Low-temperature zero-pressure anhydrous rubber low-oxygen catalytic regeneration method

An oxygen catalysis, zero-pressure technology, applied in the direction of plastic recycling, recycling technology, etc., can solve the problems of high safety, high equipment cost, large amount of waste gas and waste water, etc., to reduce energy consumption cost, low equipment cost, and small stirring resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

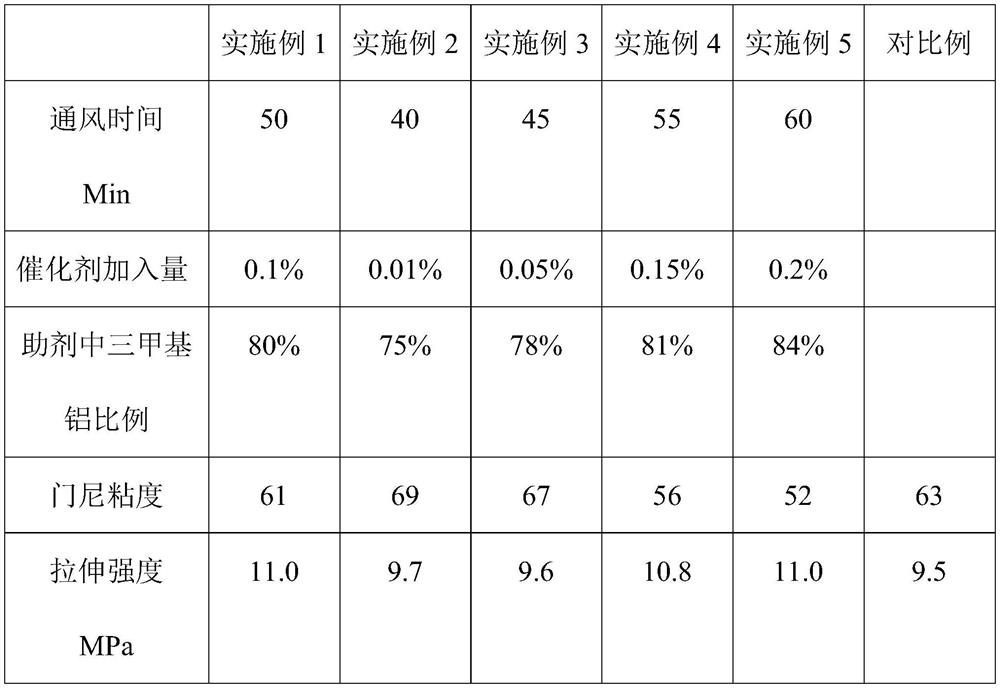

Examples

Embodiment 1

[0020] A low-temperature zero-pressure anhydrous rubber low-oxygen catalytic regeneration method, comprising the following steps:

[0021] 1) After the waste rubber is crushed, rubber powder is obtained;

[0022] 2) The rubber powder is added to the low-temperature container, and the auxiliary agent is added, and the reaction is carried out by heating. During the reaction process, the mixed gas of low concentration oxygen is continuously introduced. During the reaction process, no water is added, and no water vapor is passed through. The reaction time is about 1 hour. After completion, cooling to obtain recycled rubber powder;

[0023] Auxiliaries include catalysts and softeners, excluding water, and the composition of catalysts includes trimethylaluminum and polyamines;

[0024] During the reaction, the heating temperature is higher than the softening point of the softening agent and not higher than 140°C.

[0025] Among them, the low temperature container can be an open re...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap