White titanium-free film coating material as well as preparation method and preparation application thereof

A coating material, titanium film technology, applied in sugar-coated pills, pharmaceutical formulations, inorganic non-active ingredients, etc., can solve the problems of titanium dioxide application limitations, and achieve the effect of improving market competitiveness, increasing application scope, and good film-forming properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] First of all, the original design intention of the present invention: the coating material in the prior art contains titanium dioxide, and titanium dioxide is listed in class II carcinogens, causing a bad impact on human life and health, etc., in order to solve the above problems, the present invention provides a white titanium-free film coating material, a white titanium-free film coating material preparation method, a specific embodiment of the preparation of a white titanium-free film coating material.

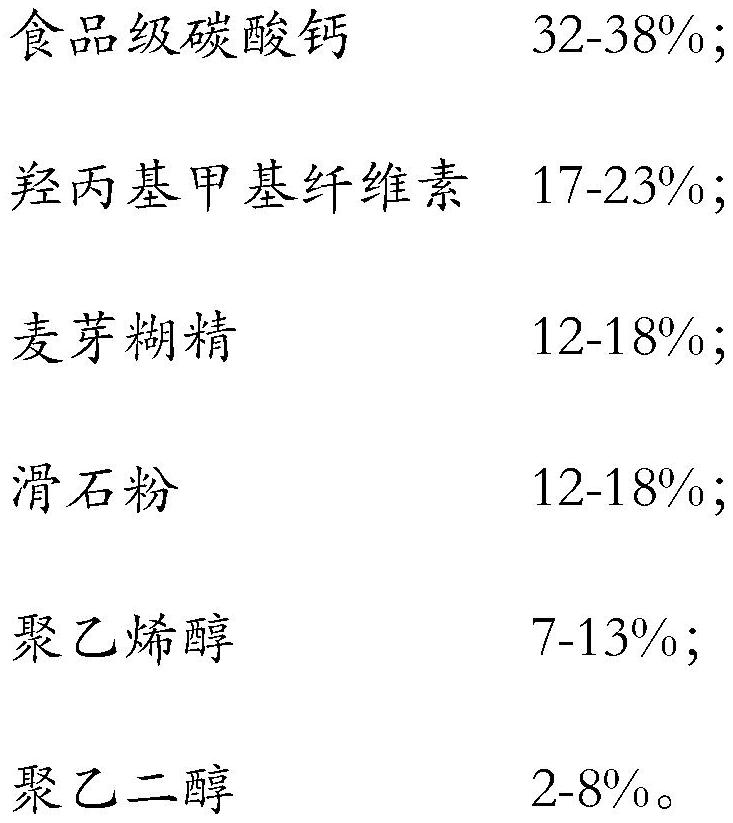

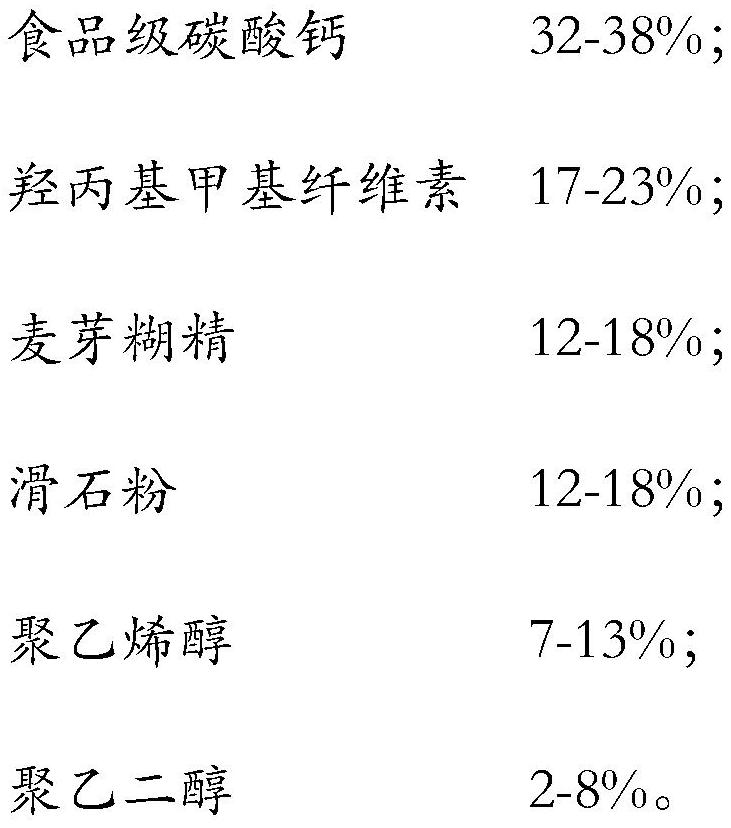

[0019] A white titanium-free film coating material that comprises the following weight percentages of raw materials:

[0020]

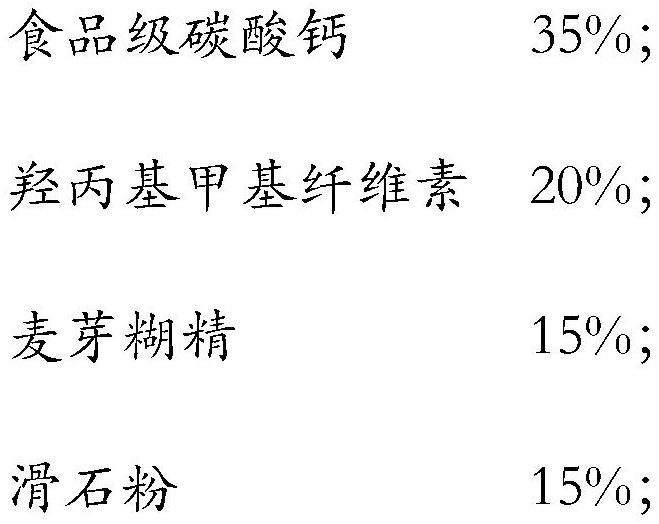

[0021]

[0022]The above weight percentage of raw materials made of white titanium-free film coating material through food grade calcium carbonate instead of titanium dioxide, greatly reducing the titanium dioxide content and other class II carcinogens, in order to achieve a good coverage rate brought by carbon dioxide, the present embodimen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com