Device and method for preparing electrolyte standard sample on site

A technology of electrolyte and standard sample, which is applied in the field of electrolyte standard sample preparation, can solve problems such as dust pollution, and achieve the effects of saving labor, improving efficiency, and eliminating dust

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

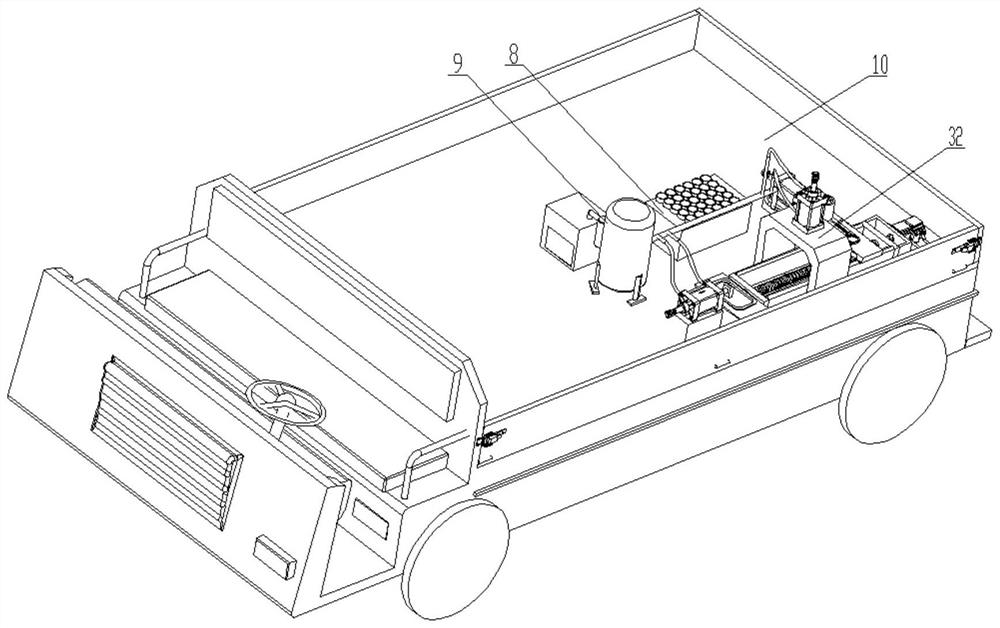

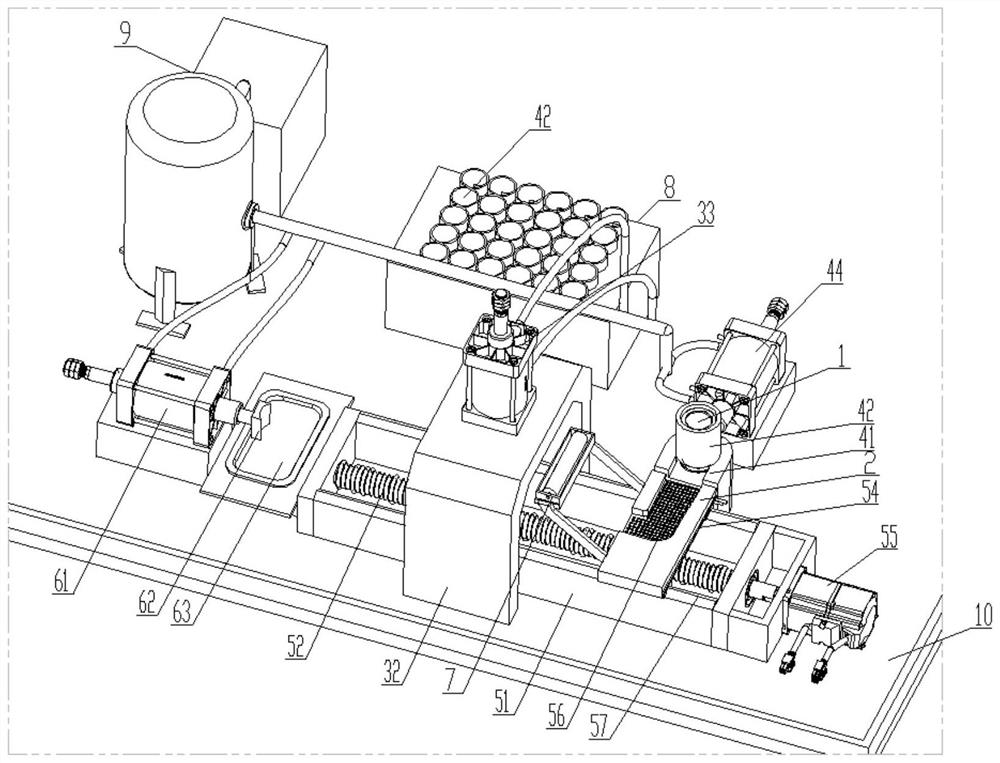

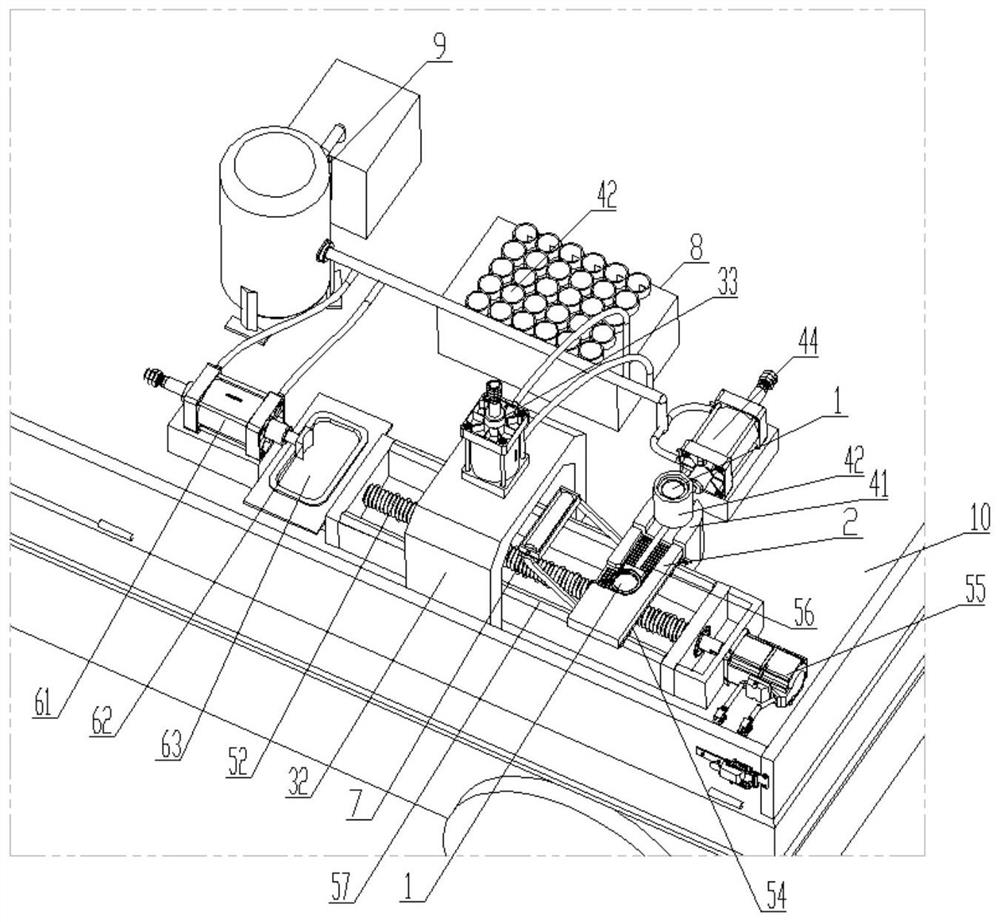

[0044] Such as Figure 1 to Figure 11 As shown, a device for preparing electrolyte standard samples on the spot uses a pressing die handle 31 to press the fluid or semi-fluid electrolyte contained in the standard sample box 1 into an electrolyte standard sample, and the standard sample box containing electrolyte 1 placed on the movable tray 2 of the material transfer mechanism, when the movable tray 2 moves to the right below the pressing die handle 31, the electrolyte standard sample is obtained by pressing down the standard sample ring 14 through the pressing die handle 31. Wherein, the standard sample box 1 comprises a bottom mold 11 with a limiting platform 12, on which the bottom mold 11 is sleeved with a spring 13 and a standard sample ring 14, and the inner wall of the standard sample ring 14 is matched with the outer wall of the bottom mold 11 in a small gap (the gap The clearance is not more than 0.2mm, under the condition that the standard sample ring 14 and the bott...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com