Device and method for detecting surface defects of aviation aluminum material

A detection device, aluminum technology, applied in the direction of measuring devices, optical testing flaws/defects, analyzing materials, etc., can solve problems such as deformation, deviation of detection results, troublesome data analysis, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

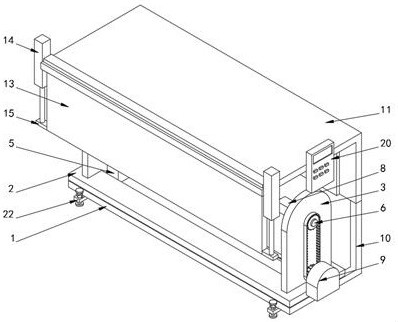

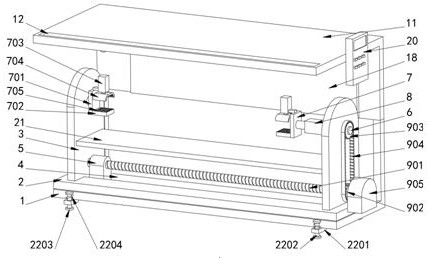

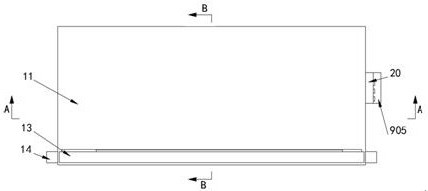

[0031] Such as Figure 1-Figure 5 As shown, the detection device and detection method for the surface defects of aviation aluminum materials proposed by an embodiment of the present invention include a base plate 1, the upper surface of the base plate 1 is slidably connected with a sliding plate 2, and the two ends of the upper surface of the sliding plate 2 are fixed with The connecting plate 3 and the middle of the sliding plate 2 are provided with a through groove 4, and one side of the upper surface of the bottom plate 1 is fixed with a threaded sleeve 5, and the upper end of the threaded sleeve 5 extends through the through groove 4 to the top of the sliding plate 2, and the two connecting Rotating shafts 6 are connected to the plates 3, and two opposite clamping assemblies 7 are arranged between the two rotating shafts 6. One of the clamping assemblies 7 is fixedly connected to the rotating shaft 6 on the same side, and the other clamping assembly 7 is electrically powere...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com