Sensitivity-adjustable flexible tactile sensor capable of accurately positioning stress

A tactile sensor, precise positioning technology, applied in the direction of instruments, measuring force, measuring devices, etc., to achieve the effect of precise force positioning, easy sensitivity, and prevention of crosstalk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

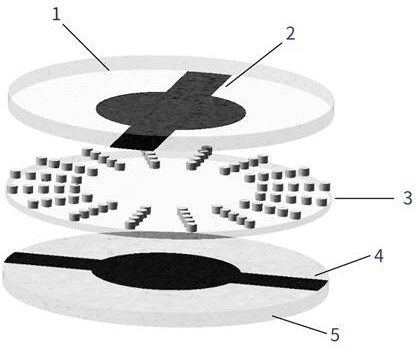

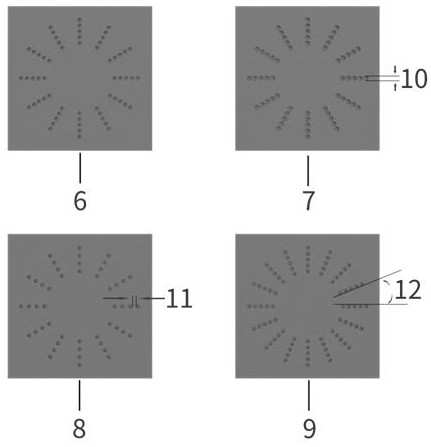

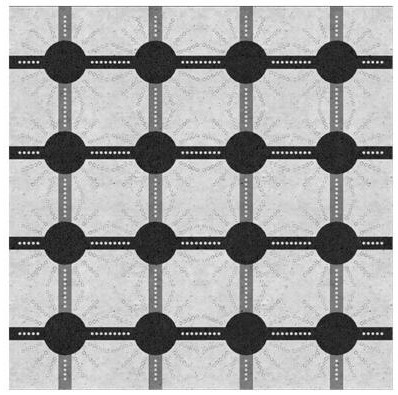

[0044] A method for manufacturing a sensitivity-adjustable capacitive flexible tactile sensor that can realize precise force positioning. The structure of the bosses on the dielectric layer is: the diameter of the bosses is 70 μm, the spacing between the bosses is 35 μm, and the angle between the bosses is 30°, including Follow the steps below:

[0045] (1) First prepare the graphene / PDMS film;

[0046] Put the germanium (110) substrate into the furnace, pass in hydrogen and argon or nitrogen to protect and heat to about 1000°C, stabilize the temperature, and keep it for about 20 minutes; then stop feeding the protective gas, and switch to carbon source (such as methane) Gas, about 30 minutes, the reaction is complete; cut off the power supply, turn off the methane gas, and then pass through the protective gas to exhaust the methane gas, until the tube is cooled to room temperature under the protective gas environment, take out the germanium (110) substrate, and obtain the ger...

Embodiment 2

[0062] A method for manufacturing a sensitivity-adjustable capacitive flexible tactile sensor that can realize precise force positioning. The structure of the bosses on the dielectric layer is: the diameter of the bosses is 85 μm, the spacing between the bosses is 20 μm, and the angle between the bosses is 30°, including Follow the steps below:

[0063] (1) First prepare the graphene / PDMS film;

[0064] Put the germanium (110) substrate into the furnace, pass in hydrogen and argon or nitrogen to protect and heat to about 1000°C, stabilize the temperature, and keep it for about 20 minutes; then stop feeding the protective gas, and switch to carbon source (such as methane) Gas, about 30 minutes, the reaction is complete; cut off the power supply, turn off the methane gas, and then pass through the protective gas to exhaust the methane gas, until the tube is cooled to room temperature under the protective gas environment, take out the germanium (110) substrate, and obtain the ger...

Embodiment 3

[0081] A method for manufacturing a sensitivity-adjustable capacitive flexible tactile sensor that can realize precise force positioning. The structure of the bosses on the dielectric layer is: the diameter of the bosses is 70 μm, the spacing between the bosses is 70 μm, and the angle between the bosses is 30°, including Follow the steps below:

[0082] (1) First prepare the graphene / PDMS film;

[0083] Put the germanium (110) substrate into the furnace, pass in hydrogen and argon or nitrogen to protect and heat to about 1000°C, stabilize the temperature, and keep it for about 20 minutes; then stop feeding the protective gas, and switch to carbon source (such as methane) Gas, about 30 minutes, the reaction is complete; cut off the power supply, turn off the methane gas, and then pass through the protective gas to exhaust the methane gas, until the tube is cooled to room temperature under the protective gas environment, take out the germanium (110) substrate, and obtain the ger...

PUM

| Property | Measurement | Unit |

|---|---|---|

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com