Ultrathin flexible vapor chamber and preparation method thereof

A vapor chamber and flexible technology, applied in the field of ultra-thin flexible vapor chamber and its preparation, can solve the problems of vapor chamber performance deterioration, vacuum degree increase, water and oxygen penetration, etc., and achieve improvement of degradation or even failure. Implementation method Simple, guarantee the effect of flexible functional features

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

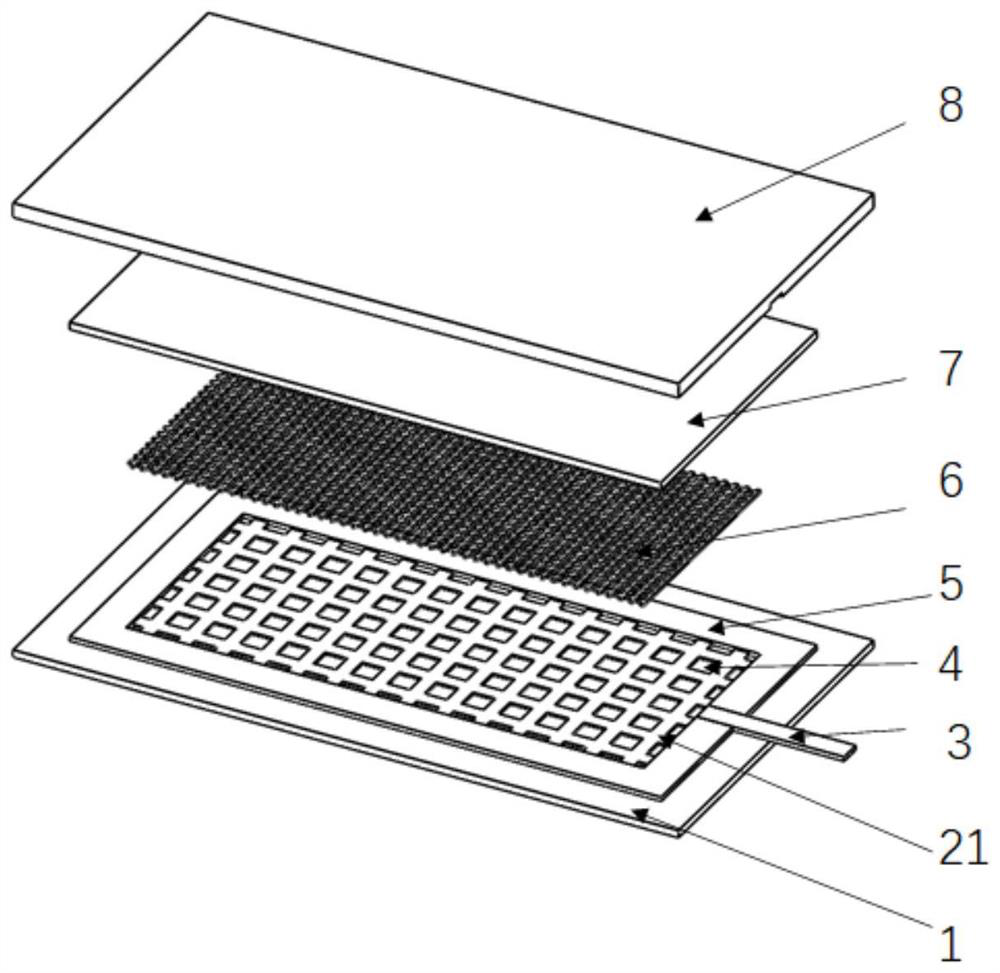

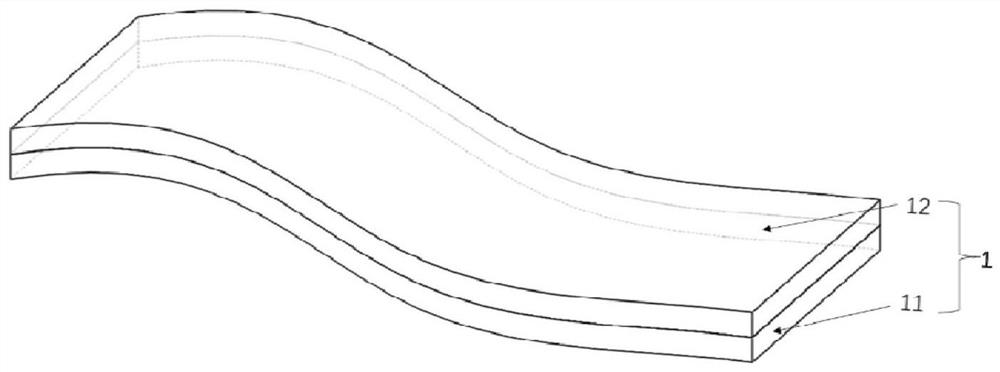

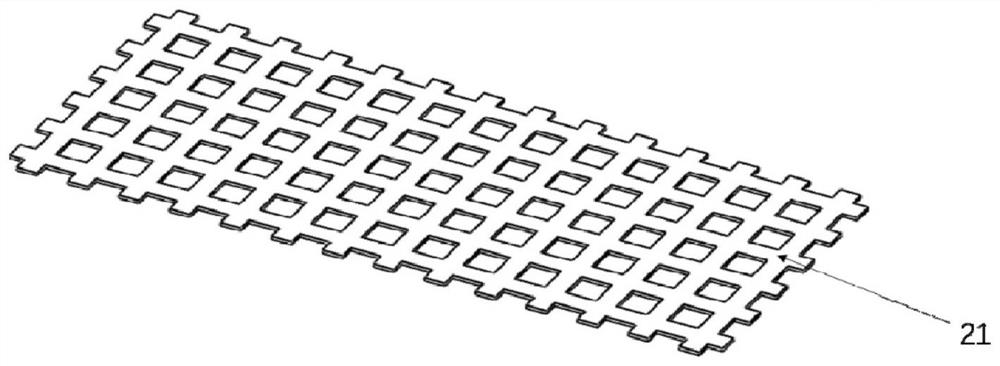

[0035] Such as figure 1 As shown, an ultra-thin flexible vapor chamber includes: a lower shell 1, an airway structure layer, a liquid injection pipe 3, a working fluid 4, a first connecting layer 5 (welding layer), a liquid-absorbing core 6, and an upper shell Body 7 and flexible second hermetic encapsulation layer 8. The airway structure layer is placed above the lower shell 1, the liquid-absorbing core 6 is closely attached to the airway structure layer, the first connecting layer 5 reserves the position of the liquid injection pipe 3, and the upper and lower shells are completed once through the first connecting layer 5 Sealed connection, and the second sealing packaging layer 8 is deposited through the reserved size difference between the upper and lower casings to complete the secondary protection packaging. Finally, the working medium 4 is poured with deionized water, and the interior is vacuumed to realize the ultra-thin flexible vapor chamber.

[0036] Such as figu...

Embodiment 2

[0048] The preparation steps are substantially the same as in Example 1, except that:

[0049] In step S1, aluminum-plastic film is selected as the housing material, and the thickness is 0.1 mm.

[0050] In step S2, the stainless steel wire mesh is selected as a template to transfer to form the PDMS airway structure layer 22, the thickness of the stainless steel wire mesh is 0.2mm, and the number of meshes is 50 mesh. The transfer process is as follows:

[0051] (1) Prepare the main glue B glue and curing agent A glue required for PDMS, and mix them evenly according to the weight ratio of 10:1.

[0052] (2) The mixed PDMS colloid was vacuumed and rotated for 5 minutes in a vacuum degassing machine.

[0053] (3) Prepare a stainless steel wire mesh, cut it to an appropriate size, and clean it ultrasonically for 5 minutes with acetone, isopropanol, and absolute ethanol in sequence.

[0054] (4) Scrape-coat the PDMS colloid on the surface of the stainless steel wire mesh, and p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Mesh | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com