Preparation method and application of flexible current collector derived from carbon paper

A flexible current collector and carbon paper technology, applied in the field of materials, can solve the problems of easy bending of carbon paper, achieve the effect of improving flexibility, good flexibility and mechanical strength, and increasing utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Preparation method of carbon paper derived flexible collector, comprising the following steps:

[0026] 1) Choose a temperature-resistant 300 °C polyimide tape, the size is suitable for the carbon paper to be fitted, the polyimide tape is fitted with the three-dimensional woven carbon paper, and the pressure is applied to make the two closely fitted, but the pressure applied cannot cause the carbon paper and tape to break;

[0027] 2) Carefully peel off the polyimide tape at a peeling speed of 0.3-0.5cm / s, and the ultra-thin carbon paper obtained is a flexible collector derived from carbon paper with good flexibility and mechanical strength.

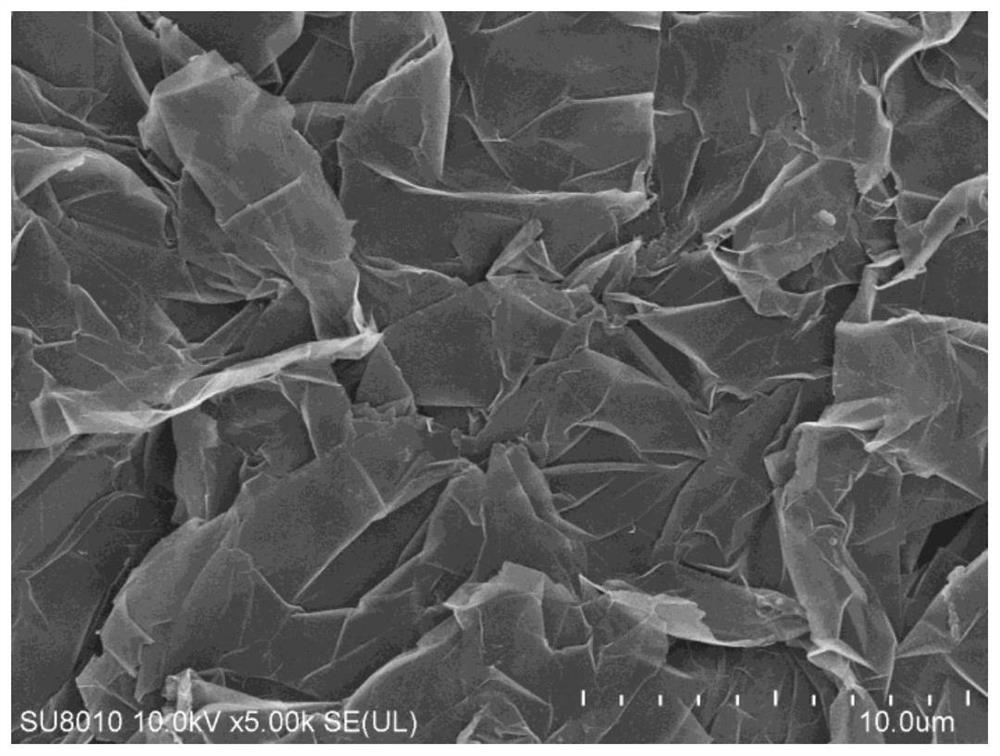

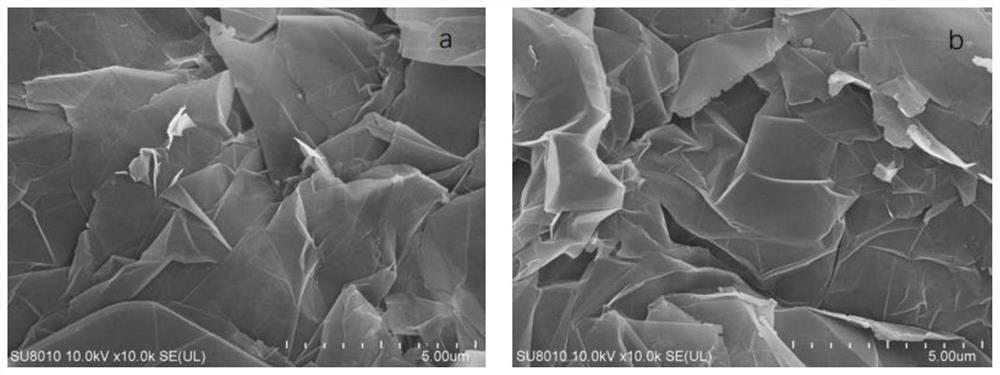

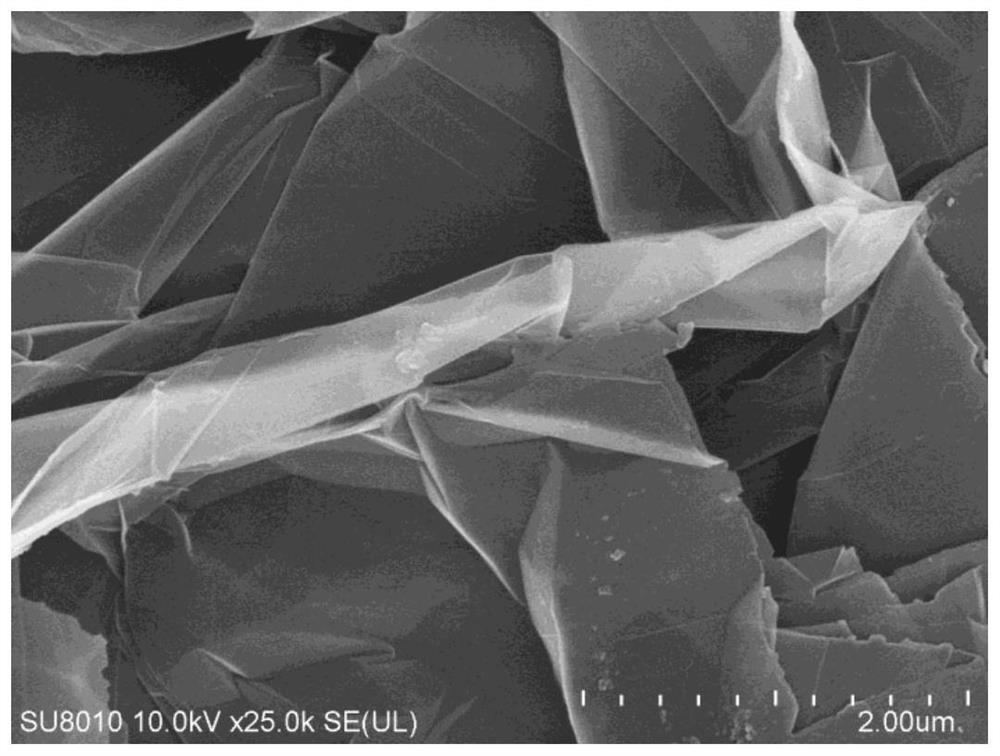

[0028] Figure 1 Scanning electron microscopy diagram of flexible fluid collector derived from the resulting carbon paper at magnification of 10.0KV*5.0K, Figure 2 (a)、 Figure 2 (b) A scanning electron microscopy diagram of the flexible collector derived from the resulting carbon paper at magnification of 10.0KV*10.0K times, Figure 3...

Embodiment 2

[0031] Example 2 to proportional

[0032] 1) Select polypropylene tape, the size is suitable for the carbon paper to be fitted, the polypropylene tape is fitted with the three-dimensional woven carbon paper, and the pressure is applied to make the two closely fitted, but the pressure applied cannot cause the carbon paper and tape to break;

[0033] 2) Carefully peel off the polypropylene tape at a peeling speed of 0.3-0.5cm / s to obtain the carbon paper collection fluid after the polypropylene tape is peeled off.

[0034] Figure 6 Carbon paper collector after stripping polypropylene tape prepared for Example 2 and carbon paper collecting fluid derived from Example 1 at 300 ° C thermal stability comparison diagram, the left side of the tray is the carbon paper collection fluid after polypropylene tape peeling, and the right side is the carbon paper derived from the polyimide tape peeling obtained by flexible collector fluid. Pass Figure 6 The results of the thermal stability experi...

Embodiment 3

[0036] A carbon paper derived flexible collector as a test of the conductivity of electrode materials.

[0037] Figure 7 For the test plot of the conductivity of the carbon paper-derived flexible collector as the electrode material, two pieces of carbon paper-derived flexible collector are connected into the circuit, and the power supply battery and the small fan of the electrical appliance are connected in series, and the rotation of the small fan can be observed. It can be seen that the flexible collector material derived from the carbon paper has good electrical conductivity.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com