High-performance flexible contact force sensor and preparation method thereof

A sensor and high-performance technology, applied in the field of high-performance flexible touch force sensor and its preparation, can solve problems such as poor stability, slow response speed, and limited pressure measurement range, and achieve high stability, high linearity, and strong durability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The high-performance flexible touch force sensor proposed by the present invention and its preparation method are described as follows in conjunction with the accompanying drawings and examples.

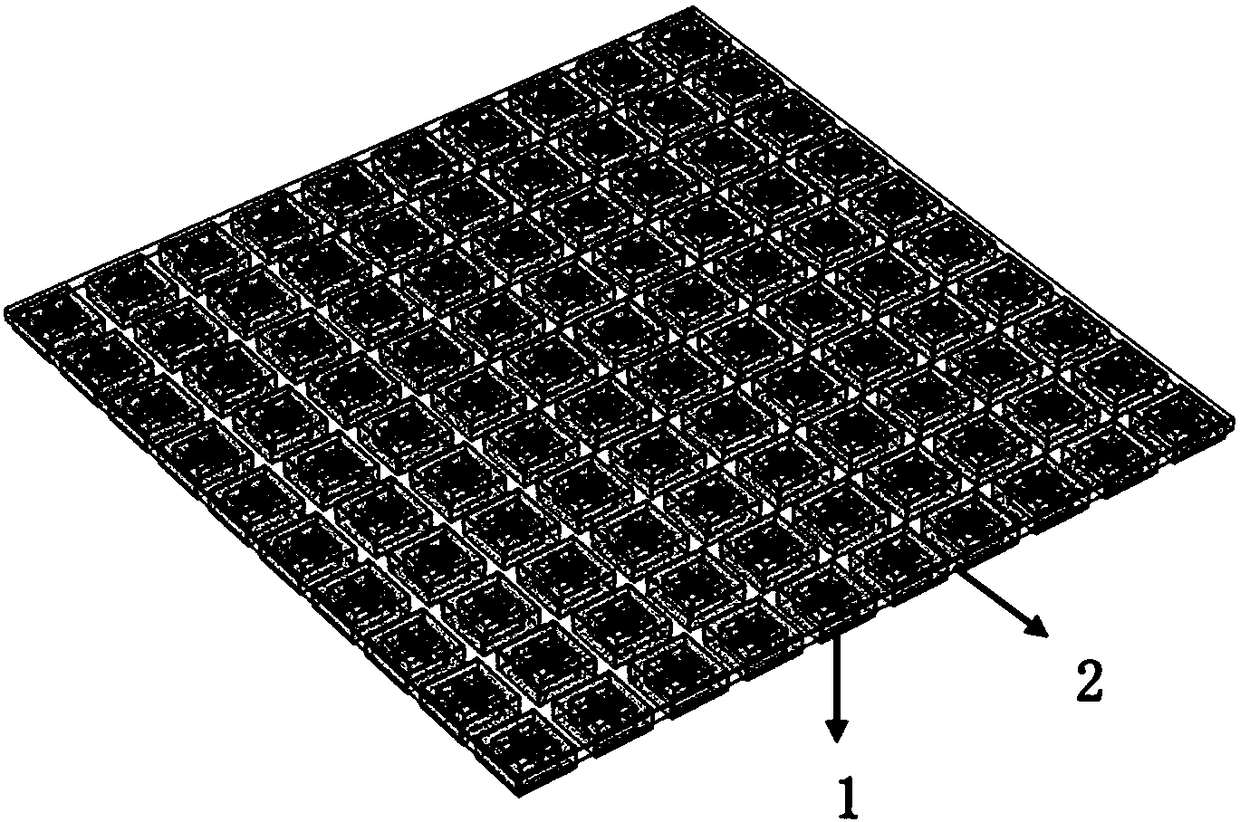

[0044] The n×m flexible touch force sensing array that can be realized by the high-performance flexible touch force sensor technology proposed in this embodiment is as follows: figure 1 as shown, figure 1 where n=m=10. Among them, the force sensor is a MEMS silicon-based piezoresistive force sensor 1, two adjacent sensors are connected by a certain thickness of parylene (Parylene) 2, and the surface of the sensor is also conformally deposited with a certain thickness of parylene. Toluene (Parylene)2.

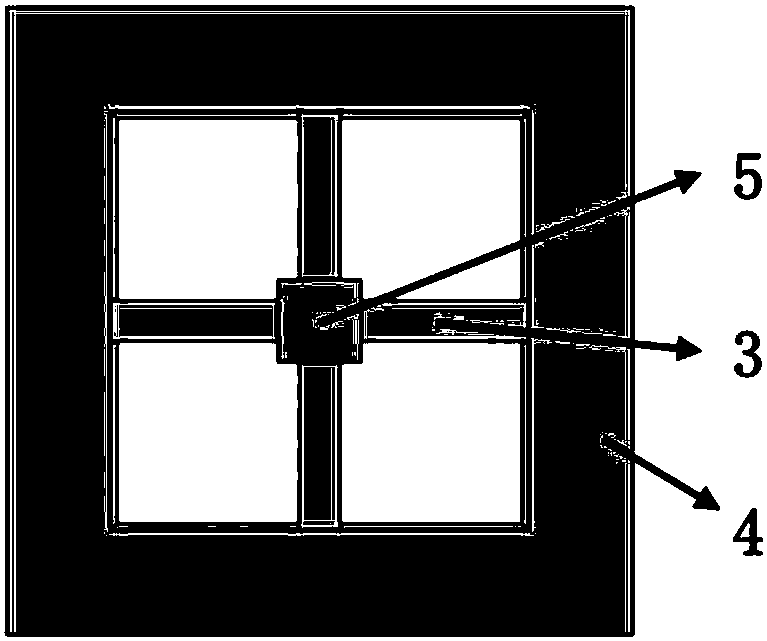

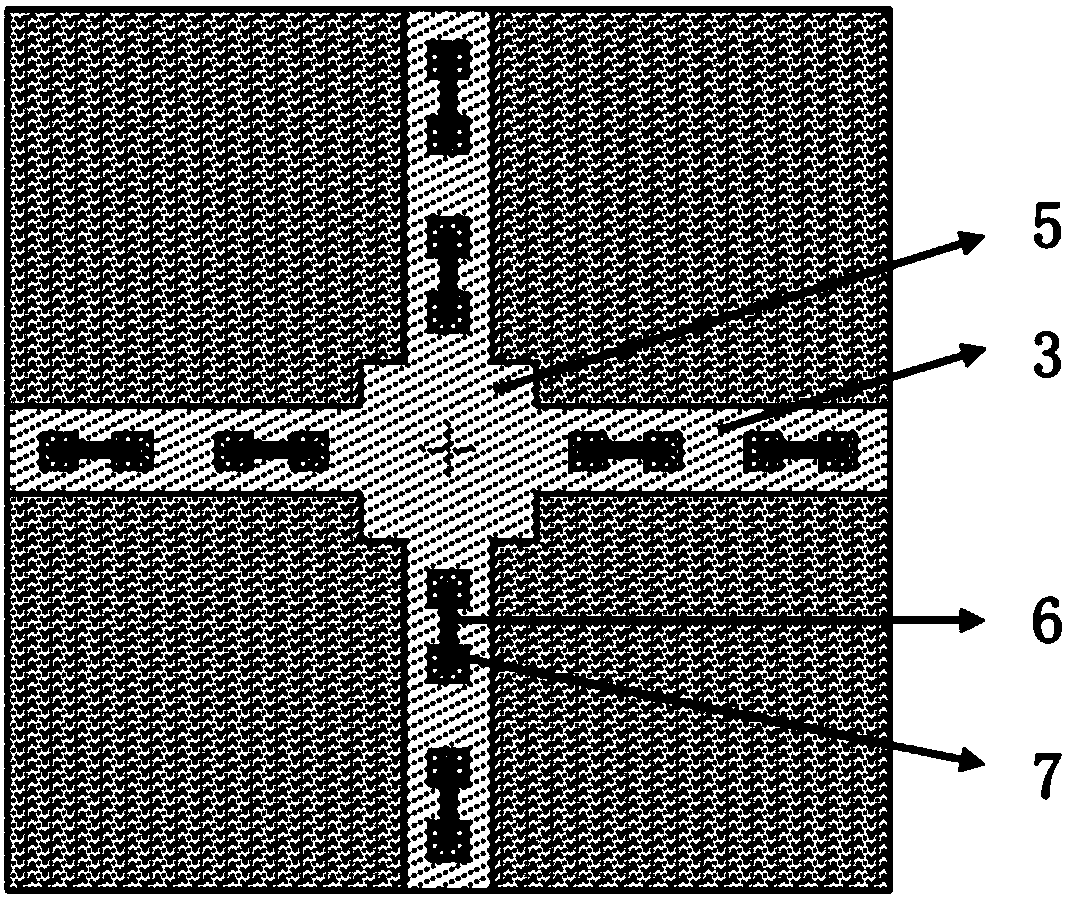

[0045] The structure of the MEMS silicon-based piezoresistive touch sensor 1 is shown in Figure 2(a), in which the freely suspended elastic cantilever beam 3 is connected to the peripheral support frame 4 and the internal suspended silicon block 5, and when pressure is applied...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com