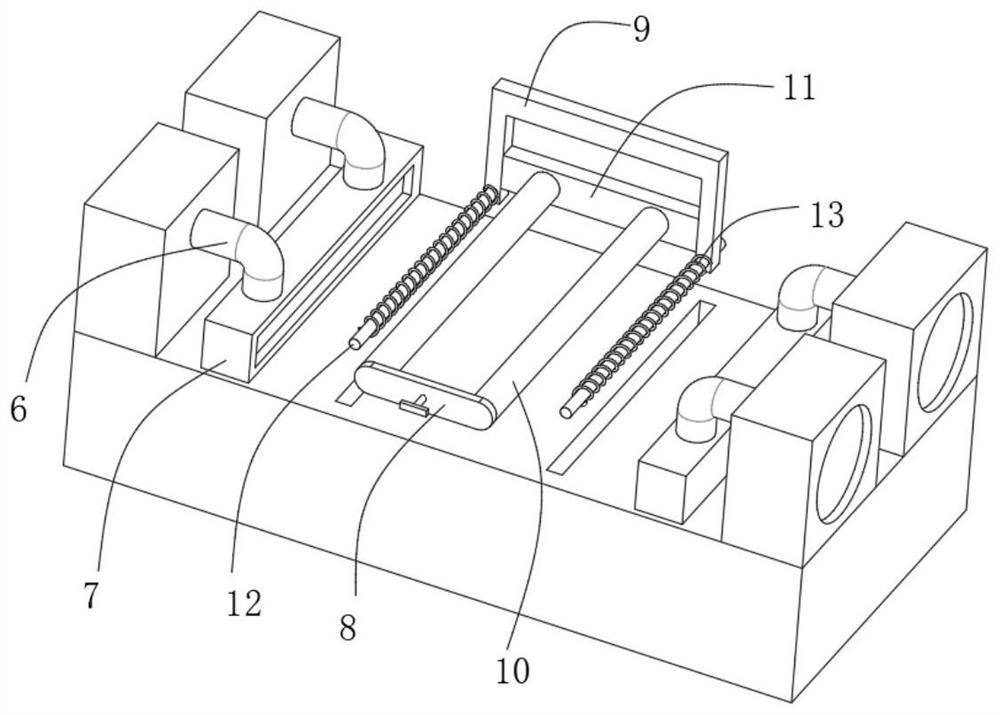

[0030] Such as Figure 1-7 An energy-saving drying machine for making new materials is shown, including a drying box 1, the top of the drying box 1 is provided with an exhaust hole, the bottom of the drying box 1 is fixedly connected with a base 2, and the upper surface of the base 2 is located in the drying box. Both sides of 1 are fixedly connected with fan 3, and the fan 3 is connected with the bottom of the drying box 1. The top of the outer surface of the drying box 1 is provided with a feed port 14, and the bottom of the outer surface of the drying box 1 is provided with a discharge port. Port 15, feed port 14 and discharge port 15 are hinged with rotating baffles 16 inside, drying baffles 20 are provided inside the drying box 1, and both sides of the inner wall of the drying box 1 are fixedly connected with limit stops. 19. Both sides of the drying baffle 20 are fixedly connected with the limit block 21, the limit block 21 is slidably connected to the middle of the limi...

Embodiment 2

[0033] Such as Figure 1-7 An energy-saving drying machine for making new materials is shown, including a drying box 1, the top of the drying box 1 is provided with an exhaust hole, the bottom of the drying box 1 is fixedly connected with a base 2, and the upper surface of the base 2 is located in the drying box. Both sides of 1 are fixedly connected with fan 3, and the fan 3 is connected with the bottom of the drying box 1. The top of the outer surface of the drying box 1 is provided with a feed port 14, and the bottom of the outer surface of the drying box 1 is provided with a discharge port. Port 15, feed port 14 and discharge port 15 are hinged with rotating baffles 16 inside, drying baffles 20 are provided inside the drying box 1, and both sides of the inner wall of the drying box 1 are fixedly connected with limit stops. 19. Both sides of the drying baffle 20 are fixedly connected with the limit block 21, the limit block 21 is slidably connected to the middle of the limi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com