Device, method and system for testing junction temperature of power module under inversion working condition in real time

A power module, real-time testing technology, applied in the direction of measuring devices, measuring electrical variables, measuring electricity, etc., can solve the problem that the actual junction temperature data of the power module cannot be accurately and intuitively represented, and achieve the effect of ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

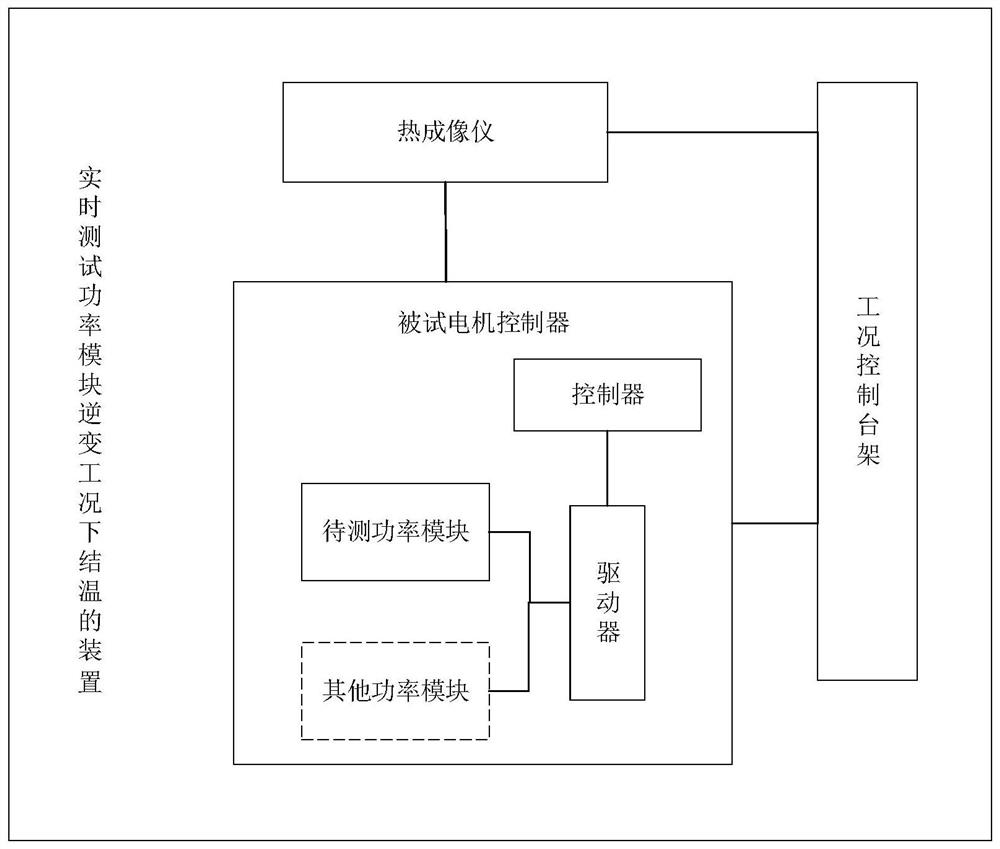

[0057] figure 1 It shows a schematic structural diagram of the device for real-time testing of the junction temperature of the power module under the inverter working condition provided by Embodiment 1 of the present invention, refer to figure 1 It can be seen that the device includes:

[0058] The tested motor controller 1 equipped with a special power module to be tested;

[0059] Working condition control frame 2, which is used to simulate a variety of operating modes for setting inverter working conditions according to control signals from the host computer; and

[0060] A thermal imager 3, which is used to collect the infrared radiation energy data emitted by the special power module to be tested, and generate and output a corresponding junction temperature distribution cloud map according to it;

[0061] The tested motor controller 1 includes:

[0062] One or more power modules, wherein at least one power module is a specially-made power module 101 to be tested after ...

Embodiment 2

[0092] Based on the device described in any one or more of the above embodiments, the present invention also provides a method for real-time testing of the junction temperature of the power module under inverter working conditions, the method includes the following operations:

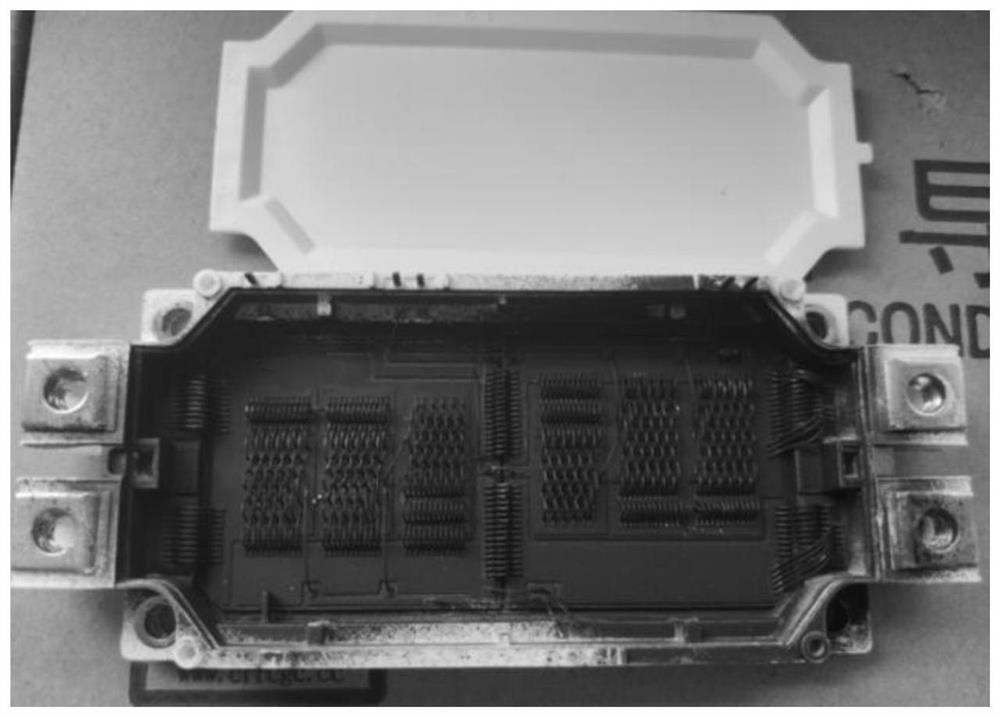

[0093] Treat the IGBT chip with a cover that meets the set emissivity requirements, and obtain a special power module to be tested for the junction temperature test;

[0094] Assemble the special power module to be tested into the box of the motor controller under test according to the configuration of the above device;

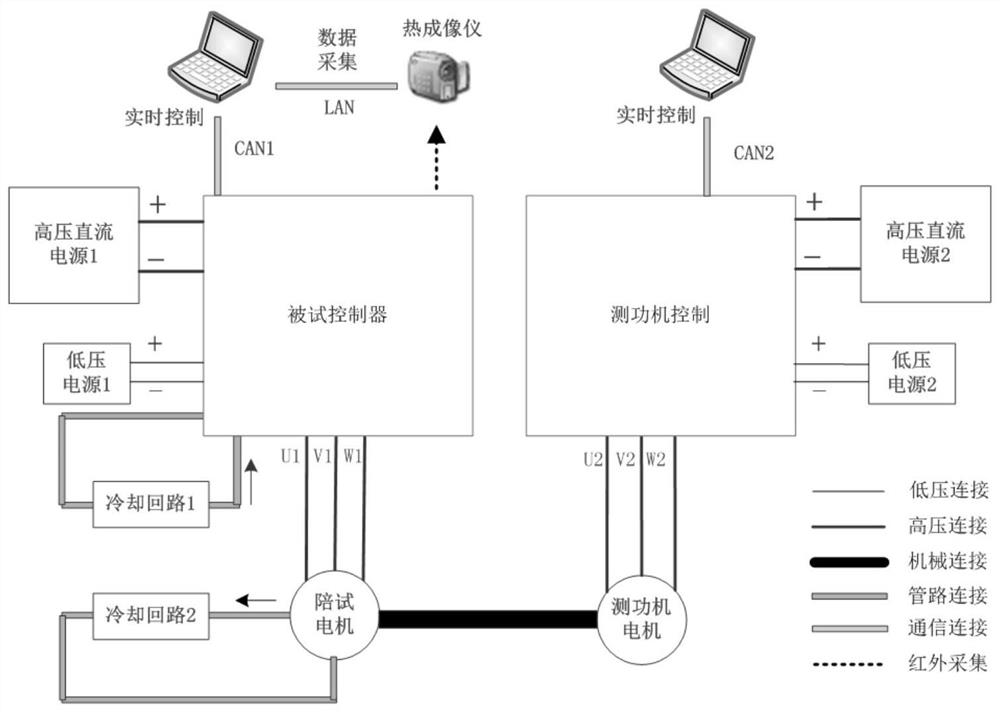

[0095] To start the test, the host computer controls the operation of the motor controller under test and the load dynamometer in the working condition control frame according to the set working condition data and the real-time junction temperature data collected by the thermal imager, so as to simulate the set multiple operating conditions;

[0096] The infrared radiation energy dat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com