LED and semiconductor laser chip suction and release device control method and device

A device control and laser technology, applied in semiconductor/solid-state device manufacturing, electrical components, circuits, etc., can solve the problems of complex sorting equipment, difficult chip sorting, small chip size, etc., to improve the technical level and batch size Production capacity, easy operation and easy to master, the effect of improving the conveying speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

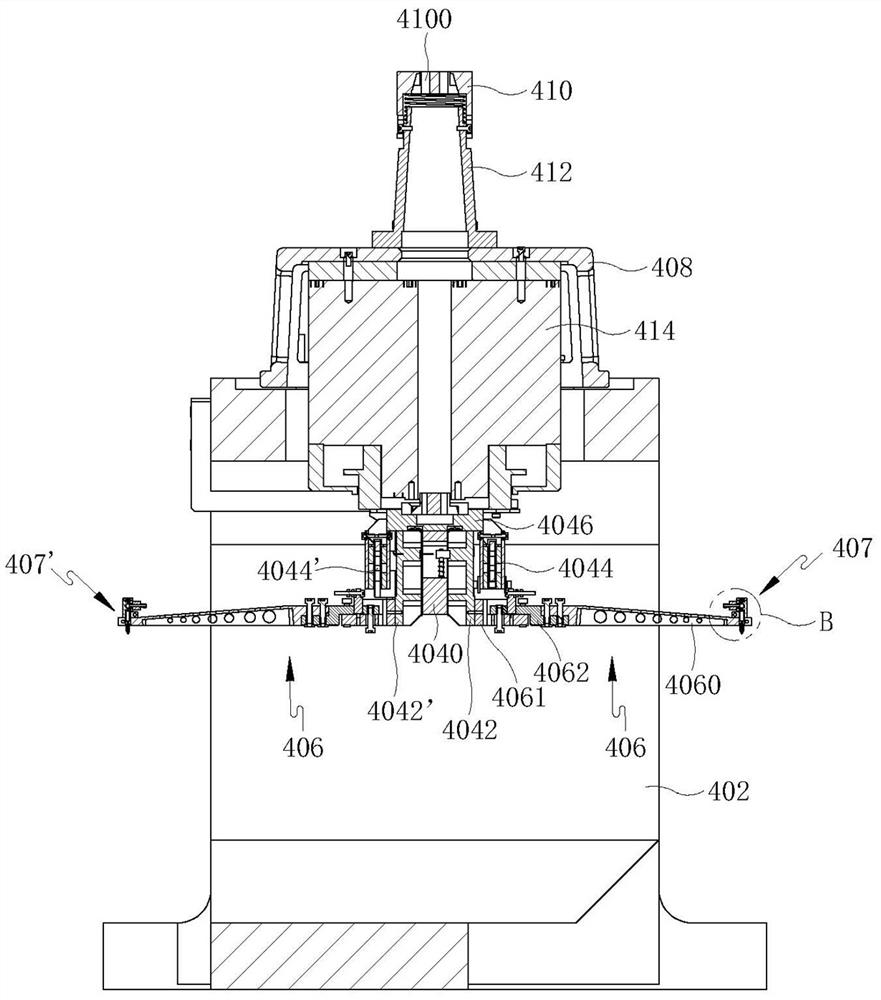

[0024] Such as figure 1 As shown, a method for controlling LED and semiconductor laser chip suction and release devices includes the following steps: (It should be noted that, for the convenience of description and understanding, the two suction nozzles will be labeled as the first suction nozzle 407 and the second suction nozzle 407' below. To distinguish, similarly, the lifting voice coil motor is distinguished by the first lifting voice coil motor 4044 and the second lifting voice coil motor 4044′, and the nozzle arm mounting frame is distinguished by the first suction nozzle arm mounting frame 4042 and the second suction nozzle arm mounting frame 4042ˊto differentiate)

[0025] S11. The first suction nozzle 407 located at the suction position sucks the chip;

[0026] S12, the second suction nozzle 407' located in the placement position puts the chips;

[0027] S13, the first suction nozzle 407 and the second suction nozzle 407′ swing 180° to exchange positions.

[0028]...

Embodiment 2

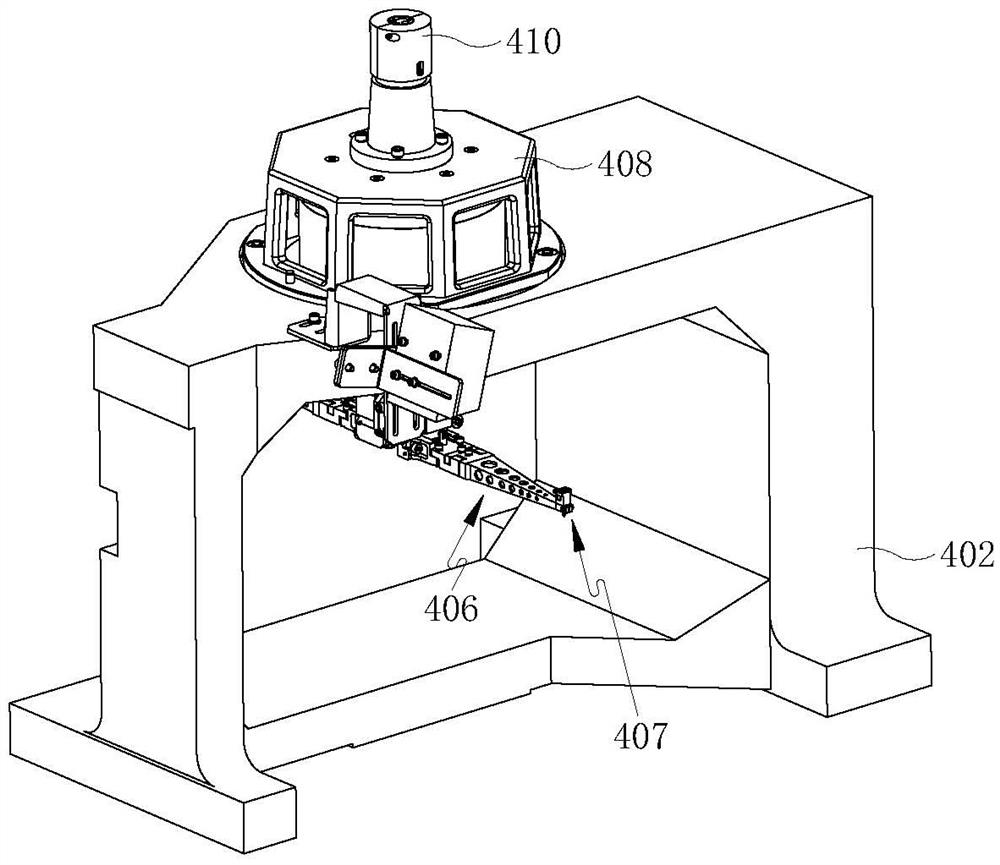

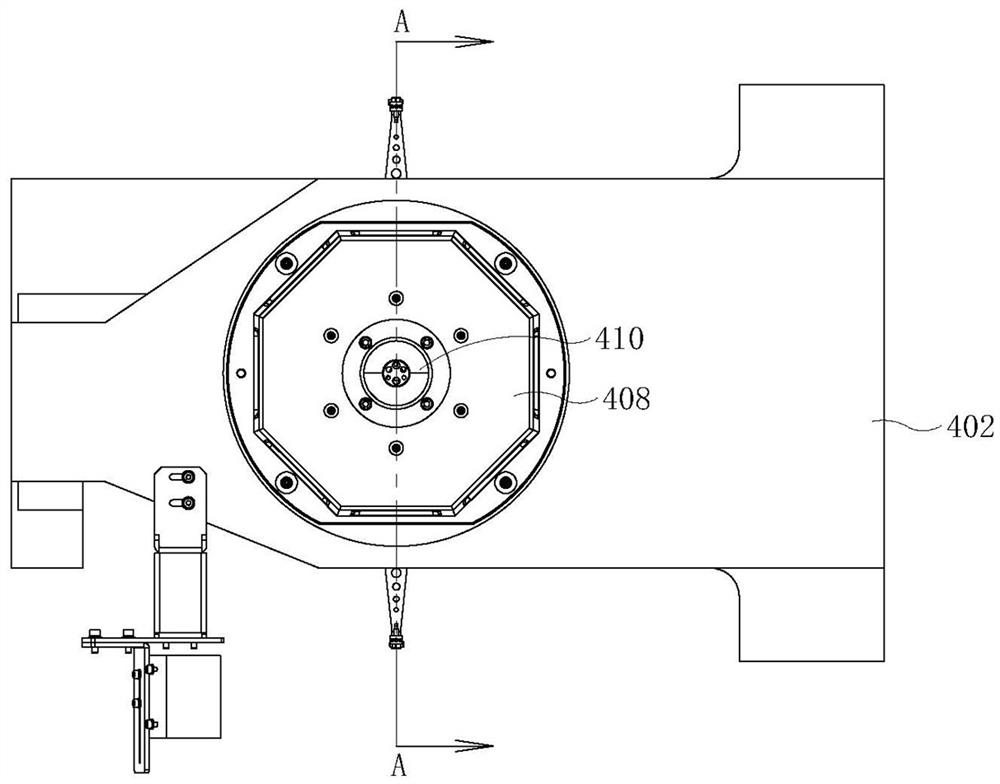

[0033] Such as figure 1and figure 2 Commonly shown, an LED and semiconductor laser chip pick-and-place device for realizing the control method of the LED and semiconductor laser chip pick-and-place device described in Embodiment 1 includes a swing arm motor 414, and the swing arm motor 414 is installed on a base 402 Above, the base 402 is a box-shaped structure viewed from the side, the swing arm motor 414 is installed in the middle of the upper side plate of the base 402, the outside of the swing arm motor 414 is provided with a motor cover 408, and a wire harness clip is provided on the motor cover 408 The head seat 412 and the wire harness chuck seat 412 are equipped with a wire harness chuck 410 , the top of the wire harness chuck 410 is provided with a wire harness hole 4100 , and the power line of the swing arm motor 414 passes through the wire harness hole 4100 . The power output shaft of the swing arm motor 414 passes through the upper side plate of the base 402 down...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com