Multi-working-medium direct mixing combustion device and control system and control method thereof

A combustion device and control system technology, applied in the control system, program control in sequence/logic controller, electrical program control, etc., can solve problems such as inapplicability, achieve the effect of improving work reliability and avoiding performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0074] In this embodiment, the key parameters are the pressure and temperature in the combustion chamber of the multi-working medium direct mixing combustion device, the pressure and temperature of water vapor at the outlet, and the pressure at the inlet of alcohol, air, and demineralized water; the control sequence is in the control system before starting work. The set automatic control sequence in the start-up stage, the automatic control sequence in the working stage and the automatic control sequence in the shutdown stage.

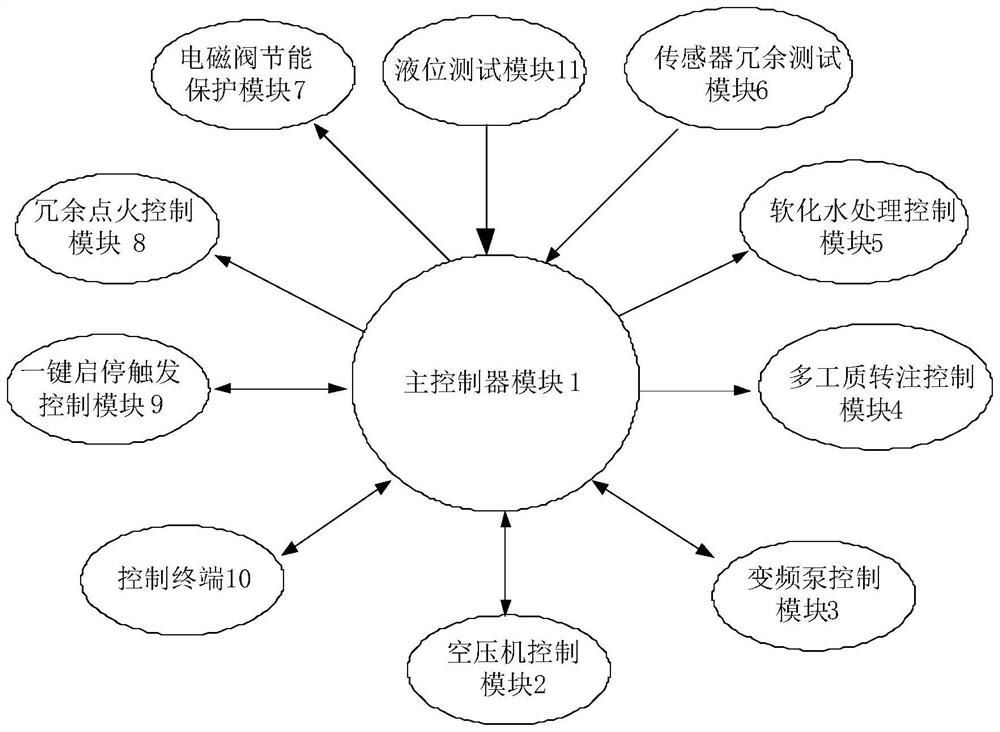

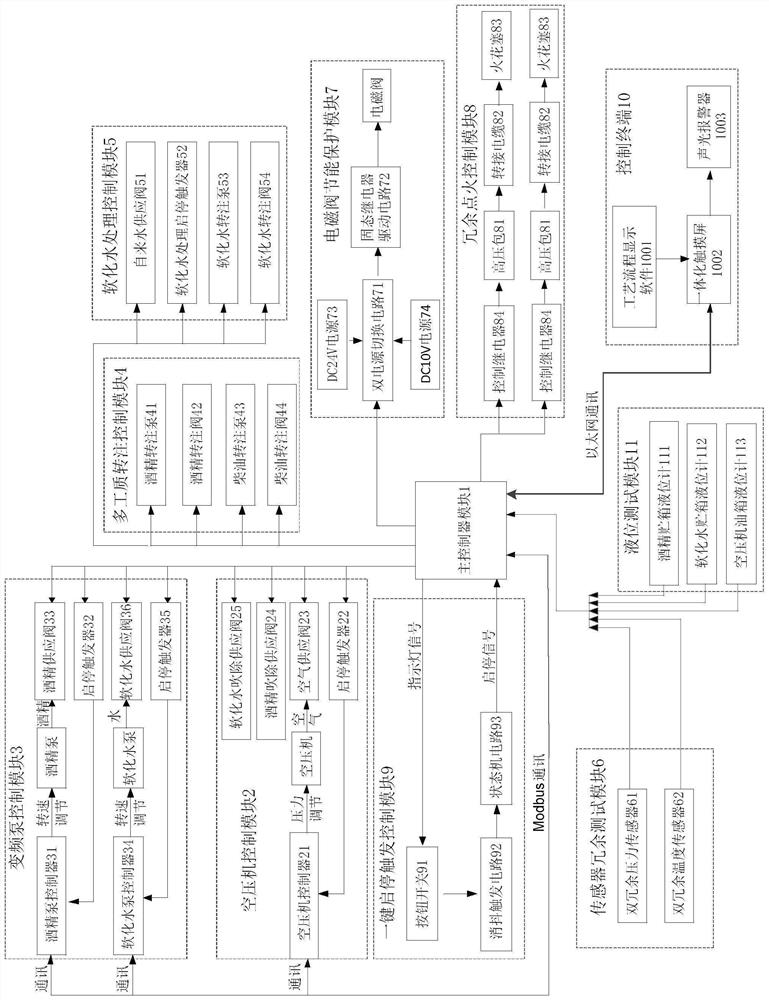

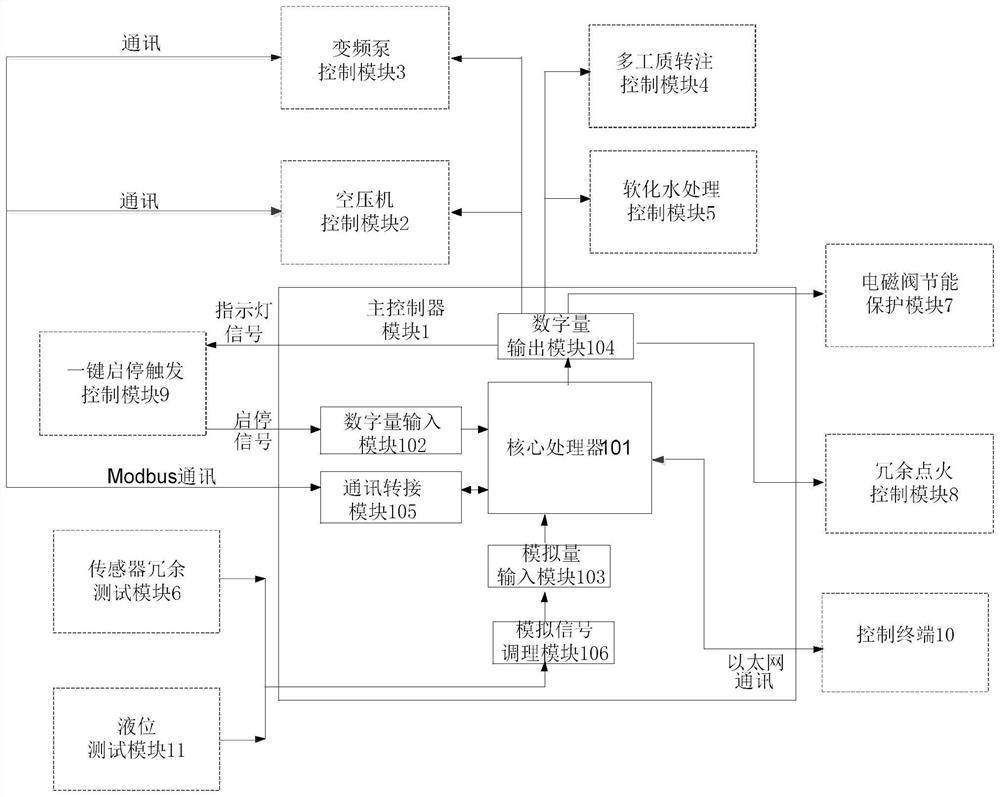

[0075] see Figure 1-Figure 3 , this embodiment provides a control system for a multi-working fluid direct mixing combustion device, the system includes a main controller module 1, an air compressor control module 2, a frequency conversion pump control module 3, a multi-working fluid transfer control module 4, a softening Water treatment control module 5, sensor redundant test module 6 and solenoid valve energy-saving protection module 7, redundant ign...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com