Inertial sensor and preparation method thereof

An inertial sensor and dry etching technology, used in instruments, manufacturing microstructure devices, navigation, etc., can solve problems such as the destruction of the first dielectric layer, and meet the requirements of reducing parasitic capacitance, ensuring device reliability, and lithography accuracy. low effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0069] Hereinafter, the present invention will be described in more detail with reference to the accompanying drawings. In the various drawings, like elements are indicated with like reference numerals. For the sake of clarity, various parts in the drawings have not been drawn to scale. Also, some well-known parts may not be shown.

[0070] The invention can be embodied in various forms, some examples of which are described below.

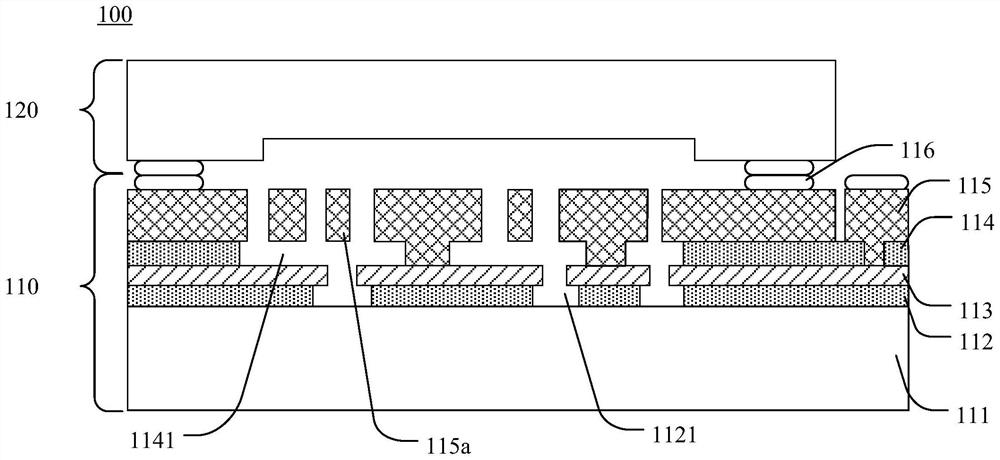

[0071] figure 1 A structural schematic diagram of an inertial sensor in the prior art is shown; as figure 1 As shown, the inertial sensor 100 includes a device chip (Device) 110 and a cap chip (Cap) 120 bonded together. Wherein, the device sheet 110 includes a first substrate 111, a first dielectric layer 112, a first conductive layer 113, a second dielectric layer 114, a second conductive layer 115 and a bonding structure 116 from bottom to top. The cap sheet 120 is bonded to the device sheet 110 through the bonding structure 116 .

[0072] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com