Corrosion-resistant glass fiber reinforced polypropylene material and preparation method thereof

A polypropylene material and corrosion-resistant technology, which is applied in the field of glass fiber reinforced polypropylene materials and their preparation, can solve the problems of mechanical properties and heat resistance properties that are not as good as nylon materials, so as to improve mechanical properties, protect interface stability, improve Effect of impact strength and tensile strength

Active Publication Date: 2022-05-17

SHANGHAI KINGFA SCI & TECH +1

View PDF5 Cites 1 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Polypropylene materials have better chemical resistance, but conventional glass fiber reinforced polypropylene materials are not as good as nylon materials in terms of mechanical properties and heat resistance

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

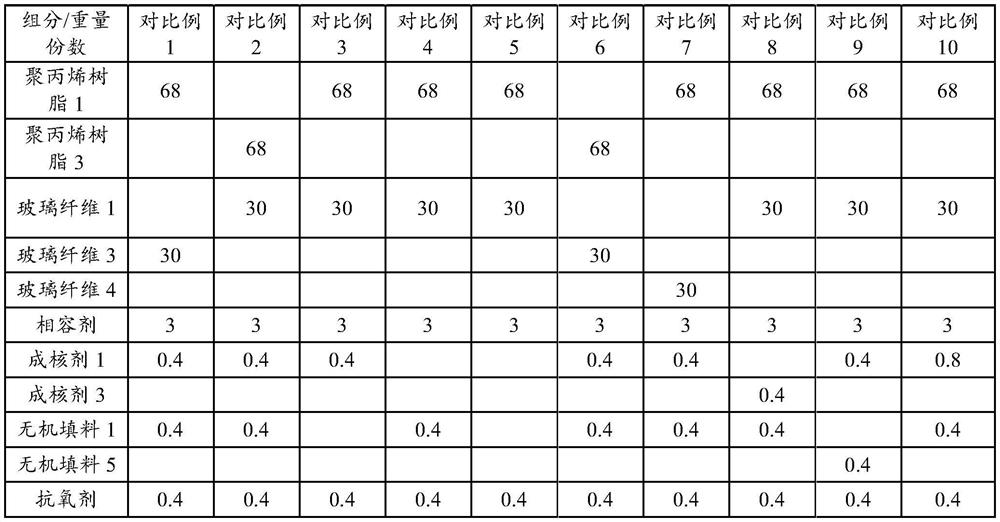

Comparison scheme

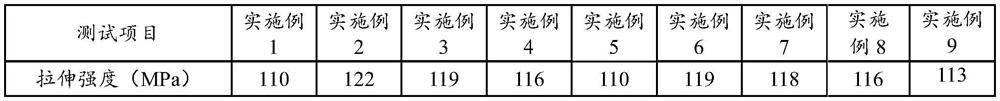

Effect test

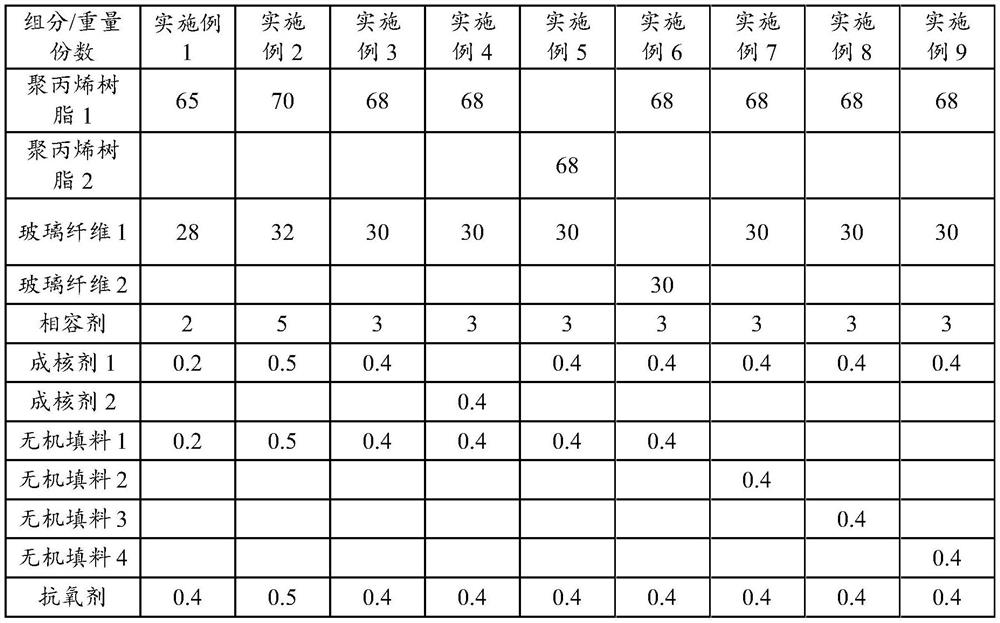

Embodiment 1~9

[0054] The components and amounts of the corrosion-resistant glass fiber reinforced polypropylene material described in each example are shown in Table 1.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Login to View More

Abstract

The invention relates to a corrosion-resistant glass fiber reinforced polypropylene material and a preparation method thereof, and belongs to the technical field of high polymer materials. In the components of the glass fiber reinforced polypropylene material disclosed by the invention, the polypropylene resin with high tensile strength and the superfine glass fiber are compounded, so that the impact strength and the tensile strength of a product can be effectively and synergistically improved, and the glass fiber reinforced polypropylene material meets the basic mechanical property requirements and the heat resistance requirements of existing automobile water chamber parts; the special nucleating agent and the inorganic filler are matched to achieve synergistic interaction, organic solvents such as ethylene glycol are effectively prevented from entering an interface of polypropylene resin and glass fiber, the interface stability of the whole material is protected, and finally the corrosion resistance of the product reaches the application standard; in addition, the crystallinity of the polypropylene resin can be effectively regulated and controlled, and the mechanical property of the obtained product is further improved. The invention also provides a preparation method and application of the corrosion-resistant glass fiber reinforced polypropylene material.

Description

technical field [0001] The invention belongs to the field of polymer materials, and in particular relates to a corrosion-resistant glass fiber reinforced polypropylene material and a preparation method thereof. Background technique [0002] With the rapid development of the automobile industry, the main direction of automobile research is to reduce weight, save energy, reduce emissions, and improve safety performance. A major development trend, the demand of the automotive market has shifted to lighter weight sports vehicles, utility vehicles and other light vehicles, which also promotes the development of functional plastics to better performance. The car water chamber is used as the heat dissipation device of the car, and the coolant glycol has to undergo alternating high and low temperature changes. Therefore, the water chamber material is required to be resistant to chemical corrosion and high temperature resistance, as well as the mechanical properties of the material. ...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C08L23/12C08L51/06C08K7/14C08K5/053C08K7/04C08J5/04

CPCC08J5/043C08J2323/12C08J2451/06C08K7/14C08K5/053C08K7/04C08K2201/003

Inventor 王海霞陈平绪叶南飚李国明孙刚

Owner SHANGHAI KINGFA SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com