Two-component polyurethane marking paint and preparation method thereof

A two-component polyurethane and marking paint technology, applied in the field of paint, can solve the problems of paint film thickness and hardness decrease, large performance difference, flexibility and adhesion decrease, etc., to achieve increased adhesion and flexibility, reflective Long-lasting and long-lasting effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

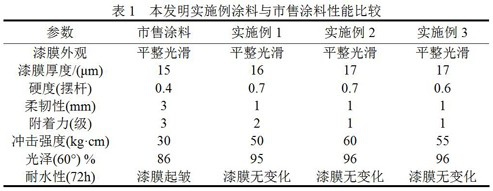

Examples

Embodiment 1

[0038] Weigh 1.5kg of Degaroute 465 acrylic resin, mix it with 3kg of hydroxy acrylic resin, add 0.05kg of initiator tert-butyl peroxybenzoate, heat up to 90°C and react for 0.5h, then add 0.5kg of Degaroute 465 acrylic resin and 0.005kg of resistance. The polymerization agent benzoquinone was continued to react for 1h.

[0039] After the reaction, ethyl acetate was added to the reaction product, diluted to a solid content of 50%, and the insoluble matter was filtered off to obtain a modified hydroxyacrylic resin.

[0040] The appearance of the modified hydroxy acrylic resin prepared above is colorless and transparent liquid. After testing, the chromaticity (iron-cobalt colorimetry) is less than or equal to 1, the viscosity (coating-4 cups) is 95s, the fineness is less than or equal to 15 μm, and the solid content is 50±1%.

[0041] Weigh 0.02kg of defoamer BYK-023, 0.03kg of leveling agent BYK-308, 0.4kg of titanium dioxide, 1.8kg of internally mixed glass beads, 0.03kg of di...

Embodiment 2

[0045]Weigh 1.65kg of Degaroute 465 acrylic resin, mix it with 4kg of hydroxy acrylic resin, add 0.06kg of initiator tert-butyl peroxybenzoate, heat up to 105°C and react for 0.75h, then add 0.35kg of Degaroute 465 acrylic resin and 0.035kg of resistance. The polymerization agent benzoquinone continued to react for 1.25h.

[0046] After the reaction, ethyl acetate was added to the reaction product, diluted to a solid content of 55%, and the insoluble matter was filtered off to obtain a modified hydroxyacrylic resin.

[0047] The appearance of the modified hydroxy acrylic resin prepared above is colorless and transparent liquid. After testing, the chromaticity (iron-cobalt colorimetry) is less than or equal to 1, the viscosity (coating-4 cups) is 95s, the fineness is less than or equal to 15 μm, and the solid content is 55±1%.

[0048] Weigh 0.03kg of defoamer BYK-023, 0.035kg of leveling agent BYK-308, 0.5kg of titanium dioxide, 1.5kg of internally mixed glass beads, 0.04kg of...

Embodiment 3

[0052] Weigh 1.8kg Degaroute 465 acrylic resin, mix with 5kg hydroxy acrylic resin, add 0.07kg initiator tert-butyl peroxybenzoate, heat up to 120°C and react for 1h, then add 0.2kg Degaroute 465 acrylic resin and 0.07kg polymerization inhibitor agent benzoquinone, and continue to react for 1.5h.

[0053] After the reaction, ethyl acetate was added to the reaction product, diluted to a solid content of 45%, and the insoluble matter was filtered off to obtain a modified hydroxyacrylic resin.

[0054] The appearance of the modified hydroxy acrylic resin prepared above is colorless and transparent liquid. After testing, the chromaticity (iron-cobalt colorimetry) is less than or equal to 1, the viscosity (coating-4 cups) is 95s, the fineness is less than or equal to 15 μm, and the solid content is 45±1%.

[0055] Weigh 0.04kg of defoaming agent BYK-023, 0.04kg of leveling agent BYK-308, 0.6kg of titanium dioxide, 2kg of internally mixed glass beads, 0.05kg of dispersant BYK-P105 a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com