Molten aluminum refining effect detection method

A detection method and technology of molten aluminum, used in specific gravity measurement, measurement devices, instruments, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

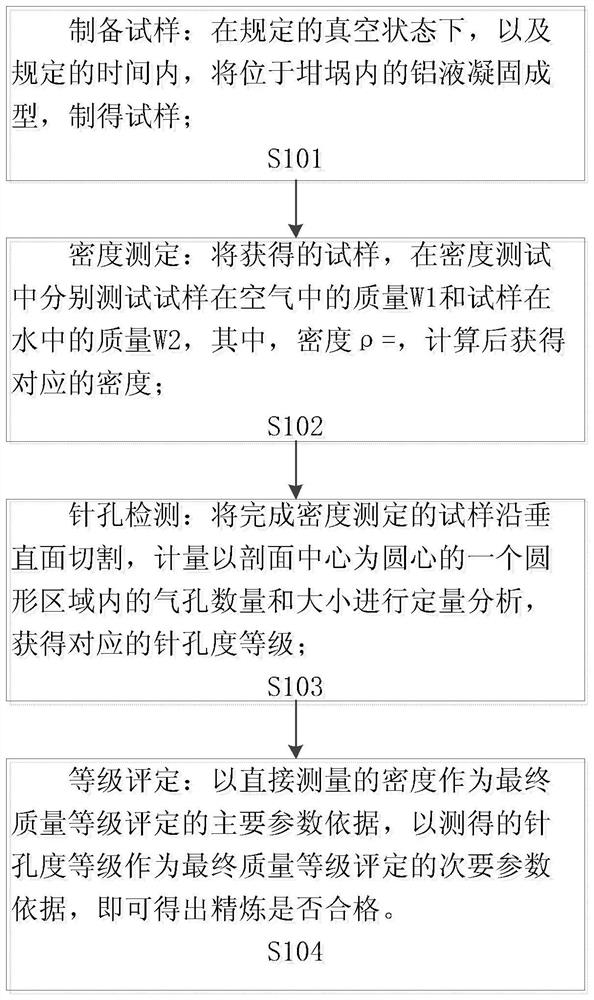

[0034] A method for detecting the refining effect of molten aluminum, comprising the following steps:

[0035] Among them, in the sample preparation process, the sample preparation at least meets the following conditions:

[0036] Step S101, prepare the sample: take a crucible with multiple metal types and the same wall thickness, preheat it to 210°C, pour the 724°C aluminum liquid taken from the same furnace into the crucible, and then cover the bell jar to start the pumping process. Vacuum device, and pump the vacuum to -9.5*10 in 130s -3 Mpa, and after reaching the vacuum degree, turn off the vacuum pump, make the system automatically suck pressure, and after the molten aluminum is solidified and cooled to room temperature, the sample is prepared;

[0037] Step S102, density measurement: first place the measuring device in water, and without placing the test object, make the measured value 0 (i.e. zero operation), then weigh the mass W1 of the sample in the air, and then p...

Embodiment 2 3

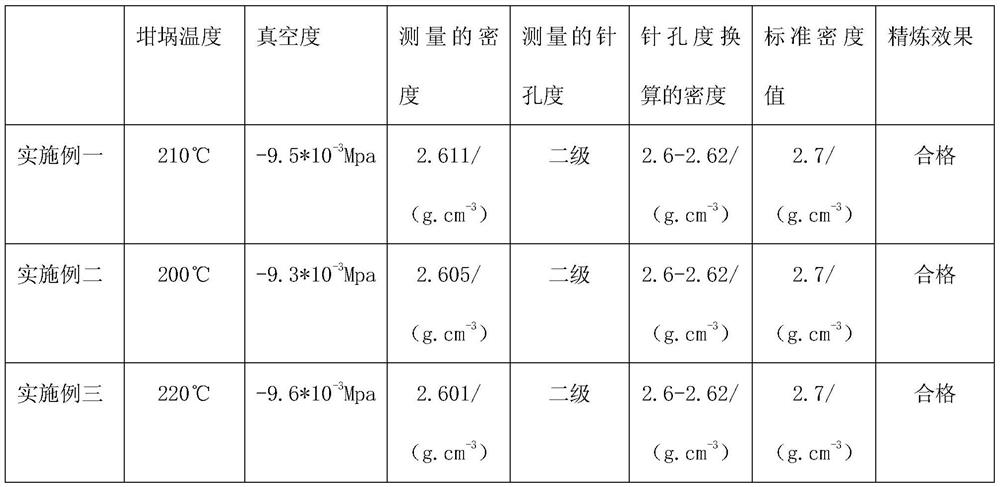

[0043] According to the measurement method of Example 1, the difference is that the preheating temperature and vacuum degree of the crucible are different, see Table 1 for details:

[0044]

[0045] From the data in Table 1, it can be seen that the measured density obtained by the above method falls within the range of the converted density of the pinhole, that is, the measured density matches the pinhole, that is, the measurement results are all qualified.

[0046] Moreover, the density measured by the measurement method of Embodiment 1 has a better matching degree with the pinhole degree, that is, the measurement result is more accurate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com