High-strength cold-resistant cable and manufacturing process thereof

A high-strength, cold-resistant technology, used in cable/conductor manufacturing, insulated cables, cables, etc., can solve the problems of weak cold-resistant performance, low production efficiency, and troublesome manufacturing, so as to improve strength and cold-resistant performance, improve productivity, enhance The effect of waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

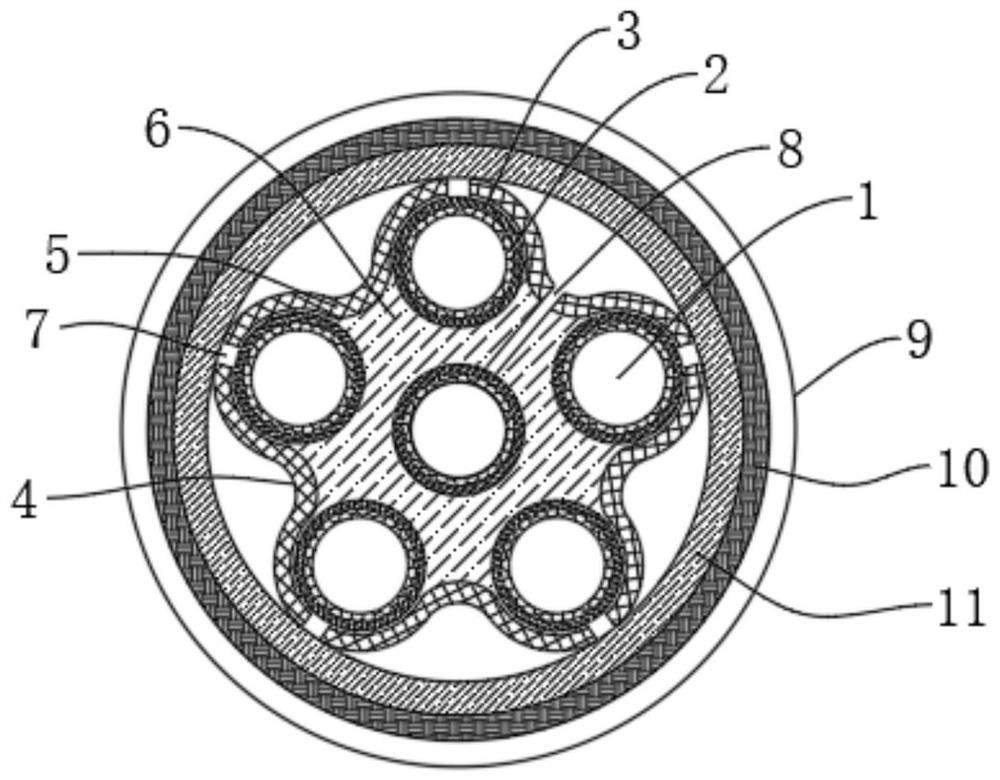

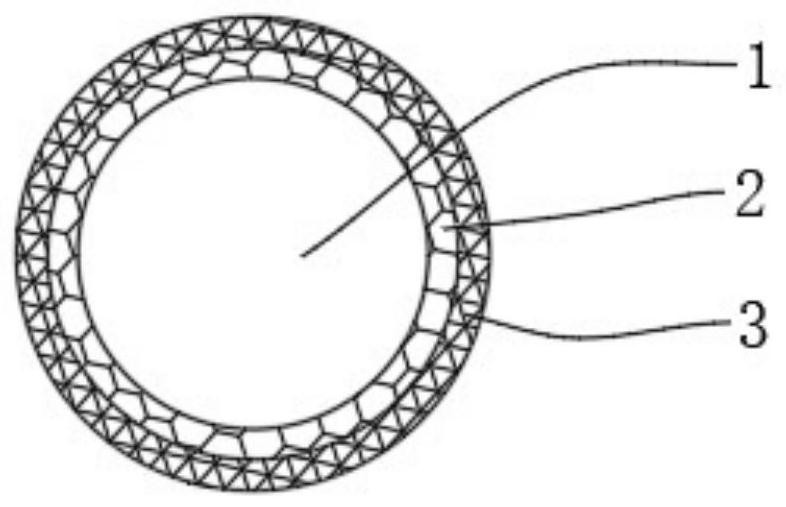

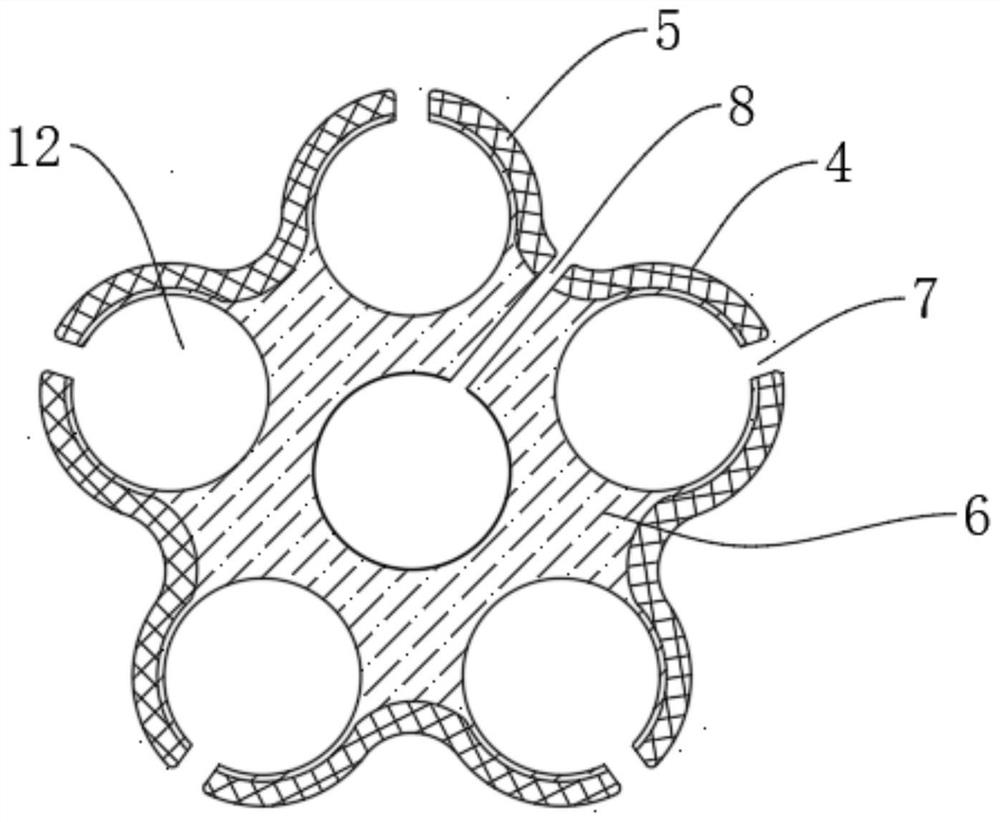

[0029] Embodiment one, by figure 1 , figure 2 and image 3 It is given that a high-strength cold-resistant cable of the present invention includes a cable core 1 and a fixed protective sheath 4, the outer wall of the cable core 1 is provided with a shielding protective layer 2, the outer wall of the shielding protective layer 2 is provided with a waterproof protective sheath 3, and the surface of the fixed protective sheath 4 is A penetrating installation groove 12 is provided. The installation groove 12 is located at the center of the circle of the fixed protective cover 4 and at the periphery of the surface. The outer peripheral installation grooves 12 are evenly distributed at equal angles. The opening 7 and the second opening 8, the cable core 1 is located in the inner cavity of the installation groove 12, the outer wall of the fixed protective cover 4 is provided with a nylon protective cover 5, and the gap between the nylon protective cover 5 and the installation groov...

Embodiment 2

[0030] Embodiment two, on the basis of embodiment one, by figure 2 Given, the shielding protection layer 2 is made of braided copper wire material, and the waterproof protective cover 3 is made of EPDM rubber material.

[0031] The shielding protection layer 2 is made of braided copper wire, and the waterproof protective sheath 3 is made of EPDM rubber, which can effectively shield external interference signals and effectively protect the cable core 1 .

Embodiment 3

[0032] Embodiment three, on the basis of embodiment one, by figure 1 Given, the insulating fireproof layer 11 is made of neoprene material, the insulation layer 10 is made of temperature-resistant silica gel material, and the outer protective layer 9 is made of nitrile rubber material.

[0033] The insulating fireproof layer 11 is made of neoprene material, the insulation layer 10 is made of heat-resistant silica gel material, and the outer protective layer 9 is made of nitrile rubber material. The design can effectively prevent the cable core 1 from fireproofing and heat preservation, and prevent the cable core from overloading. 1 Burning, causing fire.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com