Vibrating asymmetric distributed granule conveying five-axis support removing printer

A printer, distributed technology, applied in the direction of 3D object support structure, coating device, solid material additive processing, etc., can solve the difficult control of product quality and molding accuracy, poor surface smoothness of printed products, and poor continuity of printing process and other problems, to achieve the effect of promoting the improvement of printing efficiency, solving the uneven distribution of shear rate and high precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

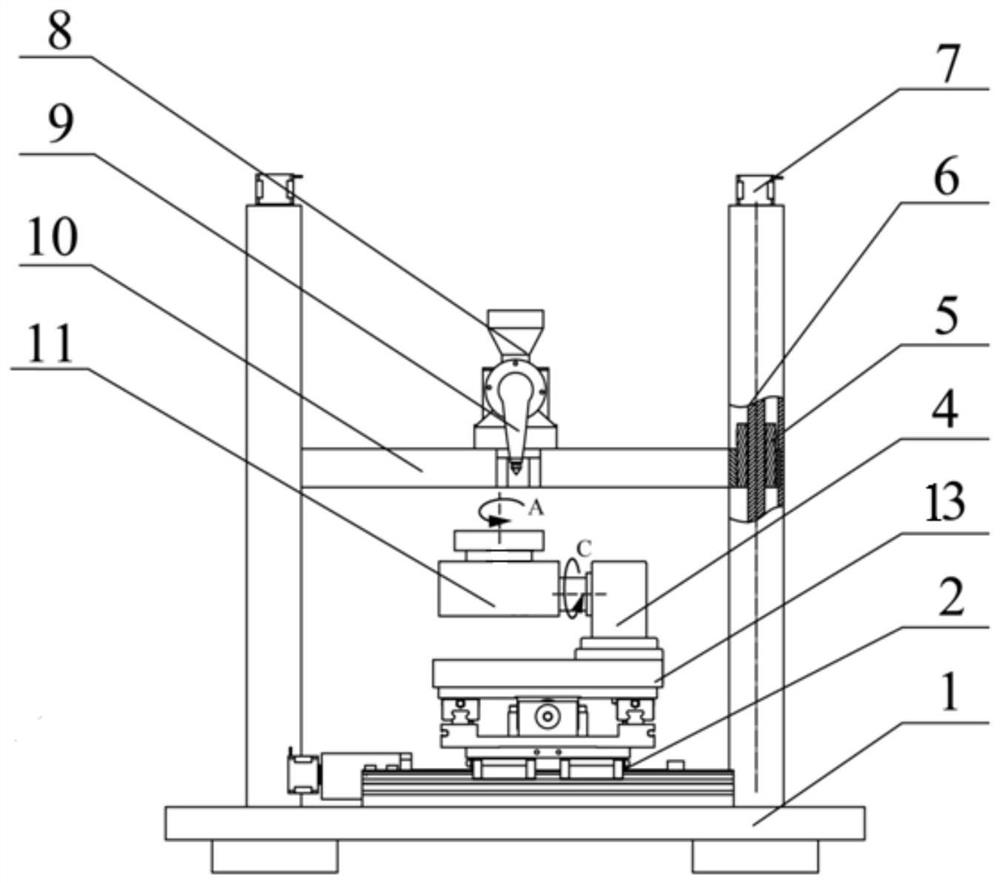

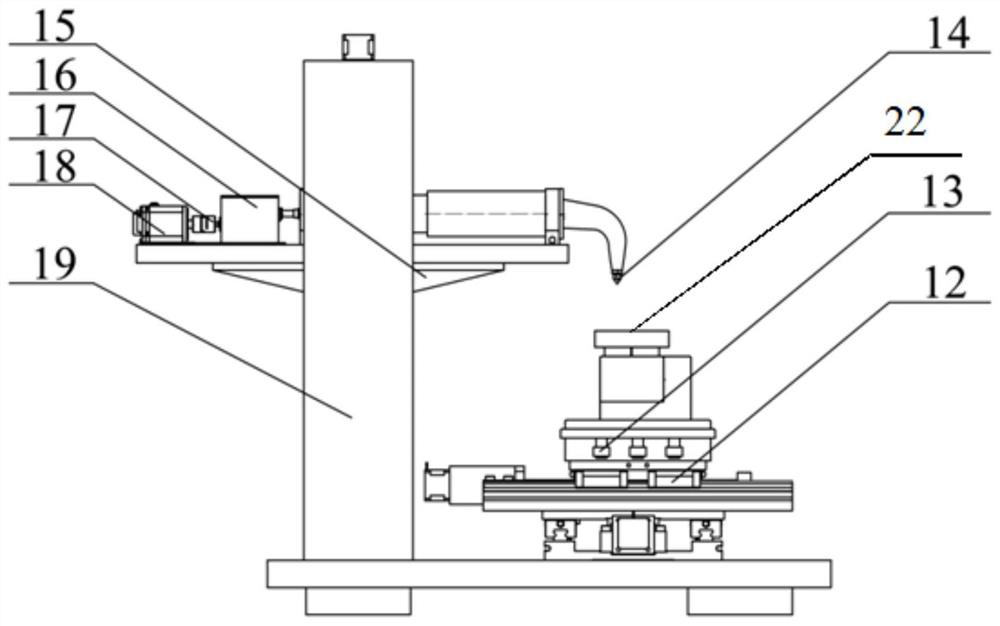

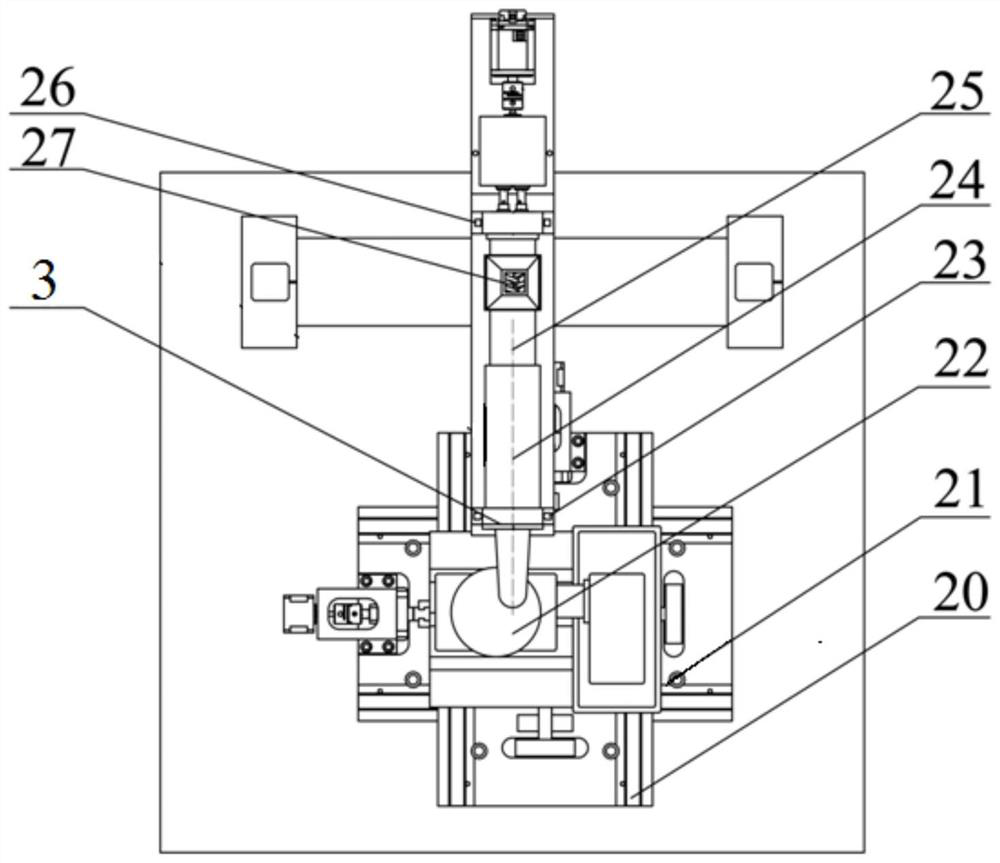

[0025] The five-axis desupporting printer for vibrating asymmetric distributed granular material conveying of the present invention, such as figure 1 , figure 2 and image 3 As shown, it includes the printer base 1, the vertical connection section of the printer base 1 is a rectangular and hollow guide column 19, the guide column 19 is connected to the Z-direction feed system, the guide column 19 is vertically connected to the support plate 10, and the support plate 10 is connected to the Z To the feed system, the vibrating feeding unit is connected to the support plate 10, the X-direction feed system 21 is connected to the printer base 1 below the support plate 10, the Y-direction feed system 20 is connected to the X-direction feed system 21, and the Y-direction feed system 20 is connected to the Y-direction feed system. Slide and connect...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com